Period reciprocating magnetic edgy current shaft coupling

A magnetic eddy current and coupling technology, applied in the direction of asynchronous inductive clutch/brake, etc., can solve the problems of difficult to apply load, consume a lot of manpower, waste of manpower, etc., achieve stable and reliable performance, simple structure, save energy and manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the accompanying drawings.

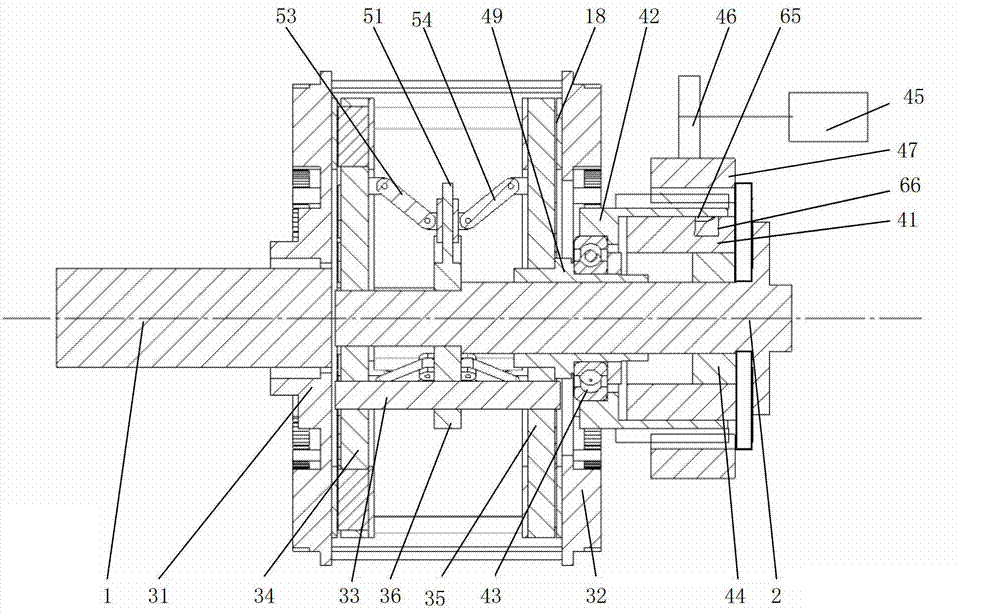

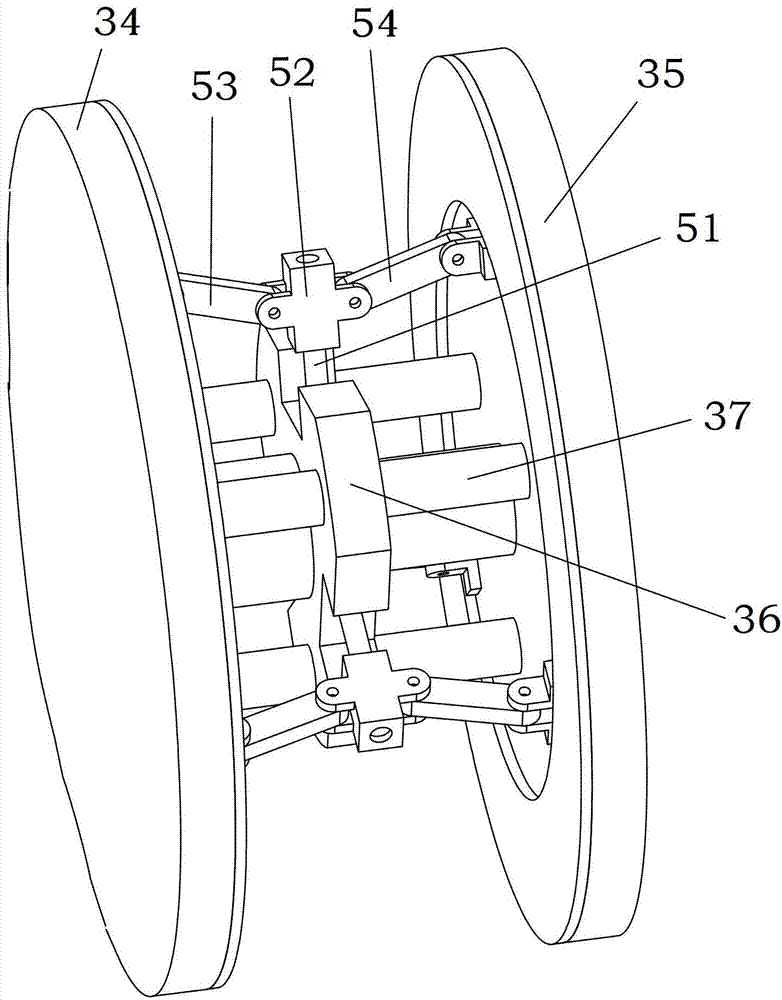

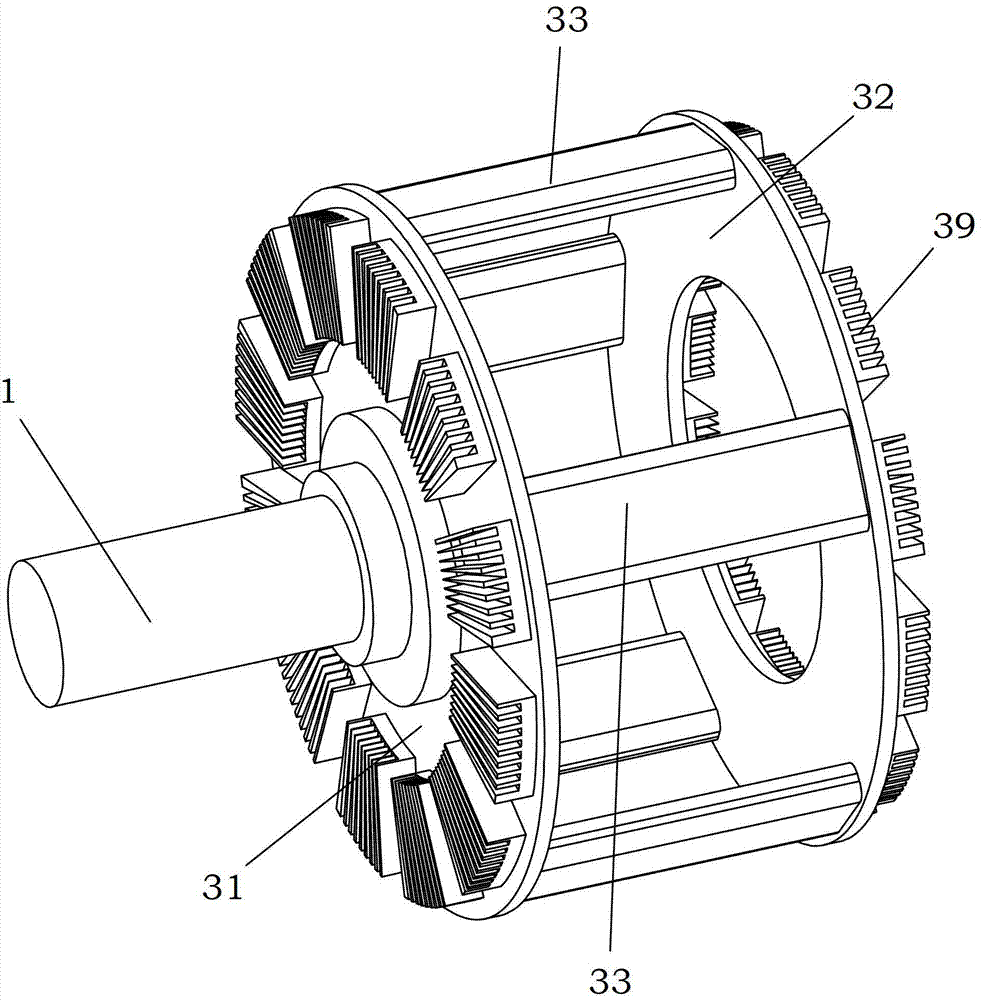

[0027] refer to Figure 1-5: Periodic reciprocating magnetic eddy current coupling, comprising an input shaft 1 connected to the first motor and an output shaft 2 connected to the load, the input shaft 1 is fixedly fitted with a left conductor disc 31, the magnetic eddy current coupling It also includes a right conductor disk 32 arranged in parallel with the left conductor disk 31, and the right conductor disk 32 rotates synchronously with the left conductor disk 31 through a connector 33. In this embodiment, the connector 33 is a plurality of steel plates, and the left conductor disk 31, A cage structure is formed between the steel plate and the right conductor disk 32, a left disk 34 and a right disk 35 are arranged between the left conductor disk 31 and the right conductor disk 32, and an output shaft is arranged between the left disk 34 and the right disk 35. 2 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com