Jet type glue supply head

A technology of injection point and glue head, which is applied in the direction of coating and liquid coating device on the surface, can solve the problems of low displacement magnification of the amplification mechanism, change of colloid viscosity, and limitation of dispensing efficiency, so as to overcome the impact of firing pin and Nozzle distance control is difficult, high resonance operating frequency, and the effect of overcoming the inconvenience of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

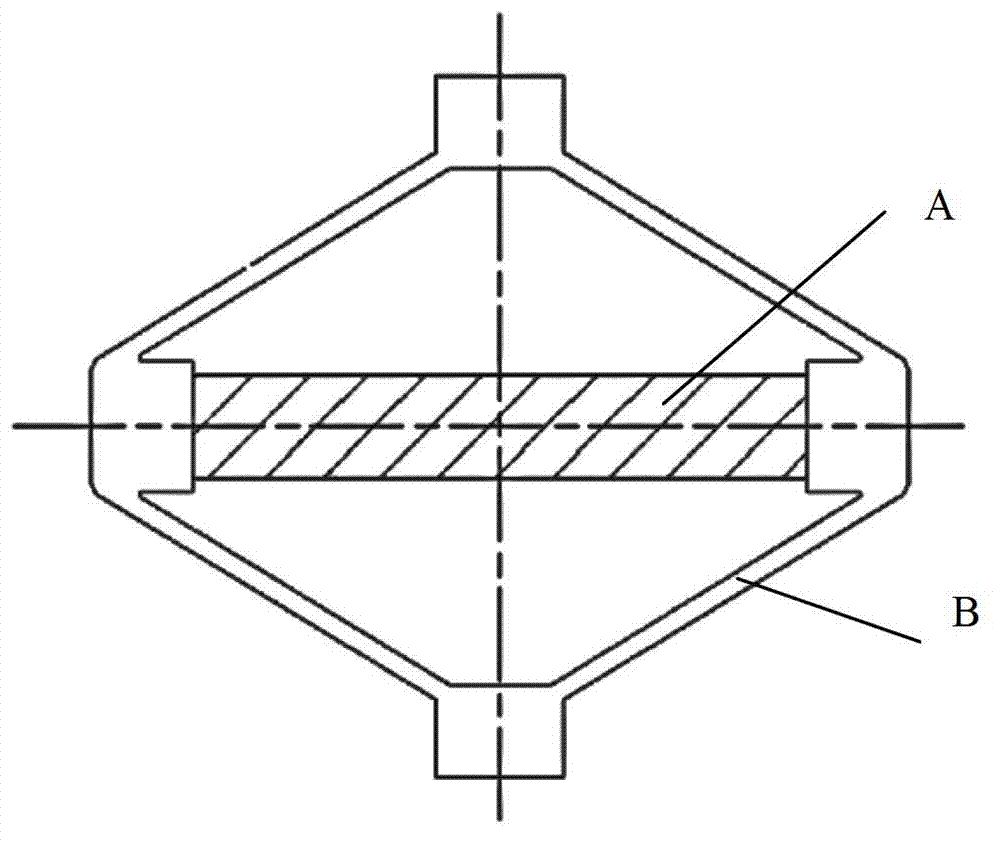

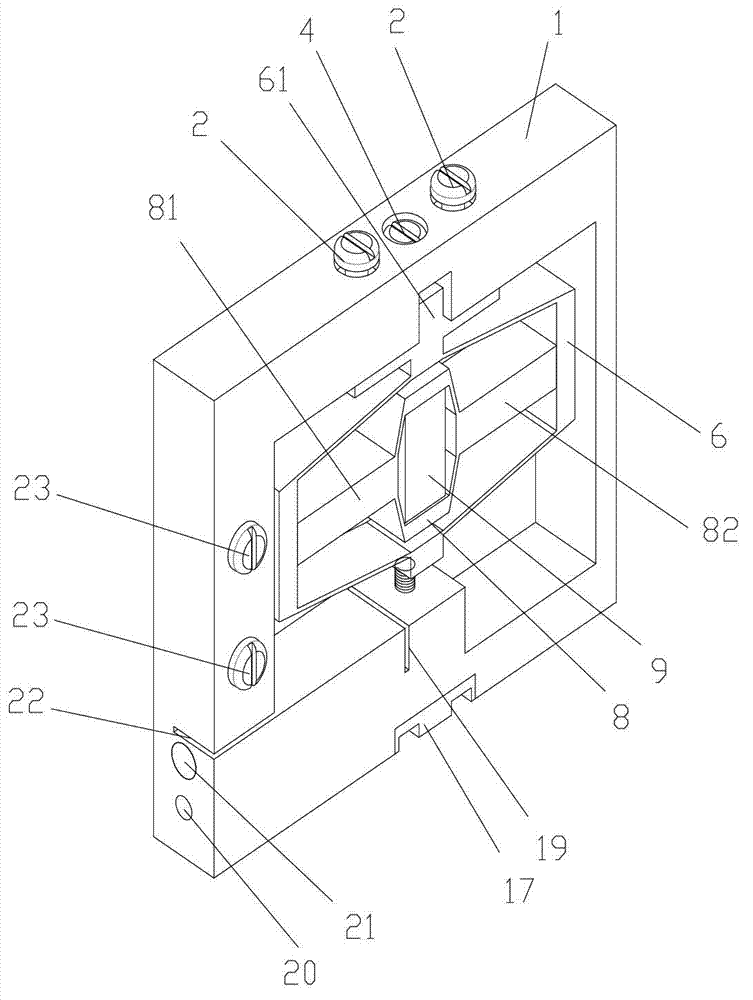

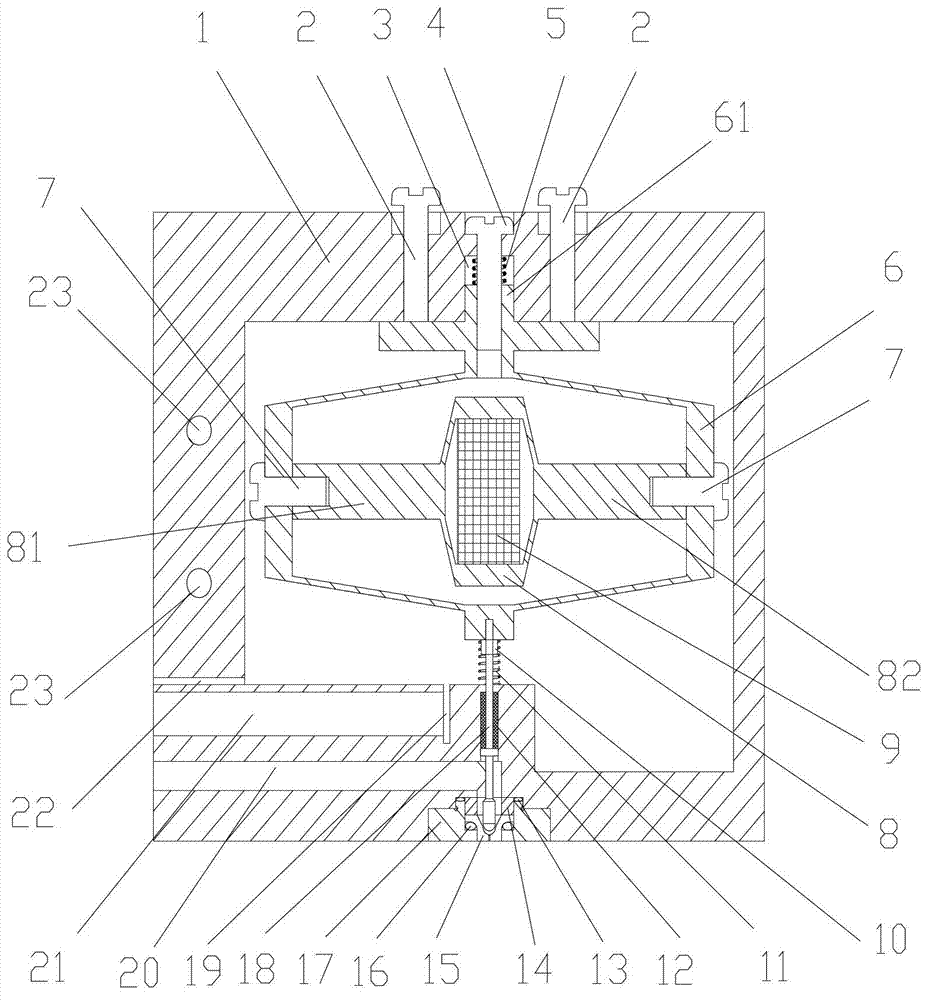

[0020] see figure 2 and 3 , The embodiment of the present invention includes a base 1, a heating block 21, a primary displacement amplifying mechanism, a secondary displacement amplifying mechanism, a striker 18, a striker return spring 11, a nozzle 15, a nozzle seat 17, and the like.

[0021] The base 1 is a planar rectangular frame, and the base 1 is provided with a colloid flow channel 20 . The heating block 21 is arranged in the base 1, and the heating block 21 is used to heat and adjust the temperature of the colloid flowing through the colloid channel 20 to the nozzle 15, so as to change the viscosity of the colloid, so as to be suitable for colloid injection with higher viscosity. The primary displacement amplification mechanism is provided with a planar inner diamond frame 8, a piezoelectric ceramic block 9, a left stretch arm 81 and a right stretch arm 82, and the left stretch arm 81, the right stretch arm 82 and the planar inner rhombus frame 8 The left and right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com