Automatic assembling machine of photovoltaic junction box wire bracket

A wire support and junction box technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of poor product installation consistency, low one-time pass rate, low efficiency, etc., and improve production efficiency and product pass rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

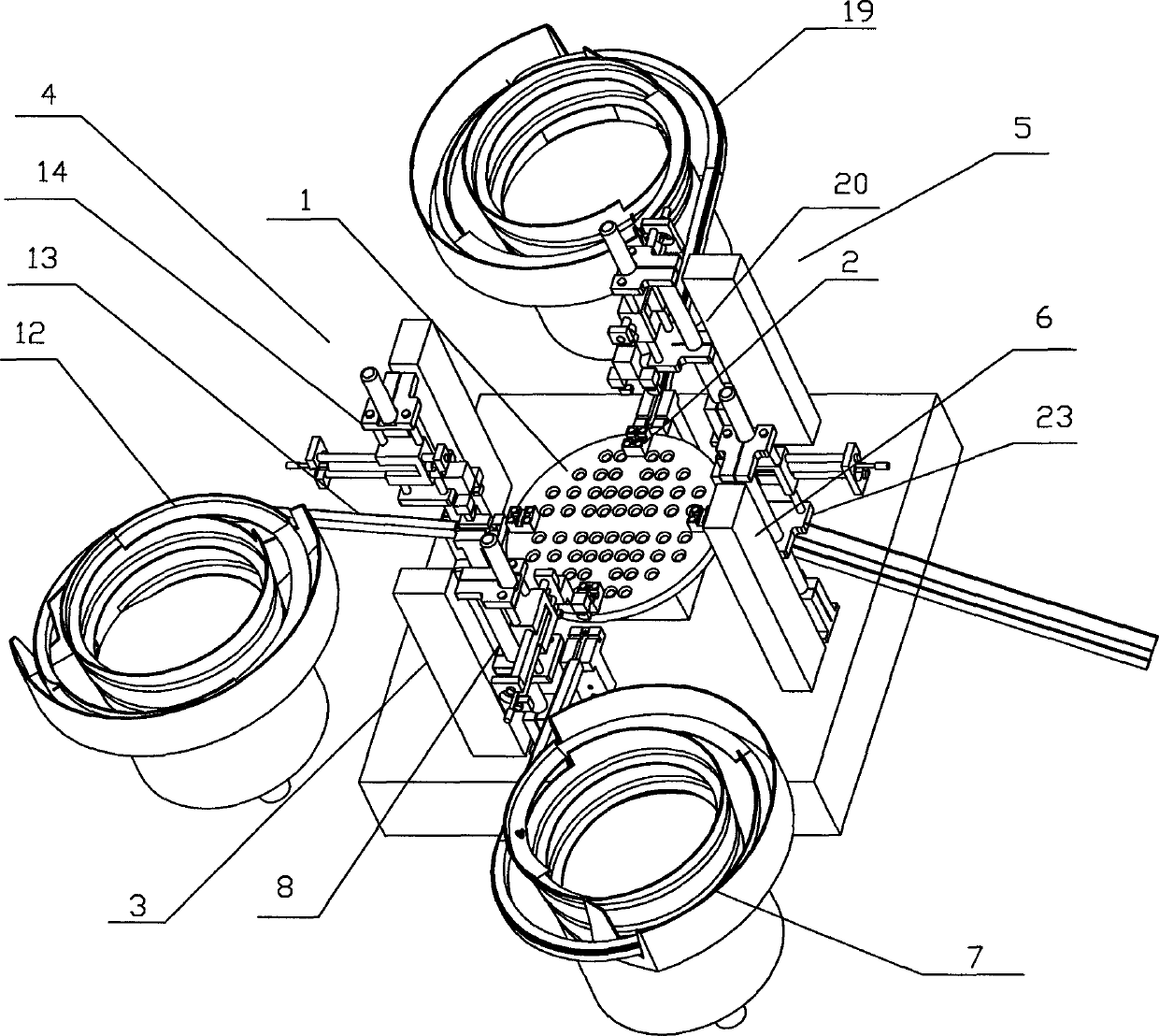

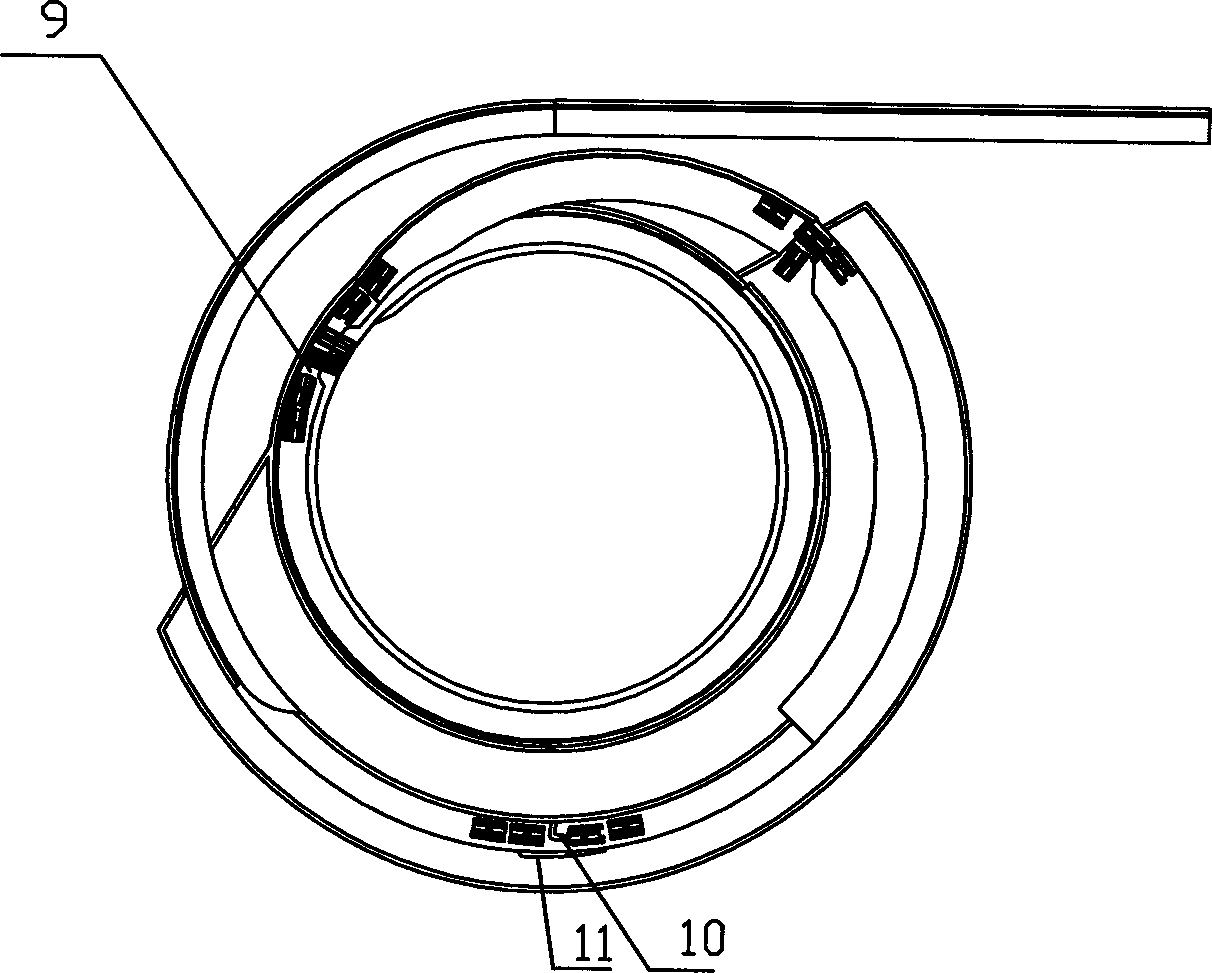

