Extrusion device applied to fused deposition modeling high speed 3D (Three Dimensional) printer

A technology of fused deposition modeling and 3D printers, which is applied in the field of fused deposition modeling high-speed 3D printers and 3D printing, and can solve the problems of slow running of the printing travel mechanism, heavy weight of the extrusion device, and poor control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

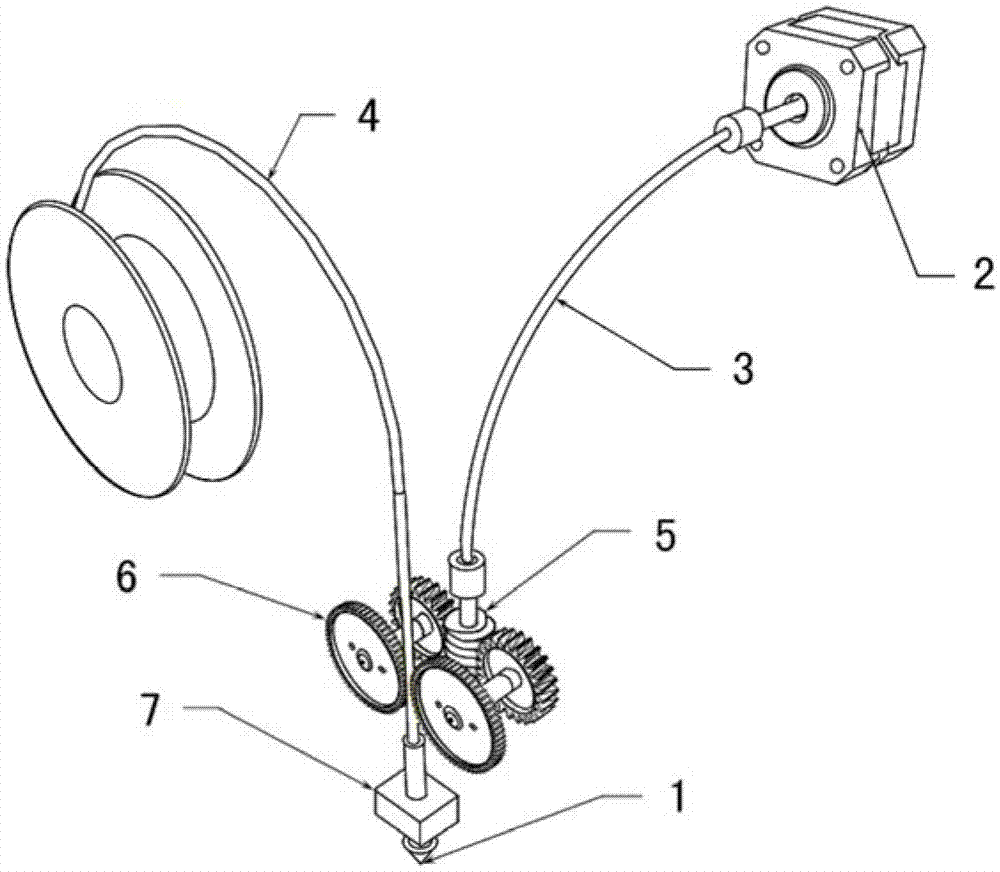

[0020] see figure 1 Shown is a schematic structural view of an extrusion device applied to a fused deposition modeling high-speed 3D printer of the present invention.

