Winding core, winding reel and band-winding method

A technology for winding tapes and tapes, which is applied in the direction of winding strips, packaging, and conveying filamentous materials, etc. It can solve the problems of package deformation, impact failure, bending, etc., and achieve cost reduction and prevent winding collapse. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment )

[0096] Hereinafter, examples of the winding core, winding reel, and tape body winding method of the present invention will be described together with comparative examples.

Embodiment 1)

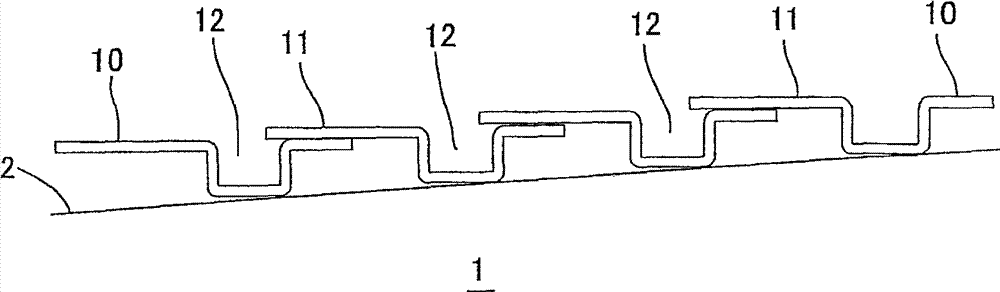

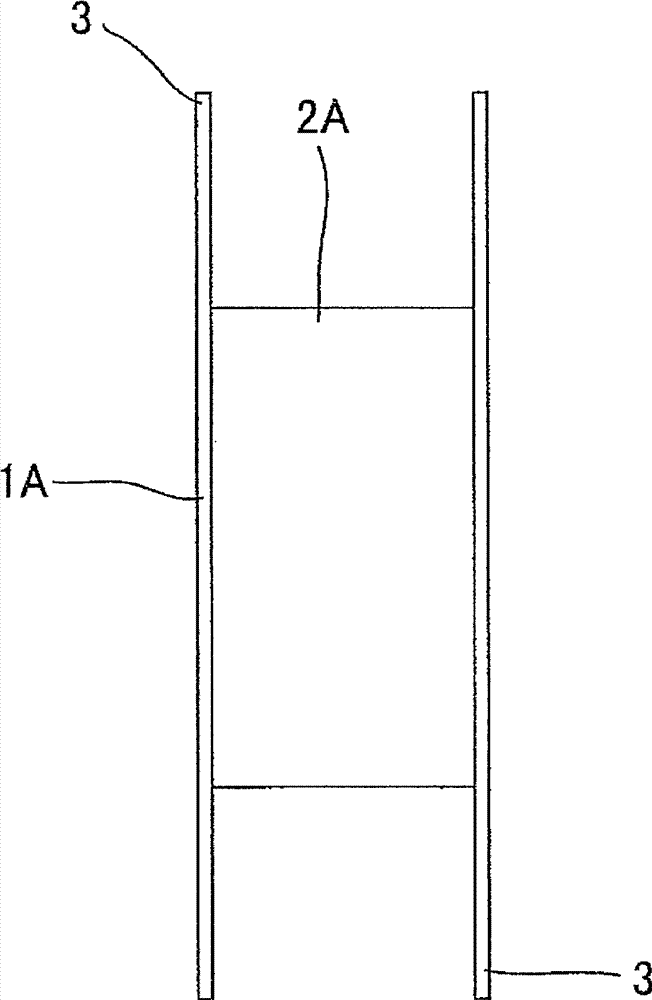

[0098] First, an empty winding core is fitted to the drive shaft of the winding device, the end of the carrier tape is wound on the winding core, and the carrier tape is wound around the guide roller of the winding device under tension. On the peripheral surface of the winding core, a 1.5° taper is formed in the radially outward direction. In addition, as the carrier tape, a tape width of 8 mm, a depth of each pocket of 1.42 mm, and a type in which a plurality of perforations were perforated at intervals on one side in the longitudinal direction of the tape were used.

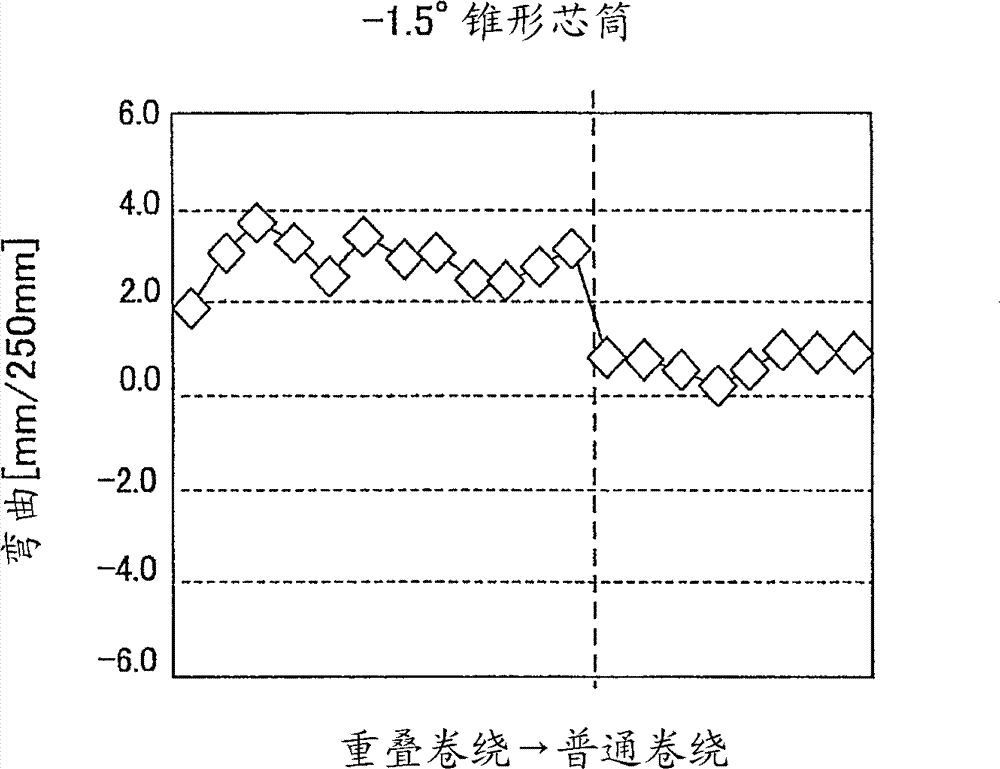

[0099] After the carrier tape is wound on the guide roller of the winding device, the winding device is driven to wind the carrier tape to the peripheral surface of the winding core while moving to the left or right, and the bending of the carrier tape is measured, and Summarize the results of this measurement in the Figure 14 , Figure 15 in the chart. During the winding of the carrier tape, such as Figu...

Embodiment 2)

[0103] It is basically the same as in Example 1, but a 5° taper is formed on the peripheral surface of the winding core in the radially outward direction. Others measure the bending of carrier tape identically with embodiment 1, and its measurement result is summarized in Figure 14 , Figure 16 in the chart. Figure 16 The dotted line near the center of indicates the change point of the carrier tape from the overlapping winding to the normal winding.

[0104] As a result of measuring the warp of the carrier tape, the warp of the carrier tape was small, and extremely good results were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com