Embossing device of embossing machine

An embossing machine and embossing technology, applied in decorative arts, mechanical processing/deformation, textiles and papermaking, etc., can solve the problems of inconvenient replacement and operation, and achieve the effect of saving time, reasonable design and great benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

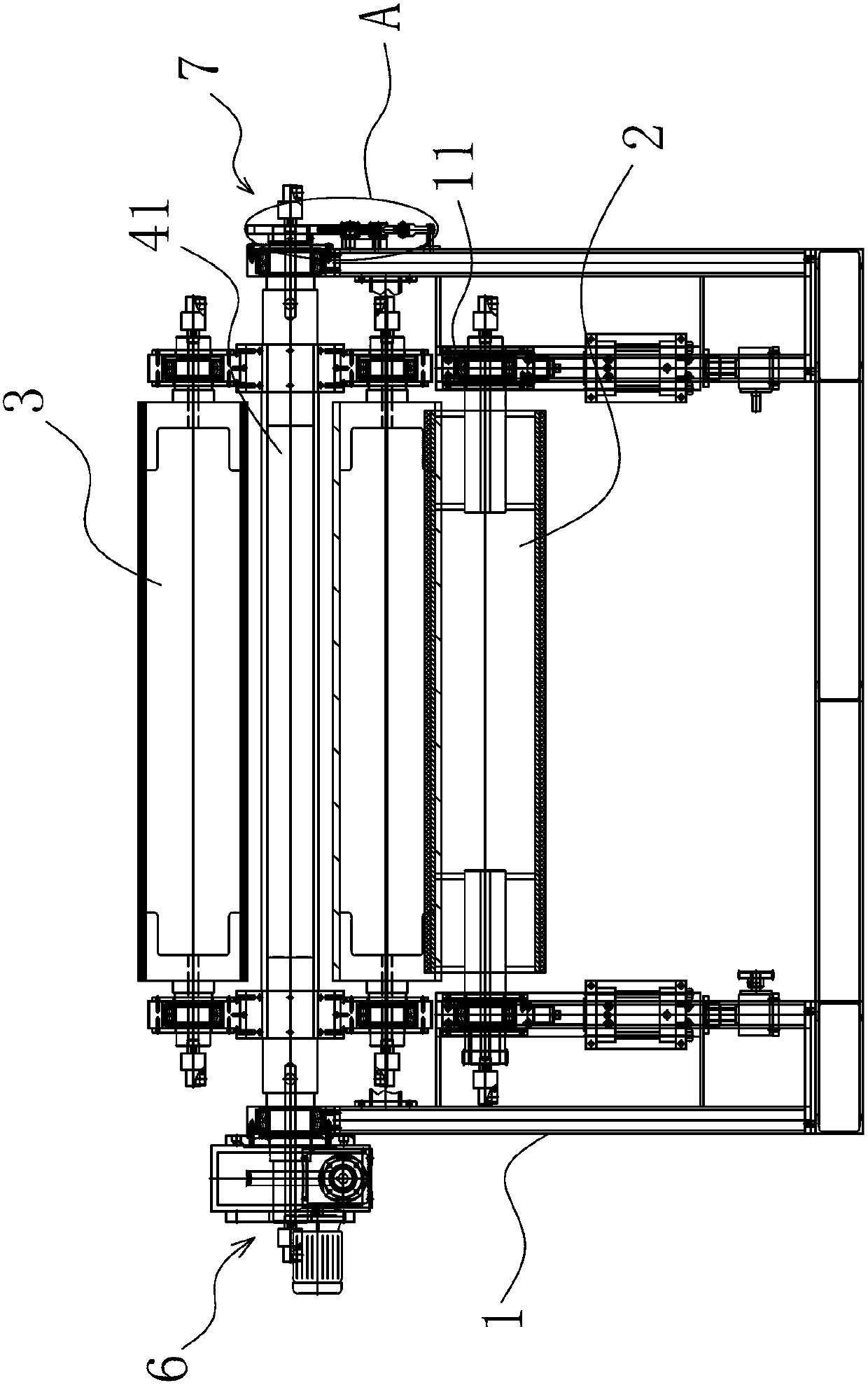

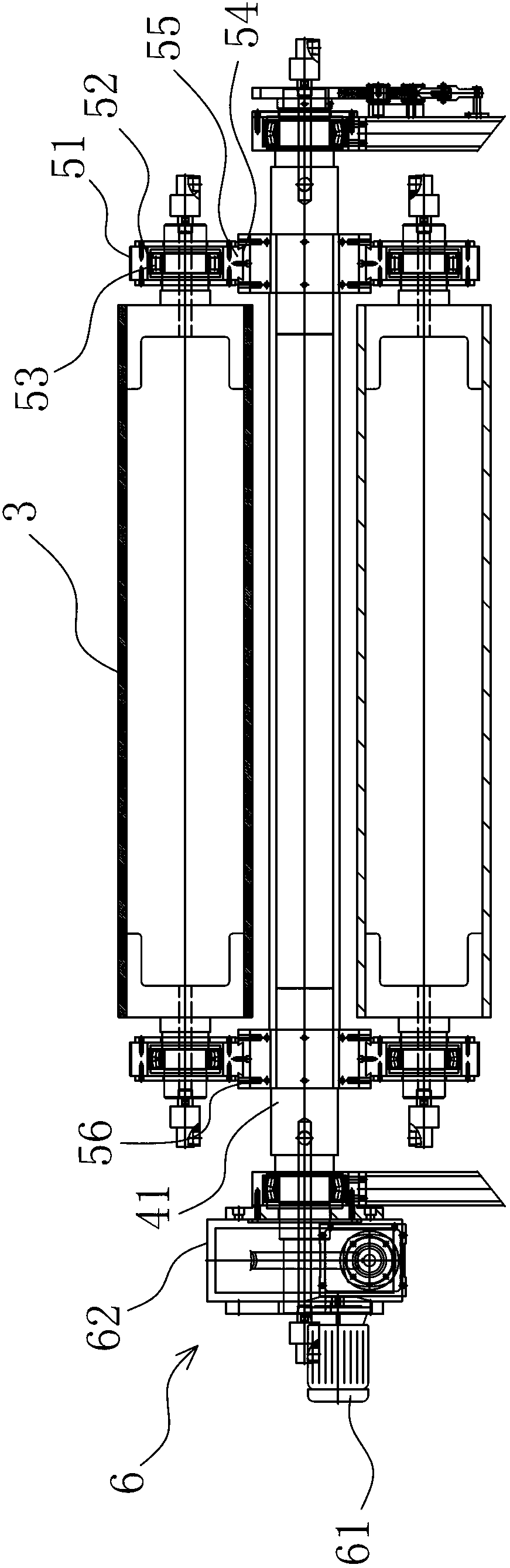

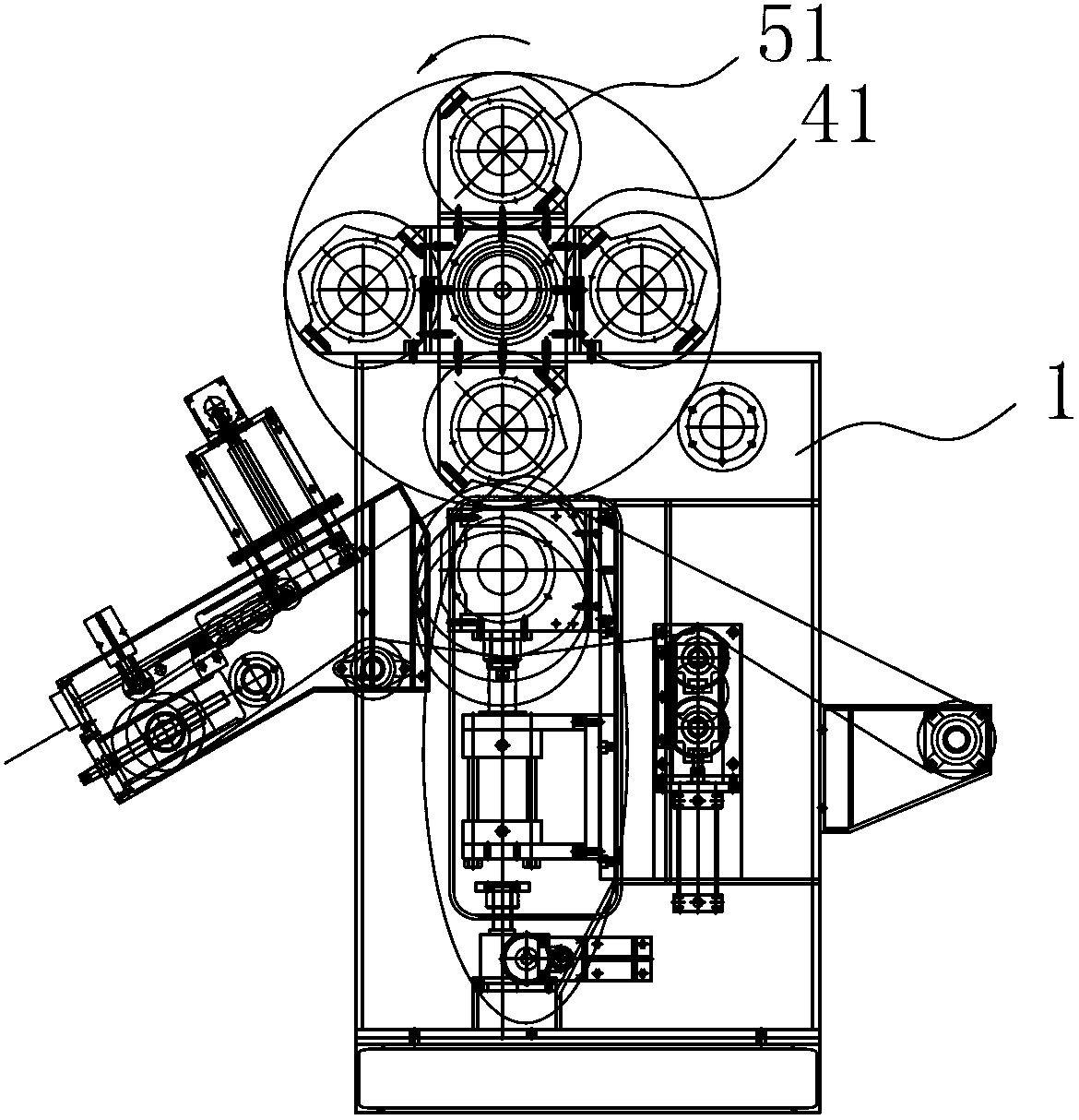

[0022] Such as Figure 1-4 As shown, the embossing device of the embossing machine includes a lower roller 2 arranged on the frame 1, and several embossing wheels 3 are arranged above the lower roller 2, and the outer surfaces of the embossing wheels 3 have different embossing patterns. The embossing wheels 3 are all connected to the transposition mechanism 4 and can cooperate with the lower roller 2 respectively under the drive of the transposition mechanism 4 .

[0023] Transposition mechanism 4 comprises the main shaft 41 that is arranged on frame 1 and can rotate, is provided with the installation structure 5 that is used to install embossing wheel 3 on main shaft 41, is installed on the installation structure 5 and is positioned at main shaft 41 periphery and main shaft 41 Embossing wheels 3 arranged in parallel. The main shaft 41 is connected with a driving mechanism 6 capable of driving the main shaft 41 to rotate, and a rotation limiting mechanism 7 capable of prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com