Plastic film suction nozzle

A plastic film and vacuum technology, used in thin material processing, object supply, pile separation, etc., can solve the problem that the plastic film suction nozzle fails to meet the requirements of automatic operation, prevent wrinkling, meet automation, and prevent air leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation method of the present invention will be further described below in conjunction with the accompanying drawings.

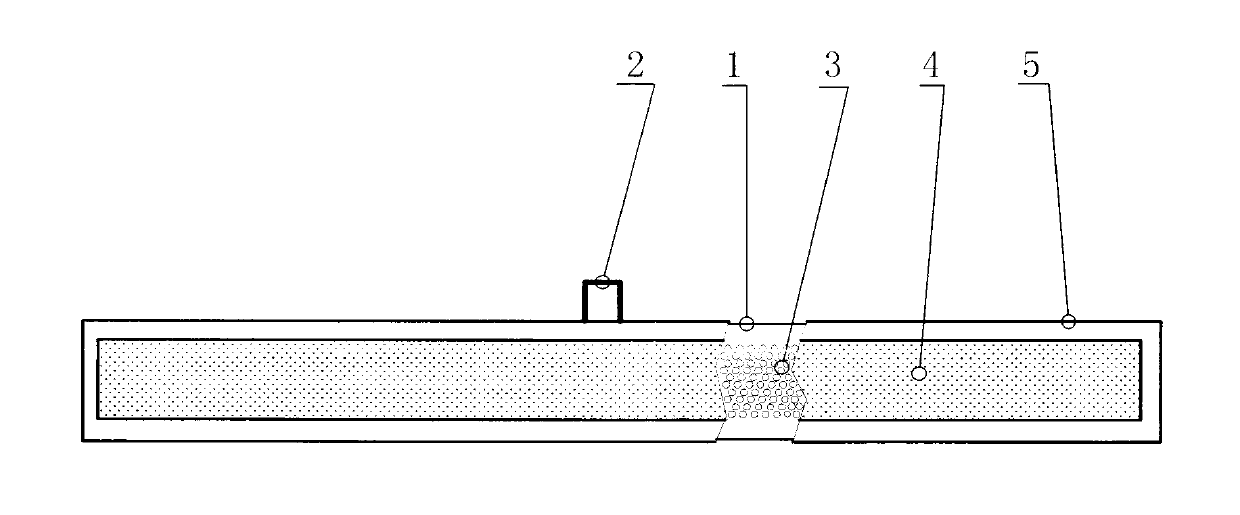

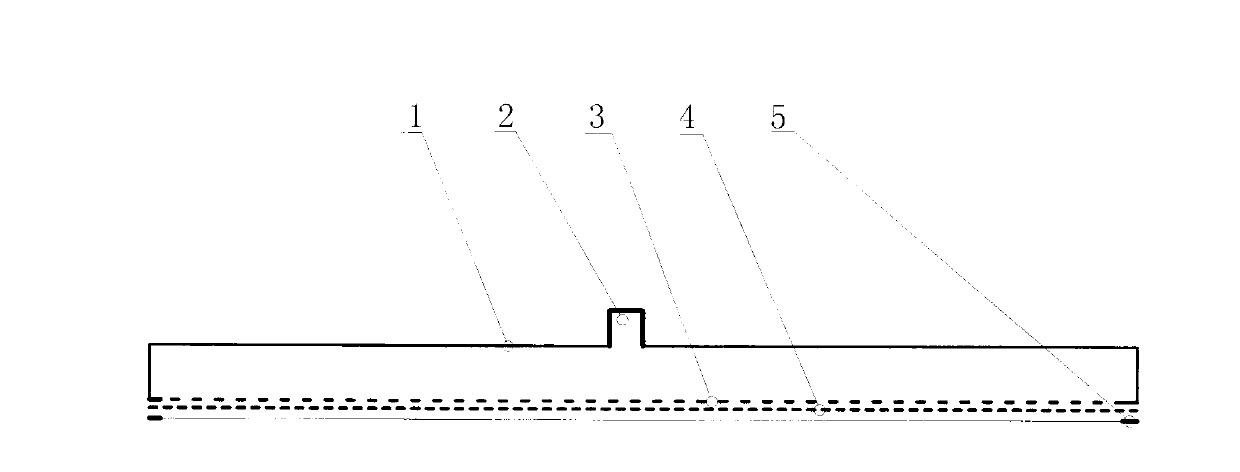

[0014] figure 1 , figure 2 , including vacuum connecting pipe 1, vacuum chamber 2, air-permeable surface 3, microporous plate 4, sealing skin 5, etc.

[0015] The invention is a plastic film suction nozzle, which comprises a vacuum connecting pipe 1, a vacuum chamber 2, an air-permeable surface 3, a microporous plate 4, a sealing skin 5 and the like.

[0016] The plastic film suction nozzle is arranged in an up and down structure, the upper end is provided with a vacuum connecting pipe 1, a vacuum chamber 2 is arranged under the vacuum connecting pipe 1, a ventilating surface 3 is arranged on the lower end surface of the vacuum chamber 2, and micropores are arranged on the lower end surface of the ventilating surface 3 plate 4 and sealing skin 5 , the microporous plate 4 is connected to the air-permeable surface 3 , and the seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com