Device for reworking the running surface of a rail head by machining

A technology for machining and running surfaces, applied in metal processing equipment, rails, track maintenance, etc., can solve problems such as large design costs, uneven machining, etc., and achieve the effect of reducing design work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

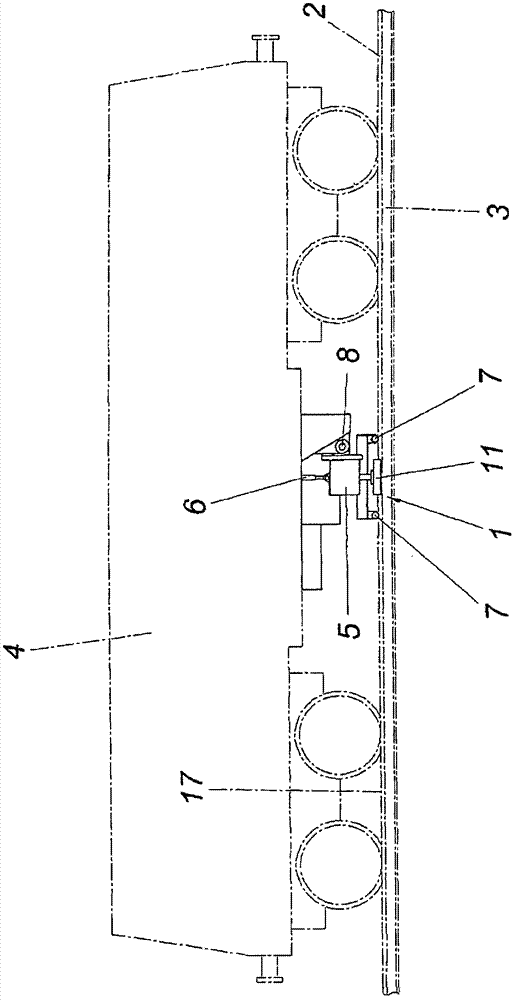

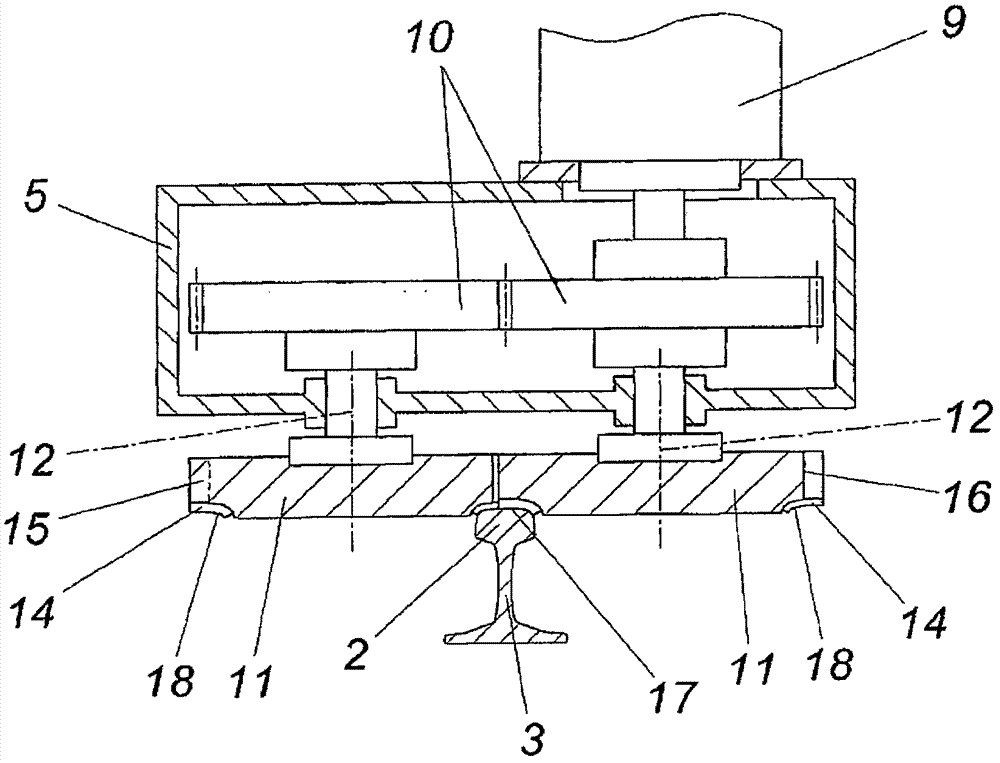

[0019] as available from figure 1 As inferred in , the device 1 according to the invention for reworking the rail head 2 of a rail 3 of a railway track by machining is arranged on a rail vehicle 4 , and the device 1 moves along the rail 3 with the help of the rail vehicle 4 . The device 1 has a frame 5 mounted on the