Sliding-compact-type pipe fitting for aluminum-plastic pipe

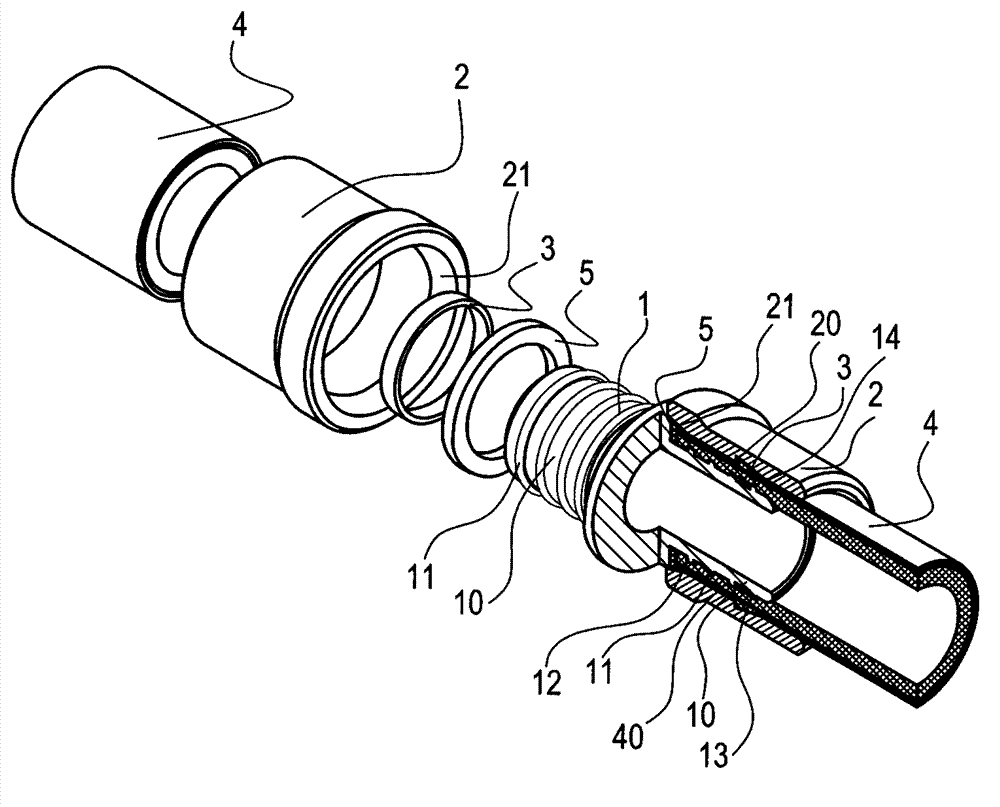

A sliding-tight, aluminum-plastic pipe technology, applied in the direction of pipes/pipe joints/fittings, through components, sleeves/sockets, etc., can solve the problems of high cost, impossibility of universal use, poor memory of pipes, etc., and achieve reliable sealing The effect of improving sexuality, making up for the lack of memory, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

