Conical pipe stitch welding pressing device

A compression device and tapered tube technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of not being able to adapt to the slight angle changes on the surface of the tapered tube, and achieve the effect of reducing processing difficulty and improving production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

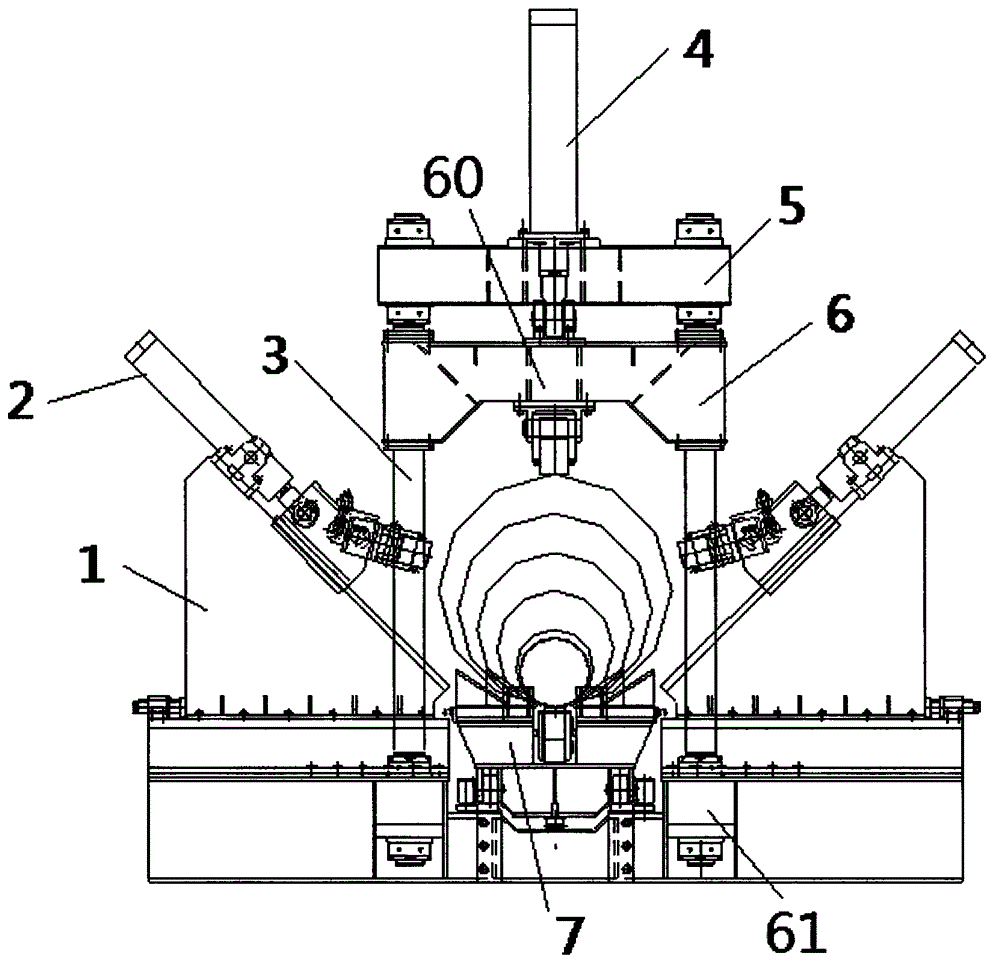

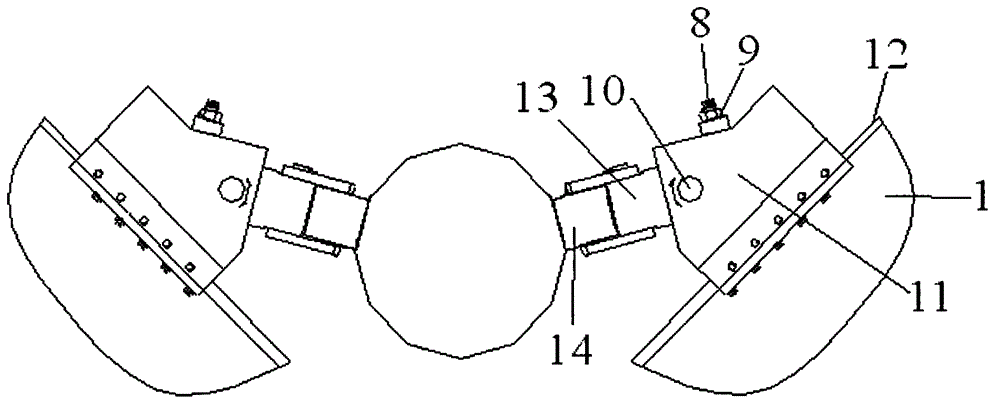

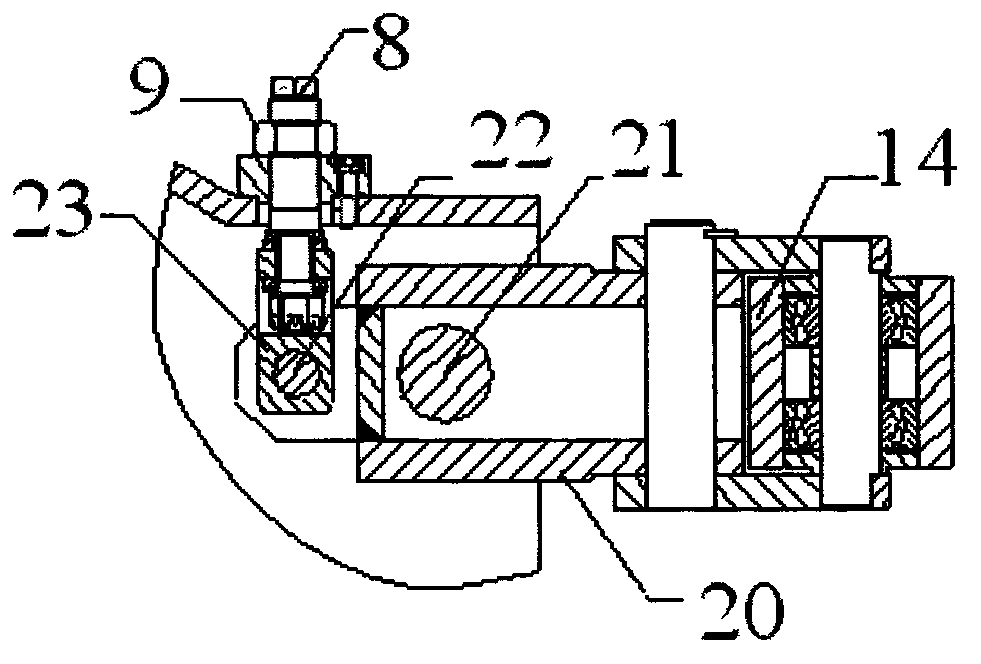

[0026] See Figure 1-6, a conical pipe seam welding pressing device (the pressure applied to the bottom of the conical pipe is completed by the conveying device trolley 7 of the conical pipe), including two side pressure mechanisms for pressing both sides of the conical pipe, a hydraulic press And hydraulic transmission mechanism, described hydraulic machine comprises base 61, upper beam 5, the column 3 that connects base 61 and upper beam 5, the upper pressure beam 6 that slides between base and upper beam 5 by column 3 and by piston Drive the upper pressure cylinder 4 of the upper pressure beam 6, the upper pressure beam 6 is provided with an upper pressure roller seat 60 for applying pressure to the top of the tapered pipe, and the upper pressure roller seat 60 is provided with a row of rollers.

[0027] The side pressure mechanism includes a side pressure end, a side pressure cylinder 2 connected to the side pressure end by a piston, and a support base 1 fixed on the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com