Porous silicon nitride ceramic and production method thereof

A technology of silicon nitride ceramics and silicon nitride powder, which is applied in the preparation of porous silicon nitride ceramics by self-propagating method, porous silicon nitride ceramics and the preparation of porous silicon nitride ceramics by self-propagating method, to achieve industrial scale Production, high intensity, short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] In the preparation method of the porous silicon nitride ceramics provided by the present invention, by ball milling silicon powder, silicon nitride powder and sintering aid in a ball mill jar to make it evenly mixed, and drying and passing through a 80-200 mesh sieve to obtain A mixture of certain fineness silicon powder, silicon nitride powder, and sintering aids. Wherein, the ball milling time may be 1 to 24 hours. In addition, the ratio of silicon powder to silicon nitride powder in the mixture of silicon powder, silicon nitride powder and sintering aid can be 9-5:1-5; the ratio is preferably 7-5:3-5. Also, the sintering aid can be Y 2 o 3 , Yb 2 o 3 、Lu 2 o 3 、Nd 2 o 3 、Er 2 o 3 one or more of them.

[0029] In the preparation method of the porous silicon nitride ceramic provided by the present invention, when the molded body having a certain shape after molding is subjected to nitriding treatment, in order to promote the formation of the molded body obta...

Embodiment 1

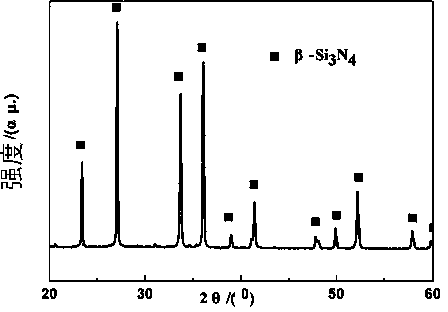

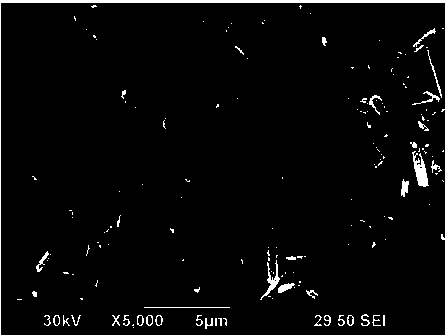

[0035] Using ethanol as a solvent and silicon nitride balls as a ball milling medium, silicon powder, silicon nitride powder and yttrium oxide were ball milled in a ball mill jar for 24 hours at a mass ratio of 70:30:6. The uniformly mixed slurry was dried in an oven at 60°C, and then passed through a 100-mesh sieve. The sieved powder was pressed into a porous green body with a stainless steel mold of 10 MPa. The green body is buried in the silicon / silicon nitride buried powder with the same ratio, put into the self-propagating reaction chamber, nitrogen gas is introduced, and it is synthesized by ignition and combustion. The reaction time is 4 minutes. After the synthesis, it is naturally cooled in the furnace; Know: the porosity of the porous silicon nitride ceramic material that the present embodiment makes is 54%, and flexural strength is 120MPa; figure 1 It is the XRD figure of the porous silicon nitride ceramic material after the self-propagating reaction in embodiment ...

Embodiment 2

[0037] Using ethanol as a solvent and silicon nitride balls as a ball milling medium, silicon powder, silicon nitride powder and ytterbium oxide were ball milled in a ball mill jar for 24 hours at a mass ratio of 50:50:6. The uniformly mixed slurry was dried in an oven at 60°C, and then passed through a 100-mesh sieve. The sieved powder is pressed into a porous green body with a stainless steel mold of 5 MPa. The porous green body is buried in the silicon / silicon nitride buried powder with the same ratio, put into the self-propagating reaction chamber, and nitrogen gas is introduced, and it is synthesized by ignition and combustion. The reaction time is 3 minutes, and it is naturally cooled in the furnace after synthesis;

[0038] After testing, it is known that the porosity of the porous silicon nitride ceramic material prepared in this embodiment is 59%, and the flexural strength is 110MPa;

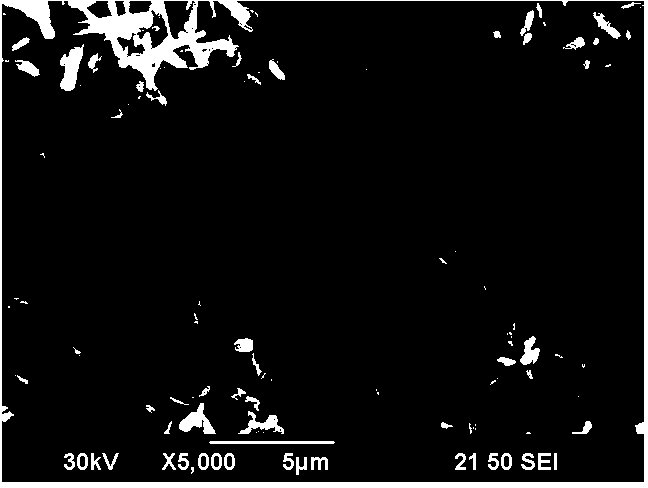

[0039] see image 3 , which shows the scanning electron micrograph of the porous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com