Concrete piston automatic returning device in closed type pumping system

The technology of a concrete piston and a closed pump, which is applied in the field of automatic piston return device, can solve the problems that the concrete piston 8 cannot be taken out and the difficulty of replacing the concrete piston 8 is increased, and achieves the advantages of avoiding the difficulty of replacement, saving power, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

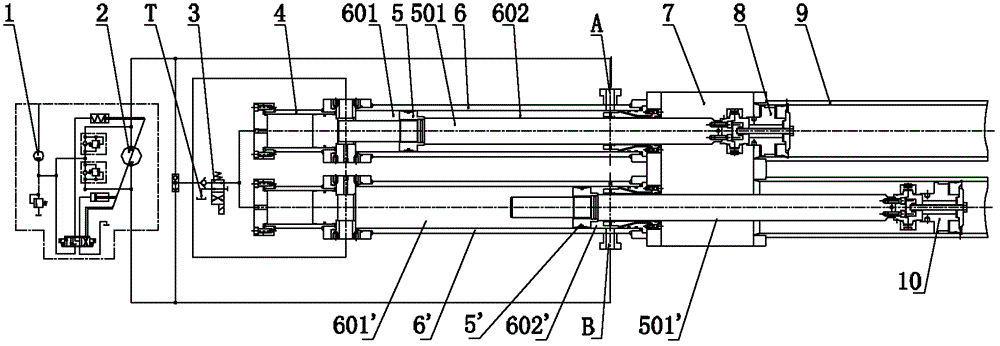

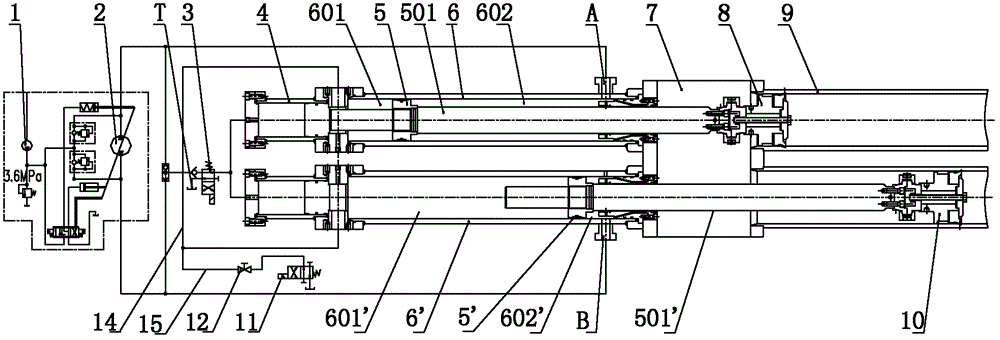

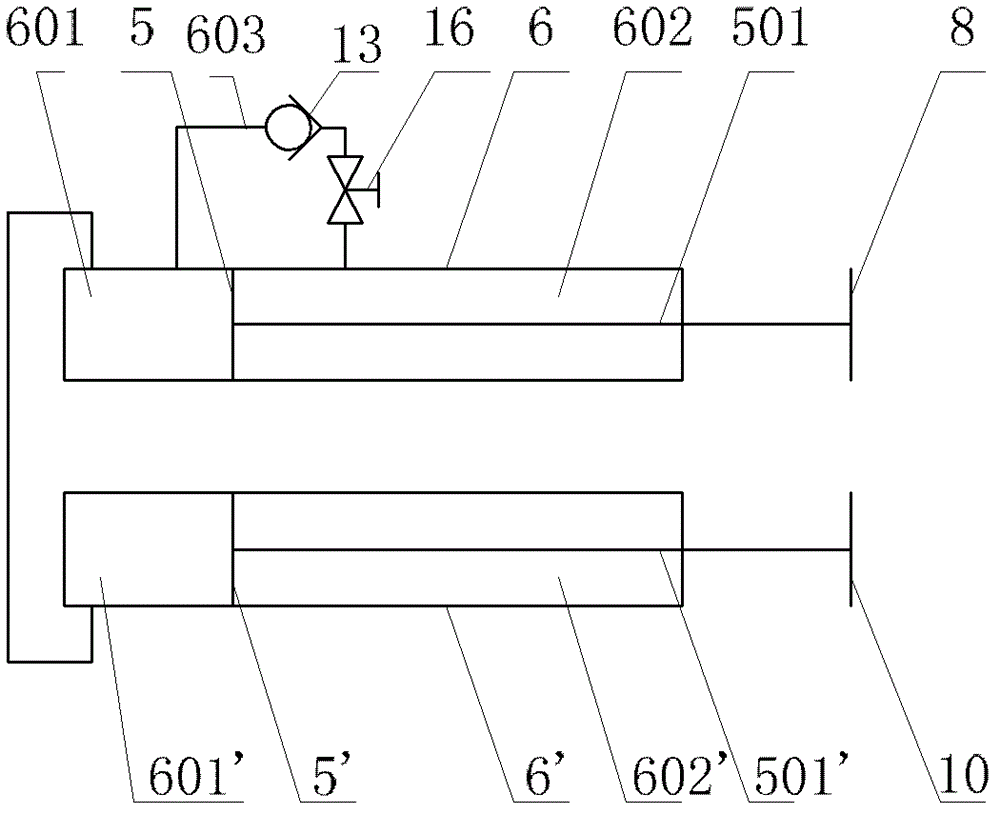

[0028] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0029] The present invention considers that when the closed pumping system is not pumping, there is always a preset inherent pressure (such as 3MPa, etc.) The power of the piston can realize the automatic retraction of the concrete piston linked with the piston of the main oil cylinder, and this conversion can be realized by releasing the oil pressure in the rodless chamber. The present invention connects the rodless cavity with the oil tank, at this moment, the oil pressure difference between the rod cavity and the rodless cavity can push the main oil cylinder piston to move in the direction of the rodless cavity, and the hydraulic oil in the rodless cavity will be squeezed Press it into the oil tank, which drives the retraction of the concrete piston. When the main oil cylinder piston stops moving, the concrete pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com