Steel cage rolling welding traction device

A traction device, reinforcement cage technology, used in welding equipment, resistance welding equipment, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical scheme of the present invention is further described below in conjunction with embodiment and accompanying drawing, but not as its limitation:

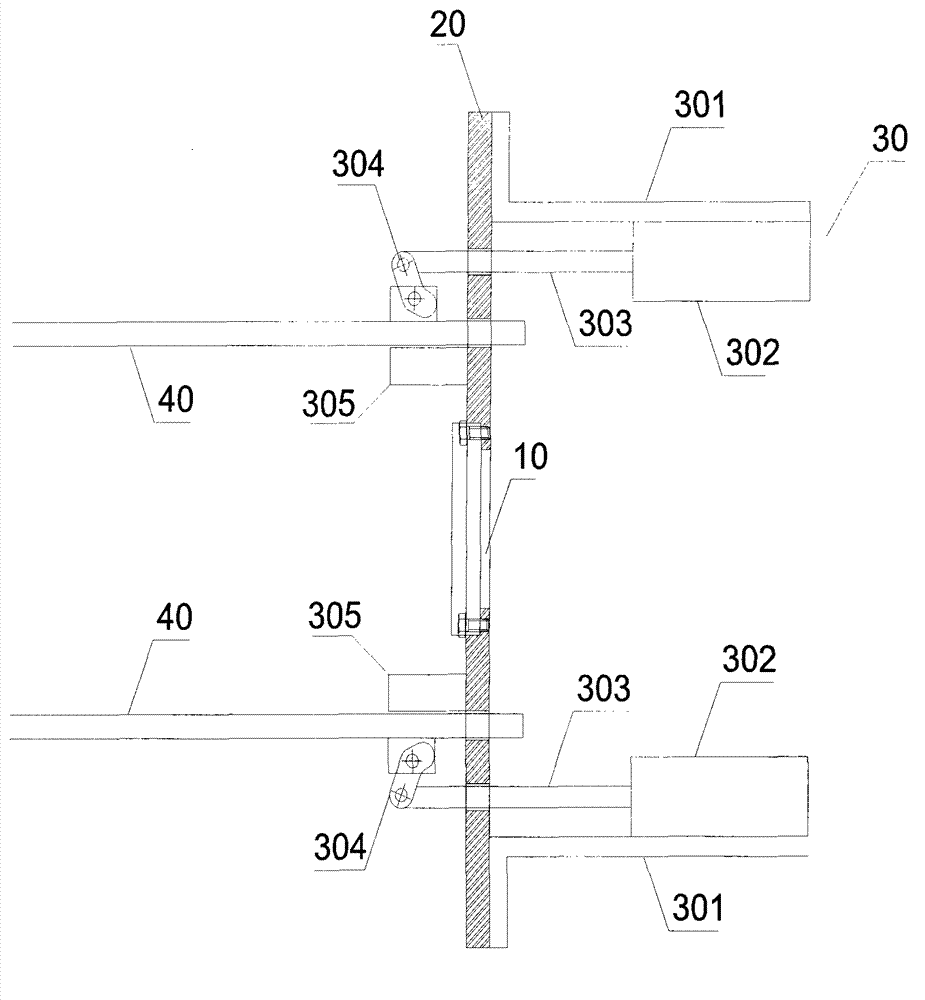

[0020] Such as figure 1 As shown, the traction device for steel cage roll welding provided by the present invention includes a traction trolley, a traction main shaft 10, a traction plate 20, and a locking assembly 30, wherein:

[0021] The traction trolley is connected with the traction main shaft 10;

[0022] The traction plate 20 is fixed on both ends of the traction main shaft 10 through fixing elements;

[0023] The locking assembly 30 includes a cylinder bracket 301, a locking cylinder 302, a cylinder rod 303, an eccentric wheel 304, and a locking support 305, and the cylinder support 301 and the locking support 302 are respectively fixed on both sides of the traction plate 20. , the locking support 302 is provided with a groove; the locking cylinder 302 is fixed on the cylinder bracket 301, one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com