Screw unit and lifting device utilizing screw unit

A lifting device, screw technology, applied in the direction of transmission, transportation and packaging, elevators in buildings, etc., can solve the problems of wire rope or chain breakage, dangerous safety, poor safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings:

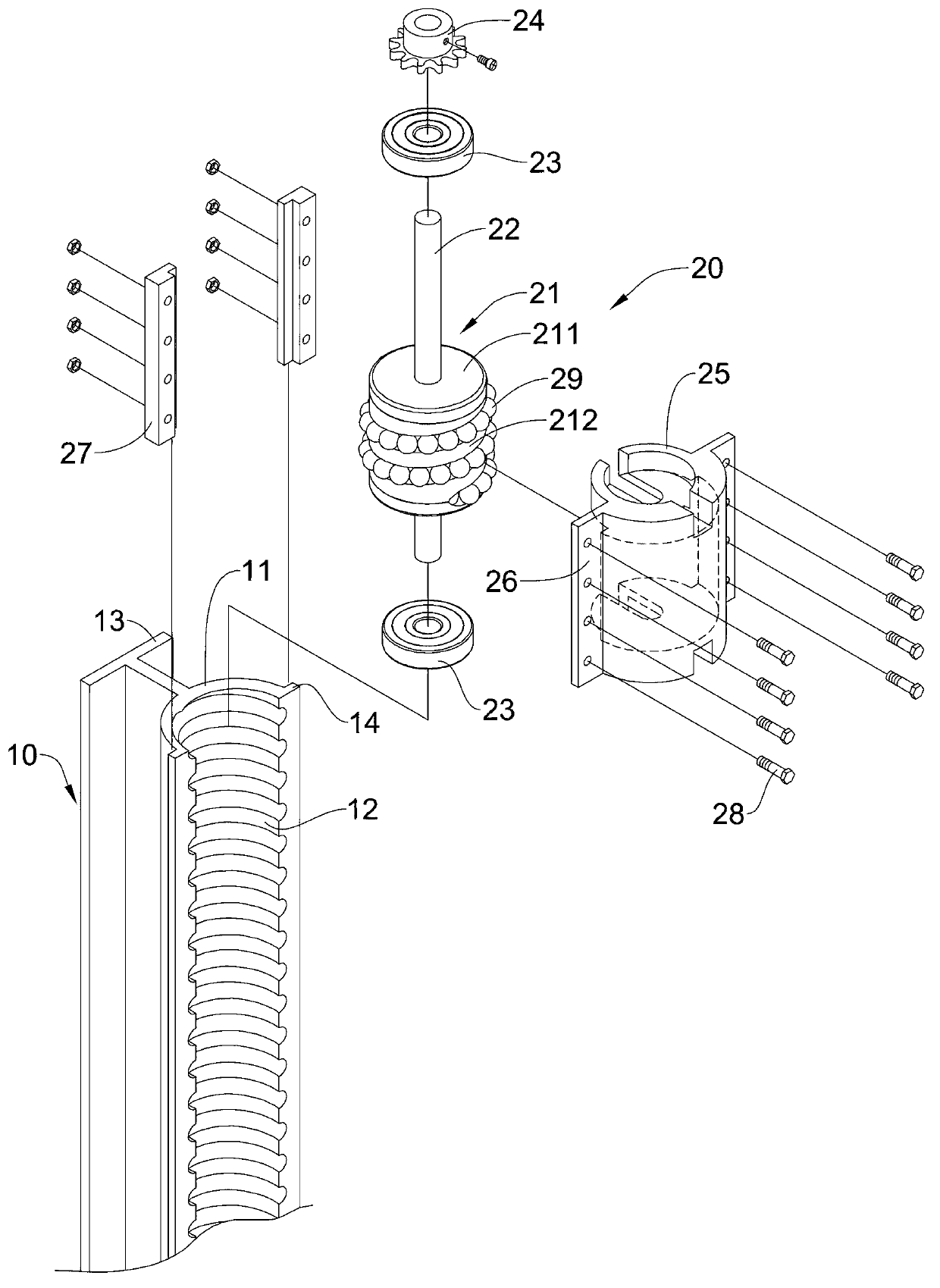

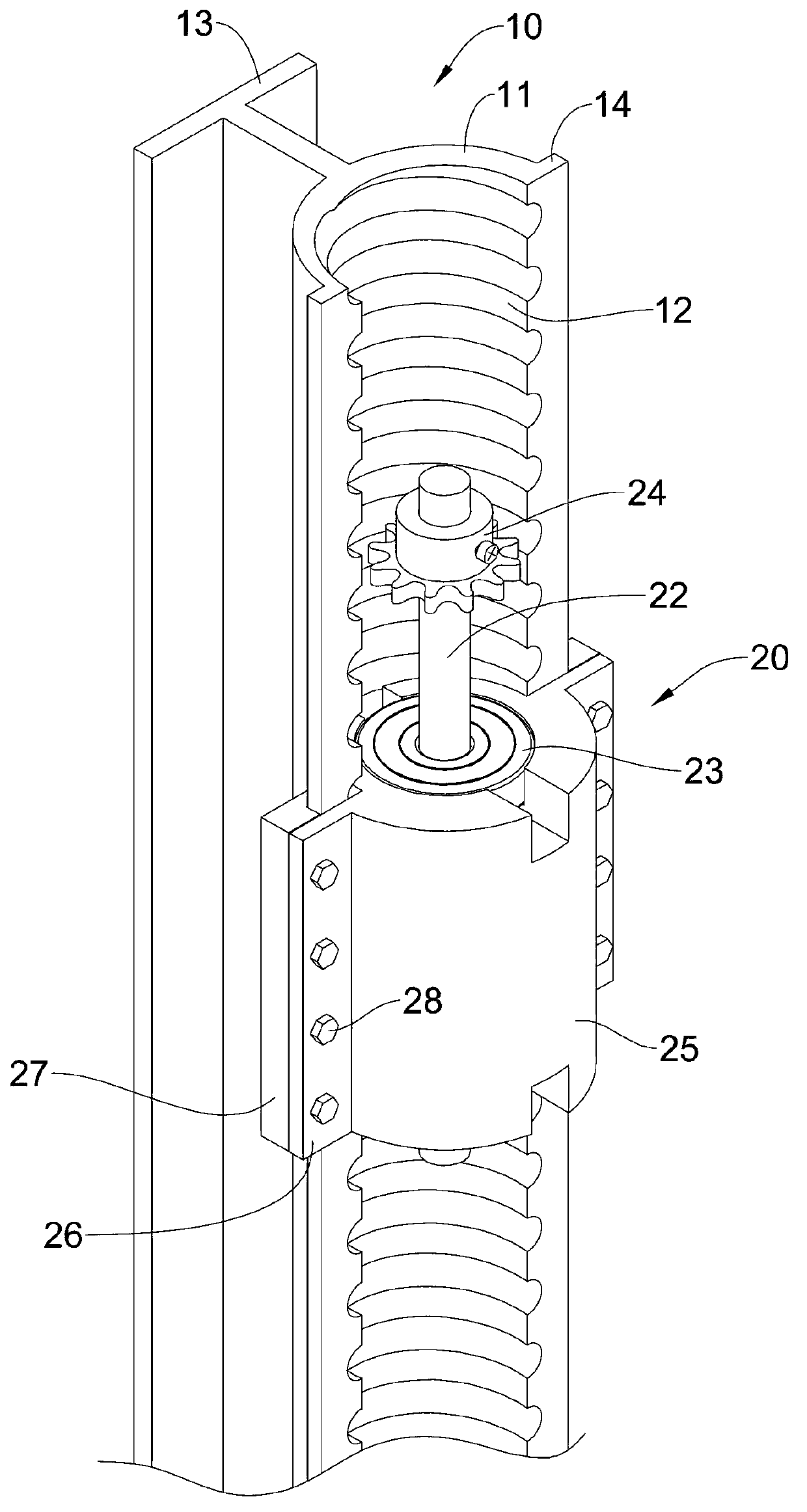

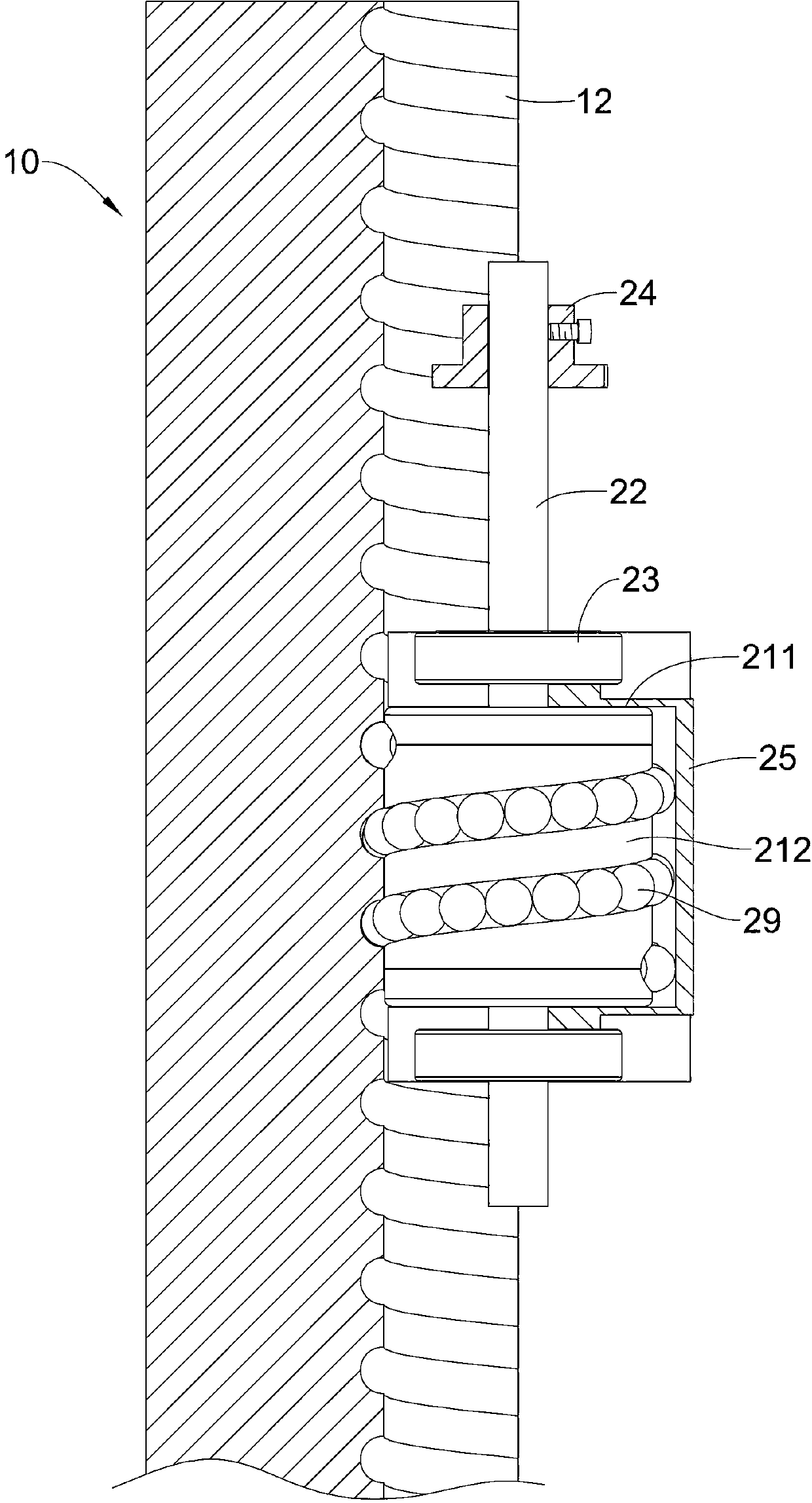

[0039] See Figure 1 to Figure 3 , Is a specific embodiment of the screw unit of the present invention. The screw unit 10 includes a body 11 with a moving groove and an axial opening formed on the body 11 to form an open body 11 and the groove surface of the moving groove The disc is provided with an internal thread 12, and an assembly socket 13 is provided on the outer surface of the main body 11, wherein the assembly socket 13 is a T-shaped component, and the assembly socket 13 can take different forms according to requirements.

[0040] In the above, the screw unit 10 can be provided with a rotating assembly 20. The rotating assembly 20 is arranged in the moving groove of the screw unit 10 and can move axially relative to the main body 11. The rotating assembly 20 includes a rotating shaft. The rotating unit 21 of 22 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com