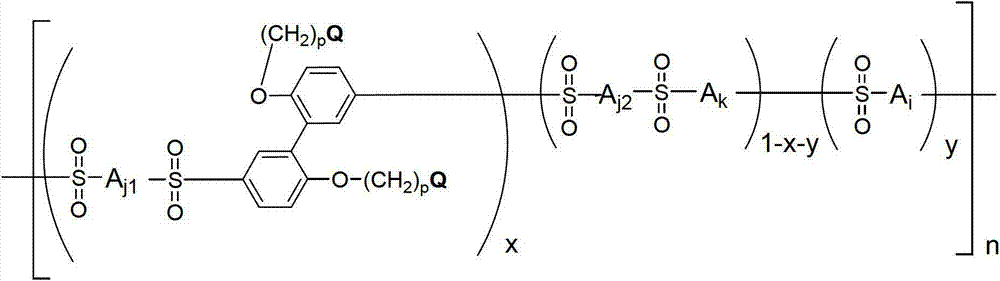

A kind of polysulfone with side chain containing quaternary ammonium group and preparation method thereof

A technology of quaternary ammonium groups and side chains, applied in the field of polymers and their preparation, can solve problems such as difficult introduction of quaternary ammonium groups, complicated steps, and inability to meet long-term use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

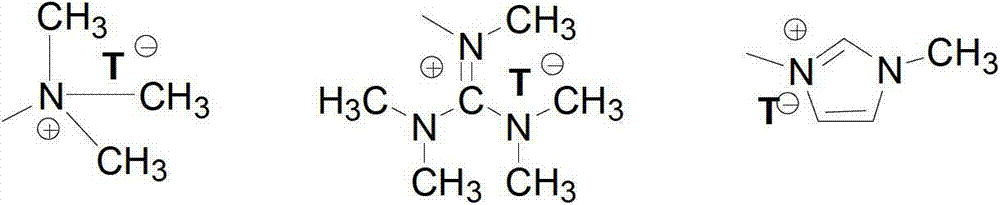

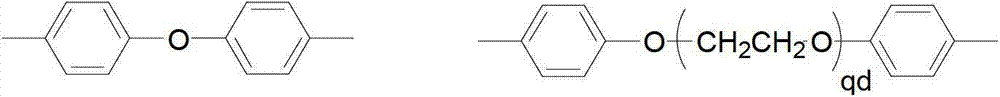

Method used

Image

Examples

Embodiment 1

[0082] 0.01 moles of 2,2, -bis(4-trimethylamino)butoxybiphenyl dibromide, 1.00 moles of 4,4, -diphenyl ether disulfonic acid, 0.99 moles of 2,2, -bis Methoxybiphenyl and 4 liters of trifluoromethanesulfonic acid were added to the reaction flask with nitrogen, and the reaction was stirred at 60 ° C for 48 hours. The reaction solution was poured into a large amount of deionized water while hot to obtain polymer precipitation. Wash repeatedly until the filtrate is neutral, soak the obtained polymer with 1 mol / L sodium hydroxide aqueous solution at room temperature for 24 hours, and vacuum dry at room temperature to obtain OH - A polymer with quaternary ammonium groups present in the side chains. In the infrared spectrum at 1310cm -1 with 1150cm -1 Strong stretching vibration peaks of sulfone groups appeared on the left and right, indicating the occurrence of sulfone-based polymerization. The structure of the obtained polymer and the proportion of each structural unit calculated...

Embodiment 2

[0087] 0.01 moles of 2,2,-bis(4-trimethylamino)butoxybiphenyl dibromide prepared according to the method of Example 1, 1.00 moles of 4,4,-diphenyl ether disulfonic acid, 0.99 Molar 2,2,-dimethoxybiphenyl and 4 liters of trifluoromethanesulfonic acid were added to the reaction flask with nitrogen, and the reaction was stirred at 80 °C for 24 hours, and the reaction solution was poured into a large amount of deionized water while hot to obtain polymerization. The polymer was precipitated, filtered and repeatedly washed with deionized water until the filtrate was neutral. The obtained polymer was soaked in a 1 mol / L sodium hydroxide aqueous solution at room temperature for 24 hours, and then vacuum-dried at room temperature to obtain OH - A polymer with quaternary ammonium groups present in the side chains. In the infrared spectrum at 1310cm -1 with 1150cm -1 Strong stretching vibration peaks of sulfone groups appeared on the left and right, indicating the occurrence of sulfone...

Embodiment 3

[0089] 0.01 moles of 2,2,-bis(4-trimethylamino)butoxybiphenyl dibromide prepared according to the method of Example 1, 1.00 moles of 4,4,-diphenyl ether disulfonic acid, 0.99 Molar 2,2,-dimethoxybiphenyl and 4 liters of trifluoromethanesulfonic acid were added to the reaction flask with nitrogen, and the reaction was stirred at 100 ° C for 10 hours, and the reaction solution was poured into a large amount of deionized water while hot to obtain polymerization. The polymer was precipitated, filtered and repeatedly washed with deionized water until the filtrate was neutral. The obtained polymer was soaked in a 1 mol / L sodium hydroxide aqueous solution at room temperature for 24 hours, and then vacuum-dried at room temperature to obtain OH - A polymer with quaternary ammonium groups present in the side chains. In the infrared spectrum at 1310cm -1 with 1150cm -1 Strong stretching vibration peaks of sulfone groups appeared on the left and right, indicating the occurrence of sulfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com