Loading device and method for car body strength test bed end wall

A technology of strength test and loading device, applied in the field of rail transit, can solve the problems such as the simulation state that cannot satisfy the simultaneous application of loads on the walls at both ends of the car body, etc., and achieves the effects of flexible adjustment, improved accuracy and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

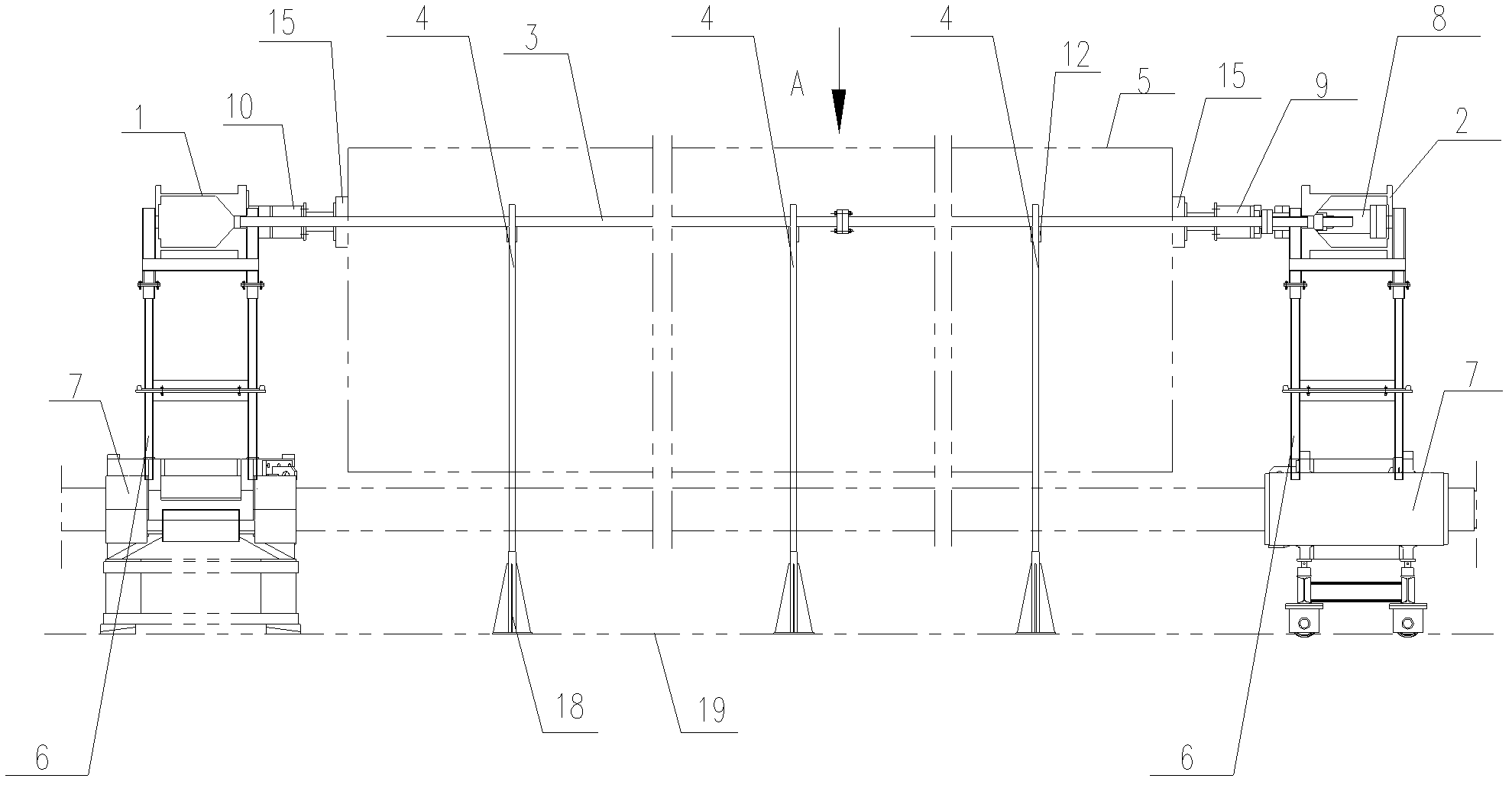

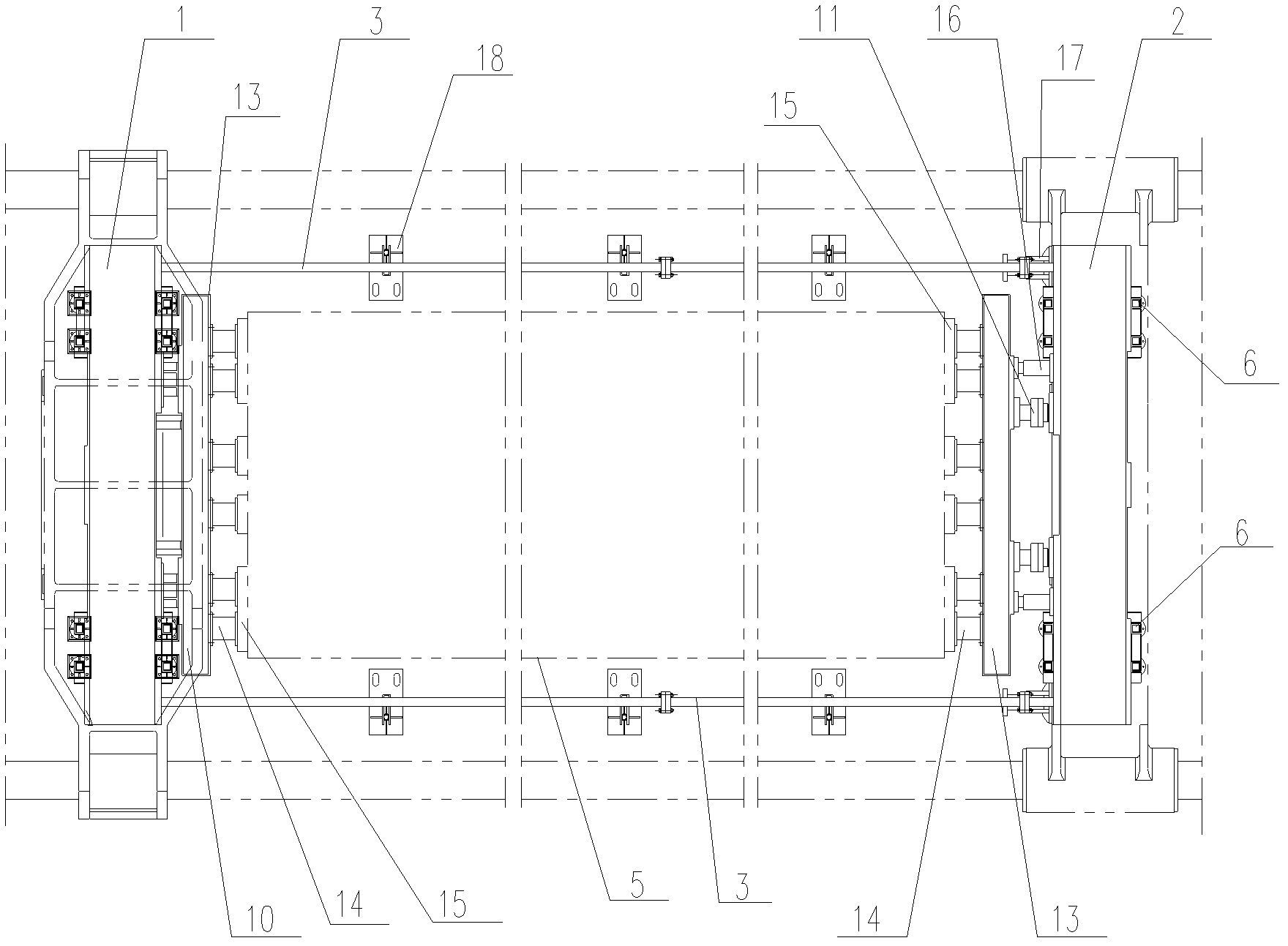

