Round spring test device

A testing device and circular spring technology, used in measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as accurate detection of the performance of axleless boxes and bolster springs, and improve testing efficiency and accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

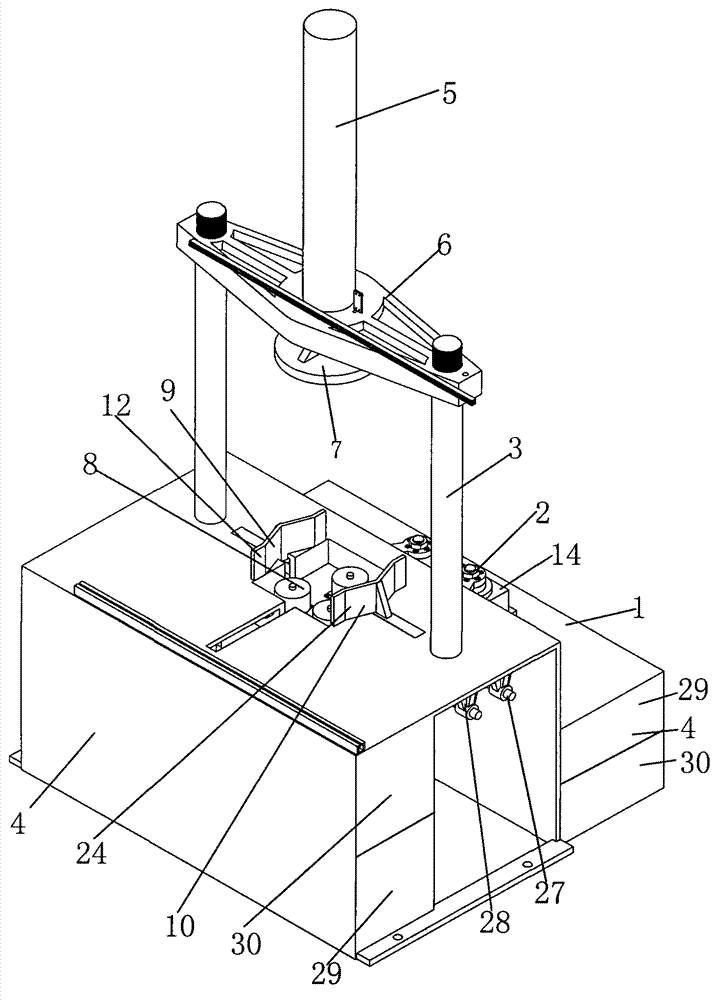

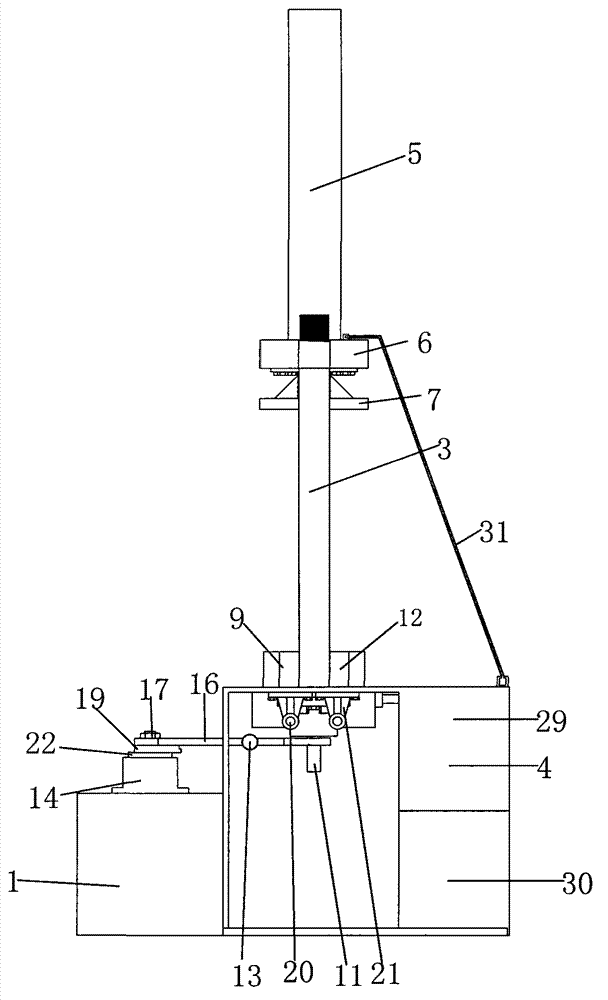

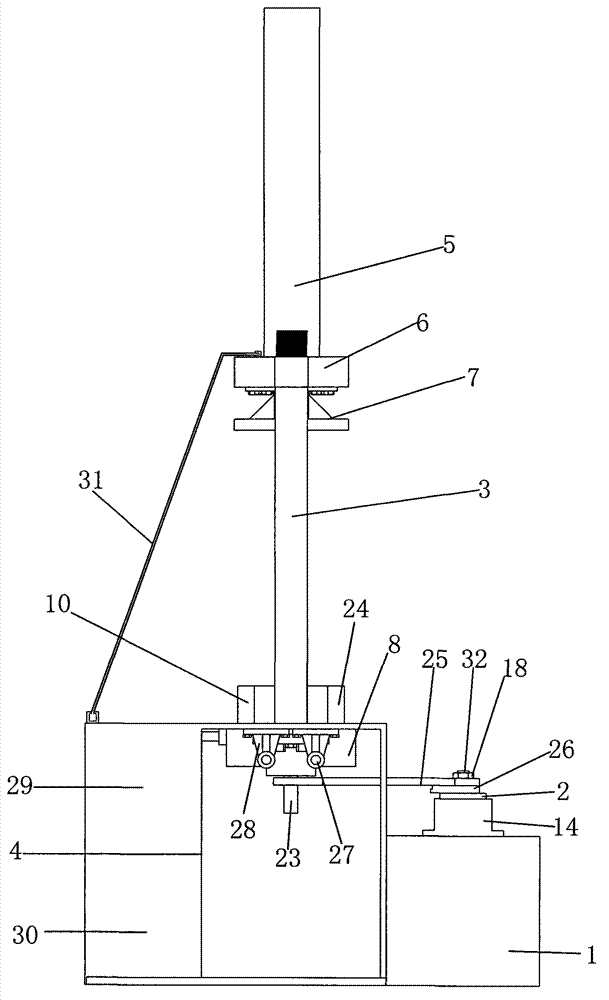

[0020] Such as Figure 1-4 As shown, the round spring test device, base 1, centering assembly 2, bracket 3, hydraulic system assembly 4, main hydraulic cylinder 5, upper beam 6, and centering assembly 2, bracket 3 are fixedly installed on the base 1. The hydraulic system assembly 4 is fixedly installed on one side of the base 1, the upper beam 6 is fixed on the bracket 3, the main hydraulic cylinder 5 is fixed on the upper beam 6, and the main hydraulic cylinder 5 is provided with a displacement sensor 7. A force sensor 8 is provided between the base 1 and the centering assembly 2 of

[0021] Such as Figure 5-7 As shown, the centering assembly 2 includes an active centering part 9 and a following centering part 10. The active centering part 9 and the following centering part 10 are symmetrically installed and connected, and the active centering part 9 includes a first sliding part. Seat 11, first scraper 12, positioning cylinder 13, shift fork fixing base 14, positioning cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com