Method for manufacturing bread containing dried fruit

A technology for dried fruit and bread, applied in the field of bread containing dried fruit and producing bread containing dried fruit, can solve the problems of loss of soft texture of bread, stale bread and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and Embodiment 2

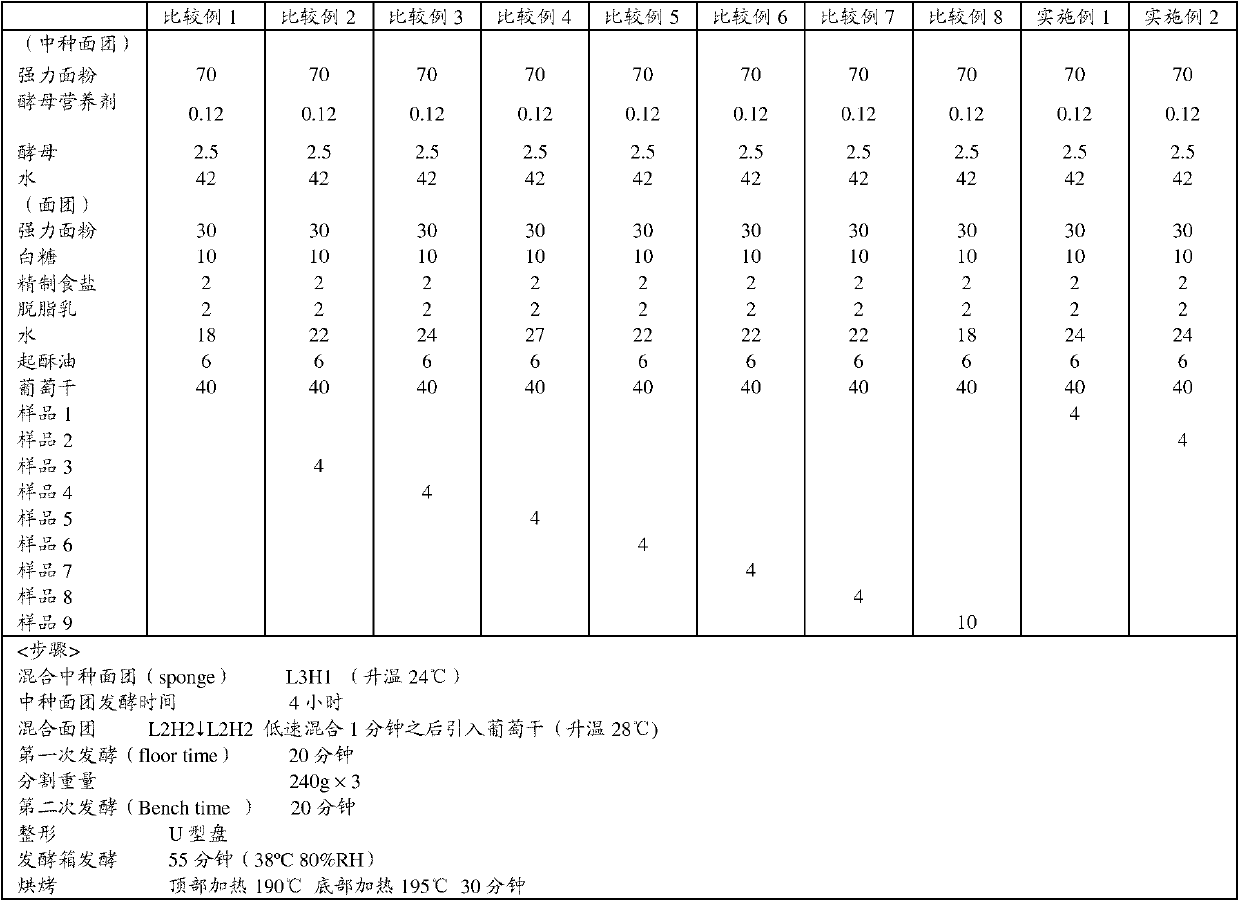

[0032] Example 1 and Example 2; Comparative Examples 1-8

[0033] The bread containing raisins was prepared according to the mixtures and procedures described in Table 2. Specifically, the maximum amount of water added was changed according to the added gelatinous starch and gelatinous hydroxypropyl starch, and the test was performed using the amount of water considered to be the optimal amount. The values shown in Table 2 are given in Baker's %.

[0034] Table 2

[0035]

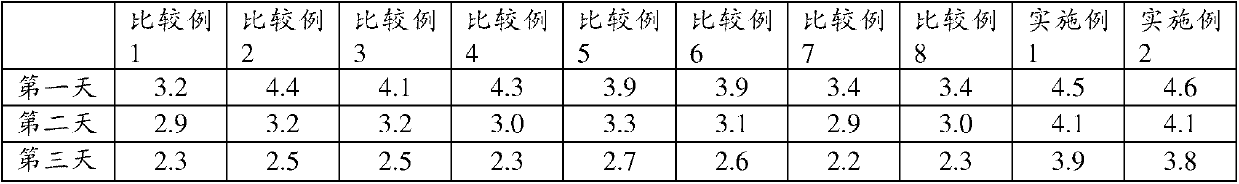

[0036] After the first, second, and third days of production, each of these breads was tasted by 10 people, and softness (non-staling) was evaluated on a 5-point scale. Table 3 shows their average scores.