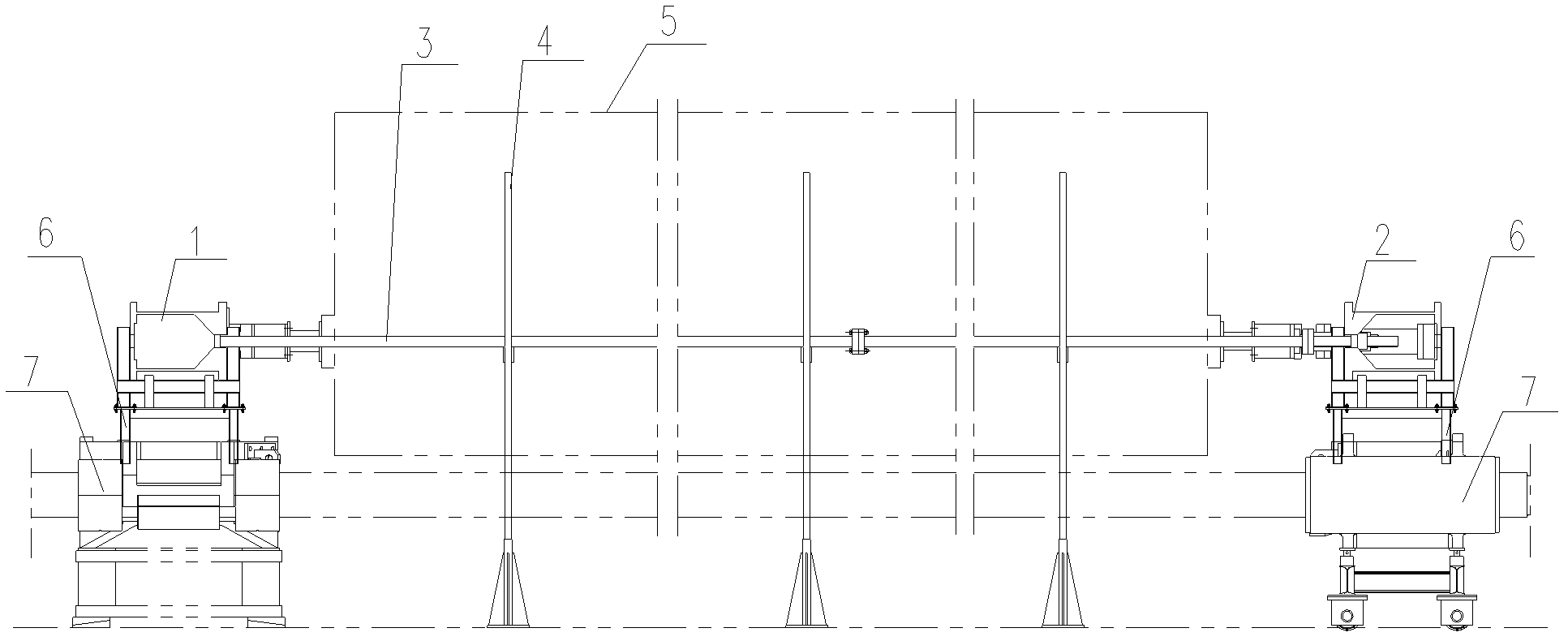

[0044] Example 1, such as figure 1 and figure 2 As shown, the end wall loading device of the vehicle body strength test bench mainly includes end wall beam 1, end wall loading beam 2, longitudinal tie rod 3, support column 4, bracket 6, beam mounting seat 7, loading oil cylinder 8, the first A transfer device 9 and a second transfer device 10 .

[0045] Among them, a rectangular frame is composed of the end wall beam 1, the end wall loading beam 2, the longitudinal tie rod 3 and the support column 4, and the test vehicle body 5 is placed in the rectangular frame. The end wall beam 1 and the end wall loading beam 2 are located on both sides of the tested vehicle body 5 close to the end wall. There are two longitudinal tie rods 3. Fixedly connected, each longitudinal tie rod 3 is fixedly connected with a plurality of support columns 4, in this embodiment, each longitudinal tie rod 3 is fixedly connected with three support columns 4, and the support columns 4 play a supporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com