Mould for extruding and forming sintering heat preservation building block

A technology of extrusion molding and thermal insulation block, which is applied in the direction of ceramic extrusion die, etc., can solve the problems of large body, can not solve the problem of thin wall of sintered thermal insulation block, can not effectively adjust the pressure balance in the direction of extruded mud, etc. The effect of consistent wall thickness and balanced extrusion pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

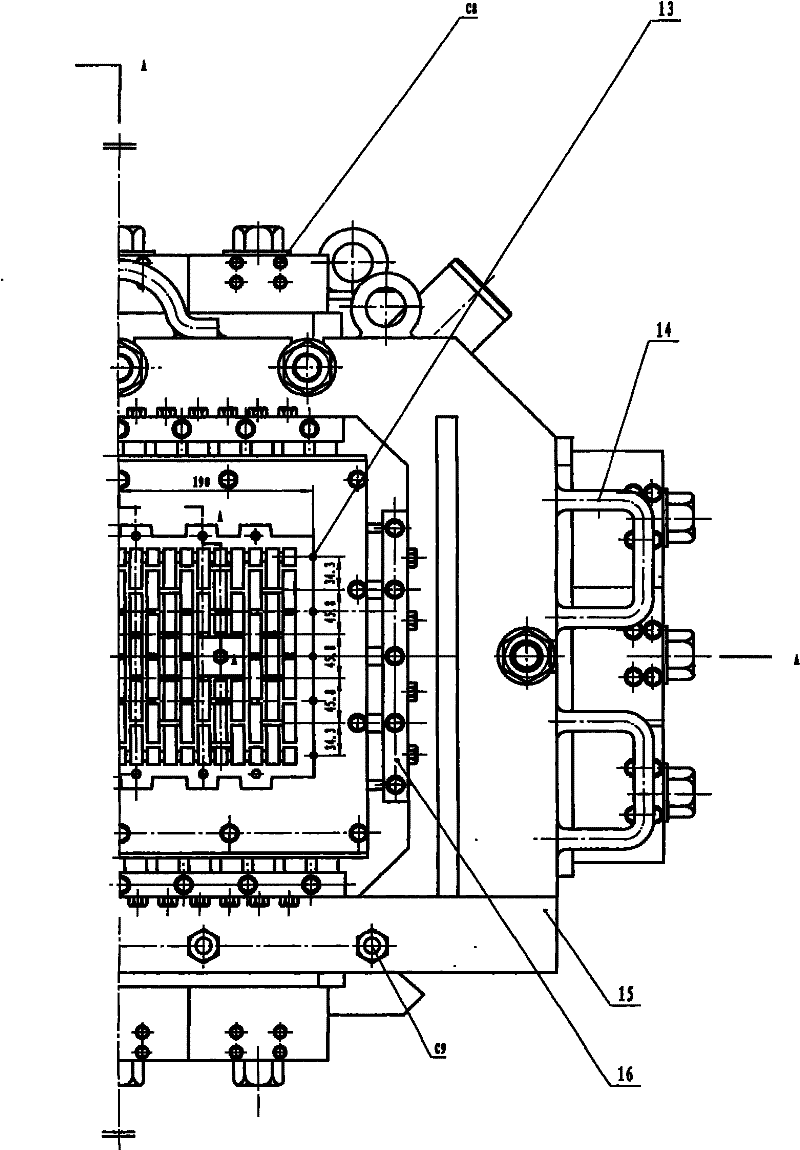

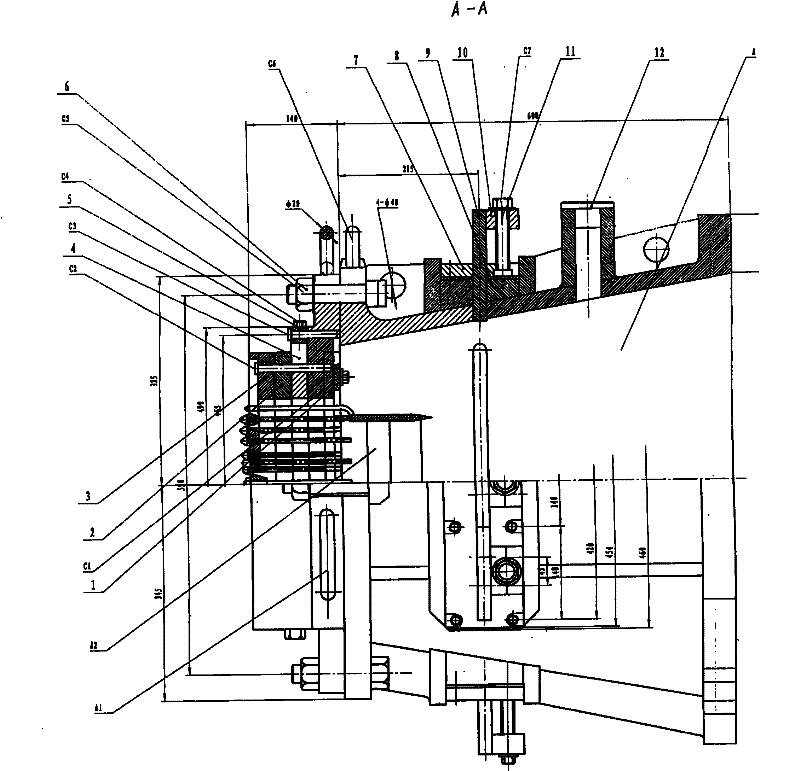

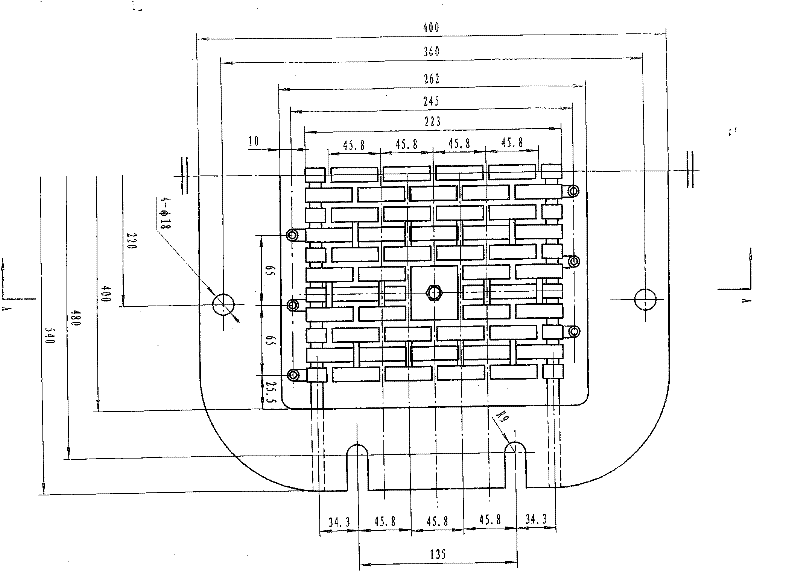

[0020] Such as Figure 1-3 As shown, the sintered heat-preserving block extrusion molding die is composed of a die A3, a die A1, and a core frame A2. The die A3 is a cone-shaped cylinder, the large end is a circular port, and the small end is a rectangular Port, the cylinder surface of the machine head A3 is equipped with 4 sets of mud adjusting inserts 9 in four directions, the small end of the machine head A3 is connected with the machine port A1, the core frame A2 is installed in the machine port A1 and the pressure plate 1 is fixed by the core frame Connect with the end face of the machine port flange; machine port A1 is composed of machine port flange, machine port partition 2, machine port panel 3, mud adjusting block 4 and layering strips (5, 16). The inner ports of each piece are kept concentric and used in sequence The bolts are fixed as a whole; there are 32 pieces of mud adjusting block 4 on the machine port A1, which are installed in four groups between the machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com