Handheld universal measuring instrument for M values of internal splines

An internal spline, hand-held technology, applied in the field of hand-held general-purpose measuring instruments, can solve the problems such as the inability to measure the actual value of the spline M value, the large influence of human factors, and the infeasibility of mass production. Not easy to wear and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

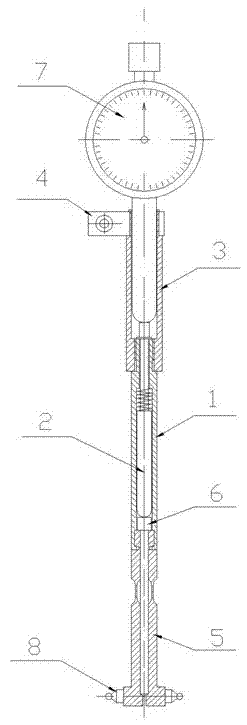

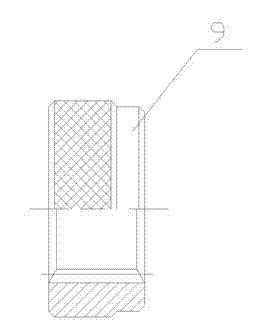

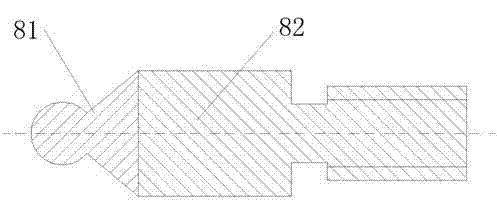

[0014] Such as figure 1 As shown, the hand-held internal spline M value universal measuring instrument of the present invention includes a body 1, an elastic body 5, a chuck 4, a chuck expansion sleeve 3, a transmission rod 2, a dial gauge 7, a thimble 6, and a measuring head 8 and Calibration Kit 9 (see also figure 2 ), the calibration piece 9 is used for the calibration of the zero reference. The middle of the body 1 is provided with an inner cavity opened up and down. The upper end of the elastic body 5 is engaged and fixed on the lower end of the body 1 , and its upper end extends into the inner cavity of the body 1 . The measuring head 8 is placed at the lower end of the elastic body 5 . The transmission rod 2 is placed in the inner cavity of the body 1, and the thimble 6 is arranged in the inner cavity of the main body 1, above the elastic body 5, and the lower end of the transmission rod 2 is connected to the upper end of the thimble 6. The table chuck 4 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com