Vacuum pump

A technology of vacuum pumps and outer wheels, which is applied in the direction of pumps, pump components, axial flow pumps, etc., can solve the problems of complex structure, easy damage, easy tilting of the rotating shaft, and vibration control effects, so as to improve vibration control performance and suppress structural changes. complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

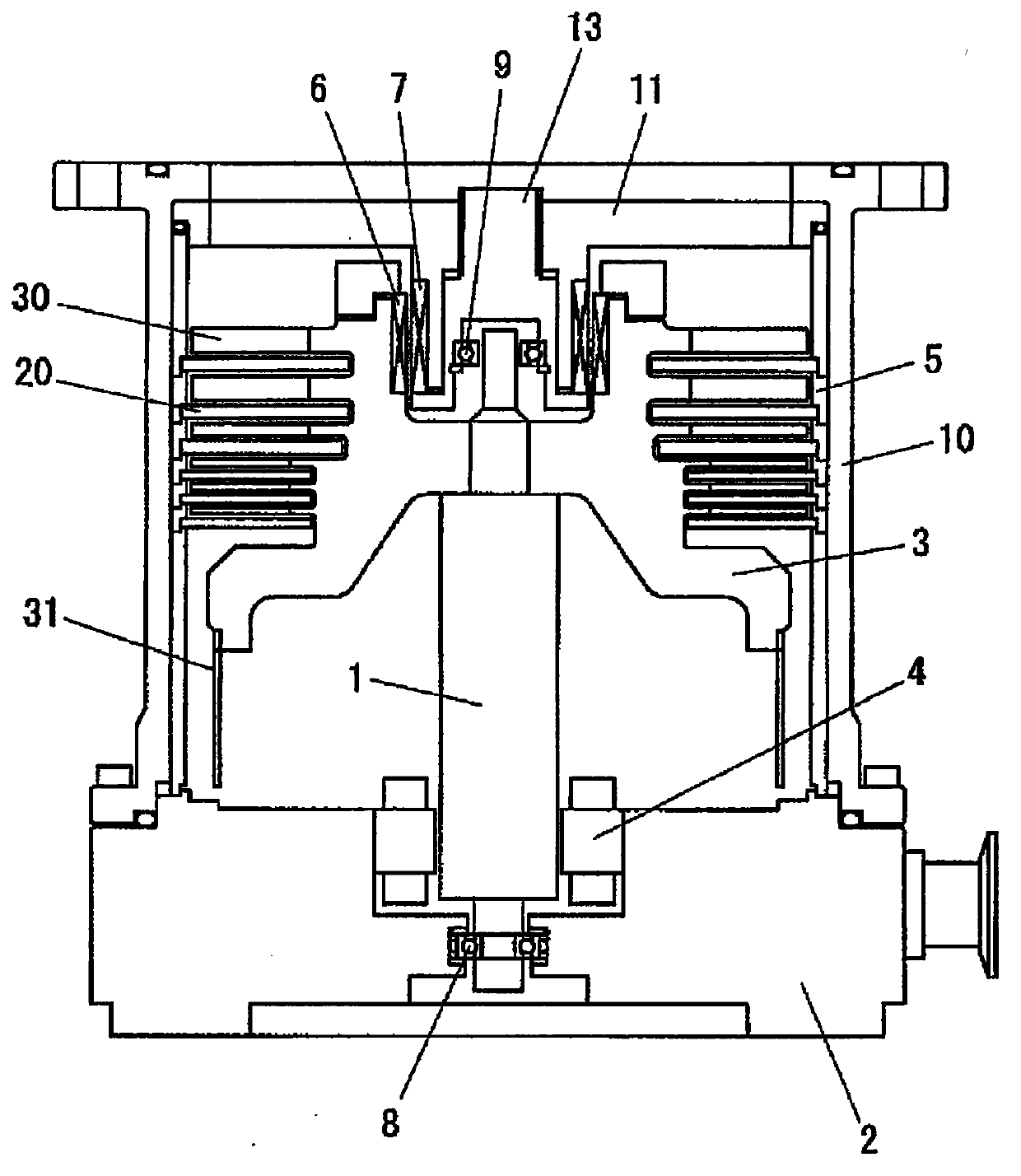

[0039] Hereinafter, embodiments for implementing the present invention will be described with reference to the drawings. figure 1 It is a figure which shows one embodiment of the vacuum pump of this invention, and is a cross-sectional view of a turbomolecular pump. Rotary vanes 30 and a cylindrical portion 31 are formed in the rotor 3 as exhaust function portions. The fixed fins 20 are provided corresponding to the rotary fins 30 . In addition, a fixed cylinder as a fixed side exhaust function part is provided corresponding to the cylindrical part 31, but in figure 1 Illustrations are omitted.

[0040] The rotor 3 is fastened on the shaft 1 and the shaft 1 is driven in rotation by the electric motor 4 . The rotor 3 fastened to the shaft 1 is rotatably supported by using a magnetic bearing having permanent magnets 6 and 7 and a ball bearing 8 . For the ball bearing 8, for example, an angular contact ball bearing is used. A cylindrical permanent magnet 6 is fixed on the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com