[0037] The evaluation criteria used in the above 5-point evaluation test are as follows:

[0038] 5 points: very soft and moist

[0039] 4 points: soft and moist

[0040] 3 points: standard texture

[0041] 2 points: slightly dry feeling

[0042] 1 point: dry and hard

[0043] 0 points: no product value

[0044] t...

Embodiment 3 and 4

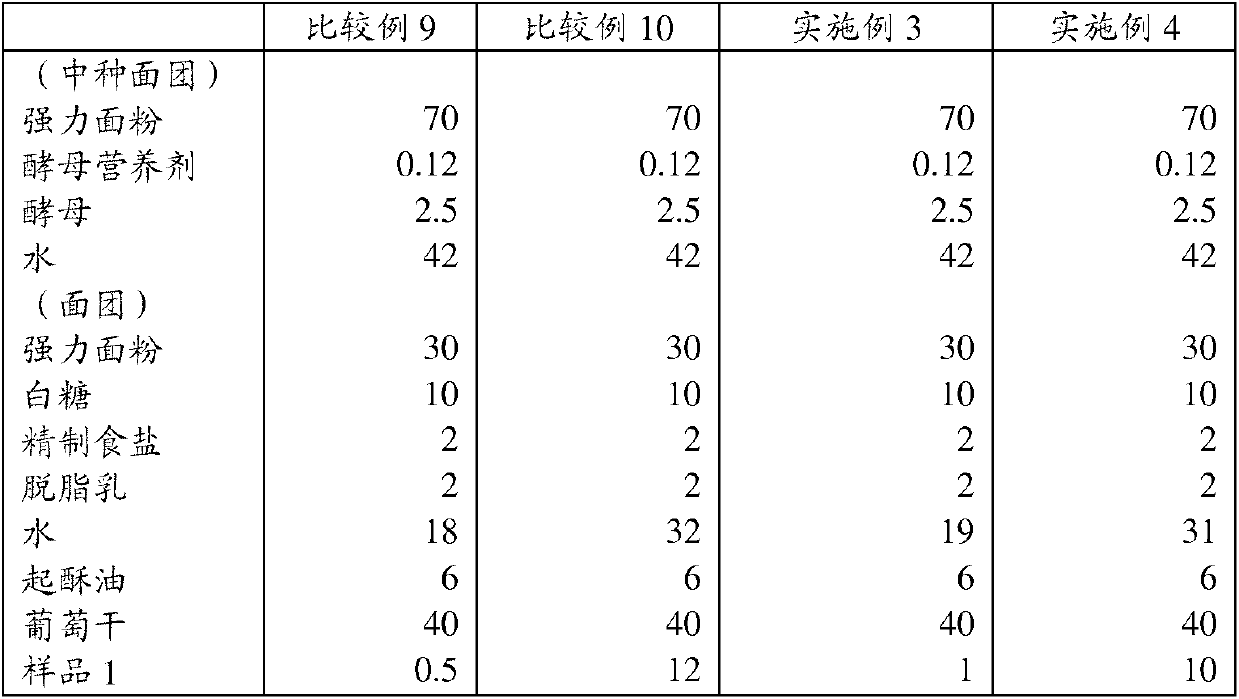

[0047] Examples 3 and 4; Comparative Examples 9 and 10

[0048] The raisin-containing bread was prepared according to the mixture and procedure described in Table 4. Specifically, the maximum amount of water added was changed according to the added colloidal hydroxypropyl starch, and the test was performed using the amount of water considered to be the optimal amount. The values shown in Table 4 are given in Baker's %.

[0049] Table 4

[0050]

[0051]

[0052] After the first day, the second day, and the third day, each of these breads was tasted by 10 people, and the softness (freshness) was evaluated on a 5-point scale. Table 5 shows their average scores. The evaluation standard of the highest 5-point evaluation test is the same as the evaluation standard used in the foregoing embodiment. Please note that the bread of Comparative Example 10 could not be tasted due to poor processability and insufficient volume.

[0053] table 5

[0054]

[0055] Although the first day e...

Embodiment 5 and 6

[0056] Examples 5 and 6; Comparative Example 11

[0057] The raisin-containing bread was prepared according to the mixture and procedure described in Table 6. Specifically, the maximum amount of water added was changed according to the added gelatinous starch, and the test was performed using the amount of water considered to be the optimal amount. The values shown in Table 6 are given in Baker's %.

[0058] Table 6

[0059]

[0060]

[0061] After the first day, the second day, and the third day, each of these breads was tasted by 10 people, and the softness (freshness) was evaluated on a 5-point scale. Table 7 shows their average scores. Specifically, the evaluation standard of the highest 5-point evaluation test is the same as the evaluation standard used in the foregoing embodiment.

[0062] Table 7

[0063]

[0064] Although these results obtained in Processability Example 5, Processability Example 6 and Comparative Example 11 are similar to those obtained for plain br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com