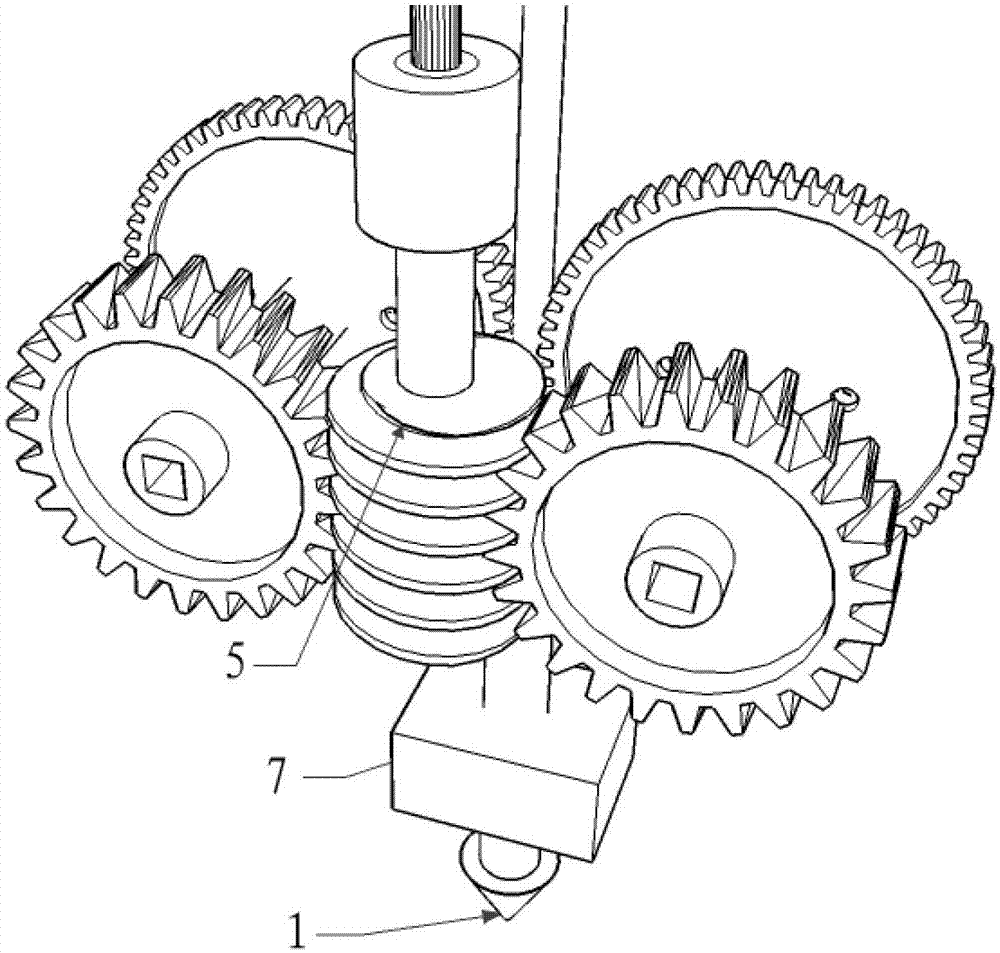

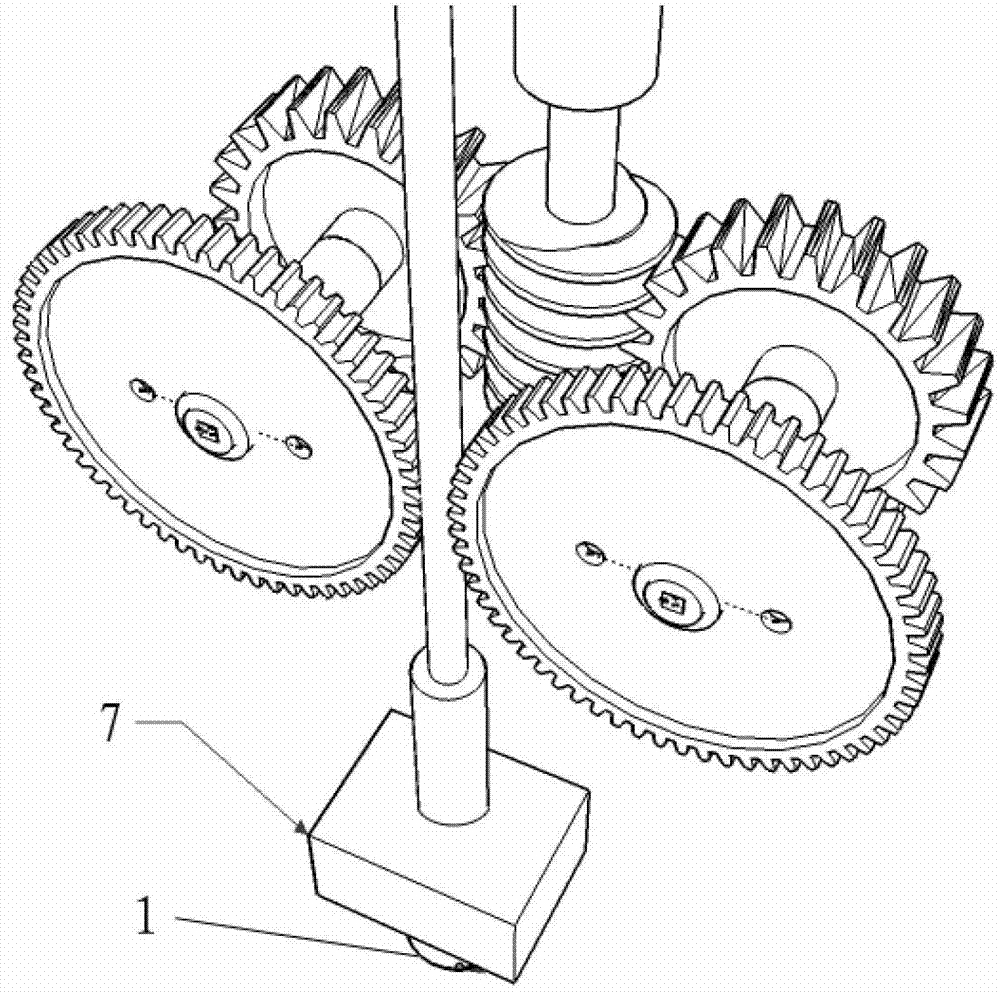

[0021] In one embodiment, an extrusion device applied to a fused deposition modeling high-speed 3D printer includes an extrusion nozzle 1, a wire feeding module and a stepping motor 2, and the wire feeding module is driven by the stepping motor 2 Next, the ABS or PLS printing wire 4 is sent to the extrusion nozzle 1 and extruded. The wire feeding module and the extrusion nozzle 1 are printing traveling mechanisms. In the case of using the flexible shaft 3 to connect the stepper motor 2 and the wire feeding module, the stepper motor 2 can be arranged on the bottom of the 3D printer, and the printing traveling mechanism can be arranged on the 3D printer the top of. The outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com