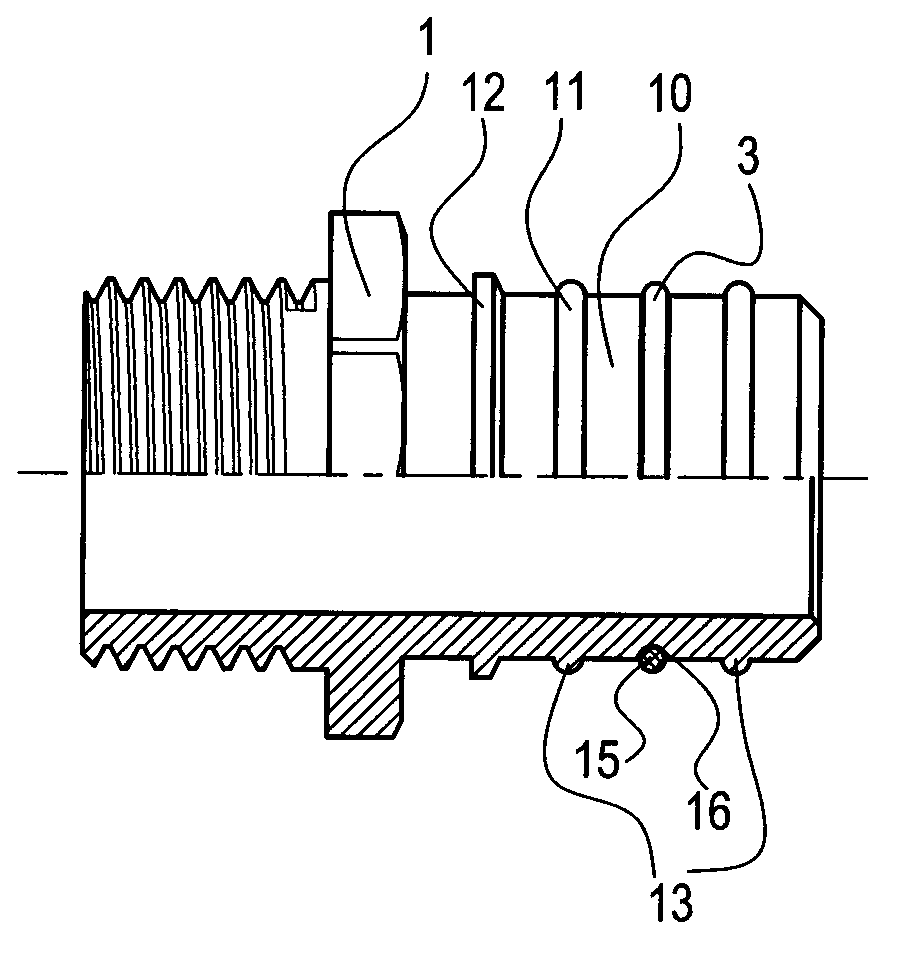

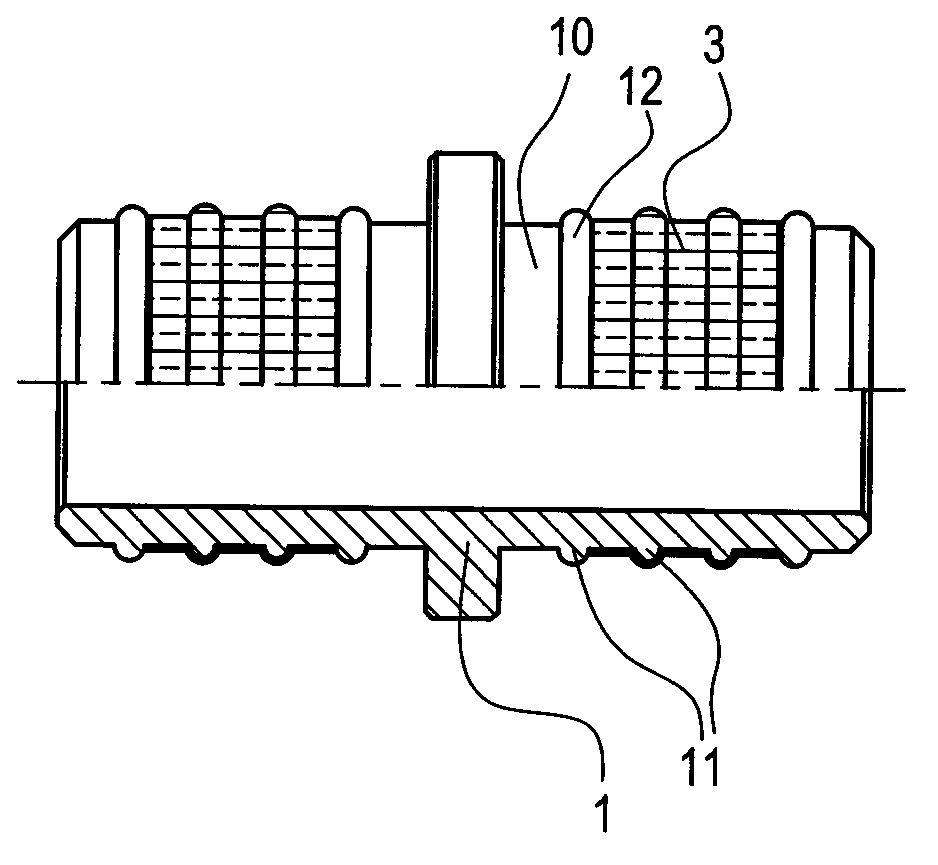

[0026] Embodiment four is similar to the above-mentioned several embodiments, as Figure 4 As shown, there are three ribs 11 on the inner tube support 10, the ribs 11 are not semicircular, but a rib with a taper is used, and the other two are ring-shaped sealing rings 3, the cross-section of the sealing ring 3 is generally triangular in shape, set In the groove 16 of the outer diameter of the inner tube support 10, both are located between the two convex ribs 11. The sealing ring 3 can be made of sealing materials such as EPDM, NBR, silicone rubber, etc., or can be made of composite compressed fiber material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com