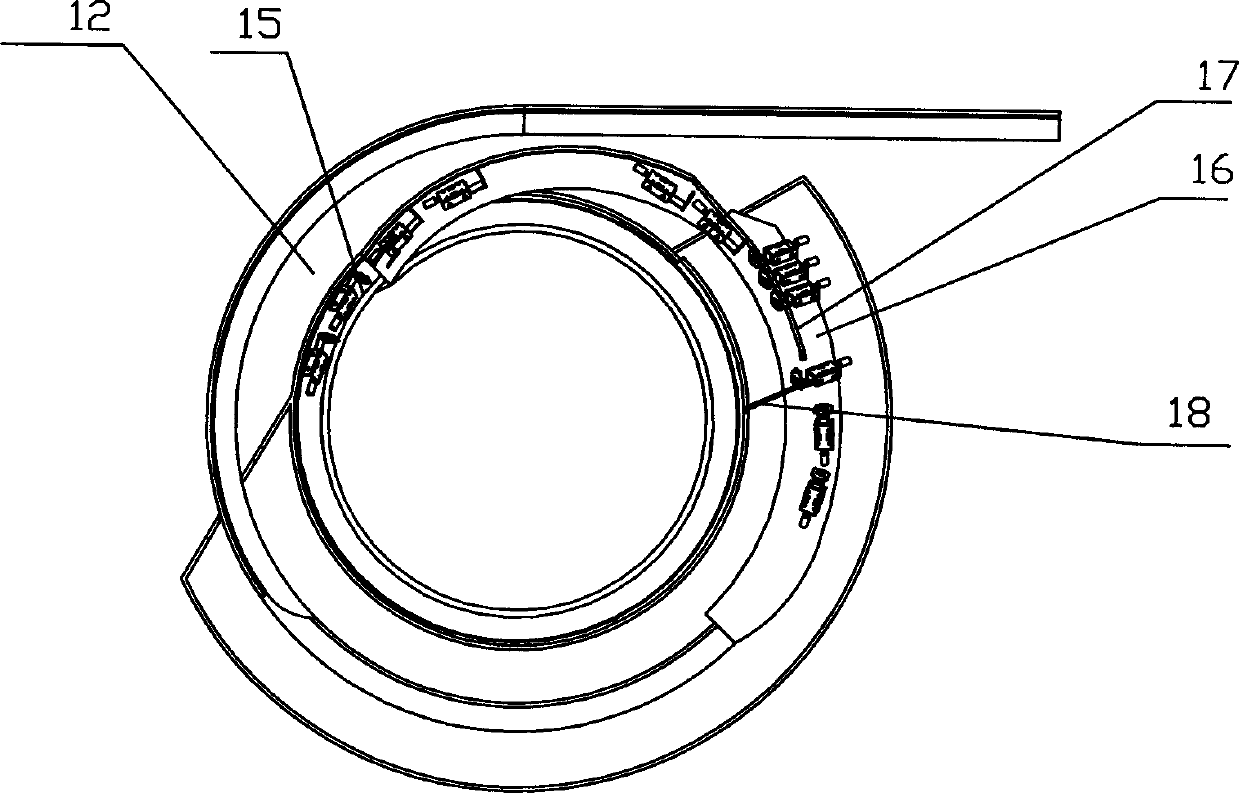

[0026] Such as Figure 1-7 As shown, an automatic assembly machine for a photovoltaic junction box wire support includes an assembly table 1, which is rotatably mounted on a base, and four workpiece positioning mechanisms 2 are respectively arranged on the periphery of the assembly table in the circumferential direction. The included angle adjacent to the workpiece positioning mechanism 2 is 90 degrees. Around the assembly table and corresponding to the position of the workpiece positioning mechanism 2, there are successively provided a tube support spring assembly mechanism 3, a metal wire bracket assembly mechanism 4, a triangular circlip assembly mechanism 5 and a drop spring assembly mechanism. The material mechanism 6; the pipe support spring assembly structure 3 includes a first vibrating plate 7, a first conveying mechanism con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com