Integral type stainless steel seat

An integral, stainless steel technology, applied in seats, railway car body parts, transportation and packaging, etc., can solve the problems of tight installation space at fixed points, unfavorable post-maintenance, and affecting installation efficiency, etc., to achieve simple structure, convenient and fast installation, The effect of small connection gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

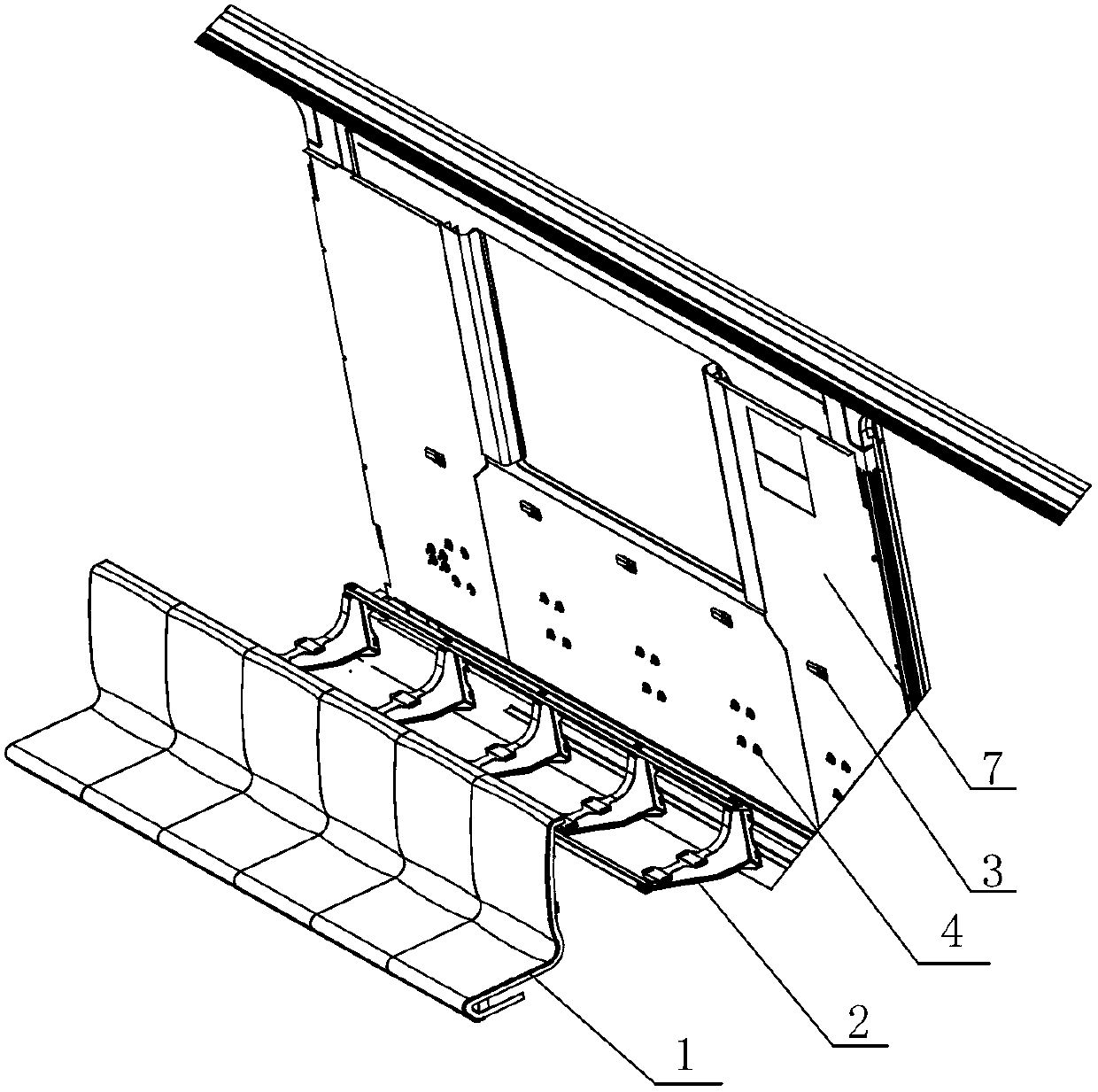

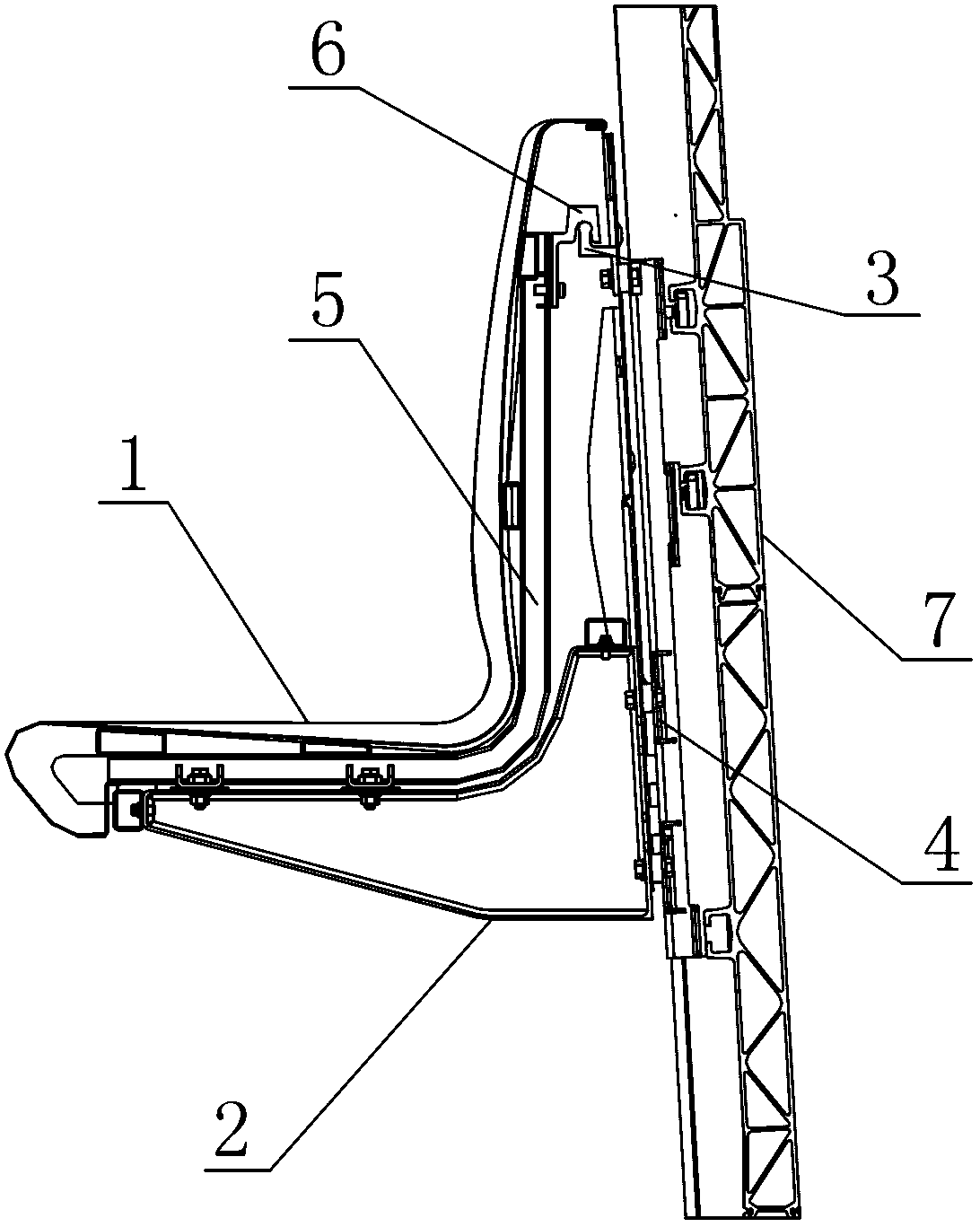

[0016] Such as Figure 1-2 Shown, be the integral stainless steel seat of the embodiment of the present invention, comprise integral seat mask 1, the seat frame 2 that is fixed with side wall 7, the rear side of seat mask 1 is fixed with mask bracket 5, and the side of mask bracket 5 The upper end has a hook 6, the side wall 7 is provided with a seat hook 3 corresponding to the hook 6, and the mask support 5 is fixedly connected with the seat frame 2 by bolts. The seat frame 2 is fixedly connected with the side wall 7 through the seat mount 4 .

[0017] Such as figure 2 As shown, the lower end surface of the mask bracket 5 is fixedly connected with the upper end surface of the seat frame 2 by bolts, and the inner side surface of the lower end of the seat mask 1 is fixedly connected with the front end surface of the seat frame 2 by bolts.

[0018] The mask bracket 5 of the present embodiment has two crossbeams, and support beams are connected and spaced between the crossbeam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com