rail vehicle 4 , which is vertically adjustable with the aid of a lifting drive 6 on the rail vehicle 4 and supported via guide rollers 7 on the rail head 2 . These guide rollers 7 not only guide the frame 5 vertically relative to the rail 3 , but also guide the frame 5 transversely.

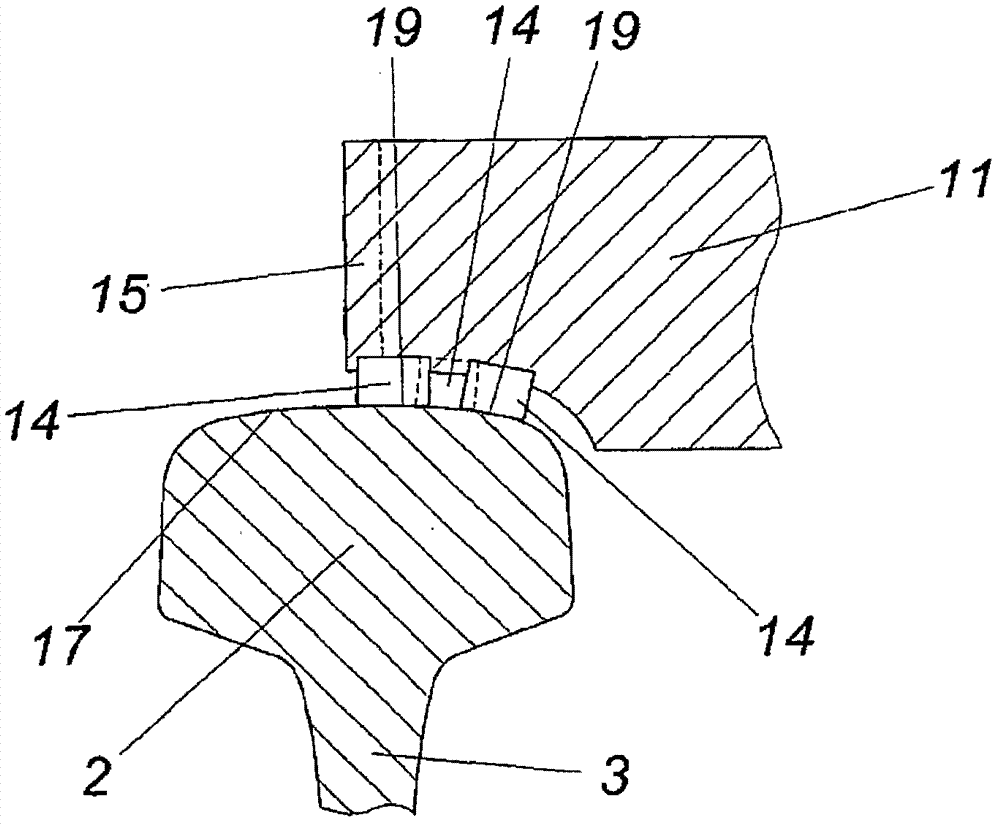

[0020] according to figure 2 , the frame 5 receives a gearbox 10 connected to a rotary drive 9 to enable two machining tools to be driven synchronously in opposite directions in the manner of an end mill 11 , said frame 5 being connected to a rail vehicle 4 by a shaft 8 With a vertical shift, however, this is not required. The axes of rotation 12 of these face milling cutters 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com