Patents

Literature

32results about How to "Facilitate the realization of industrial scale production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

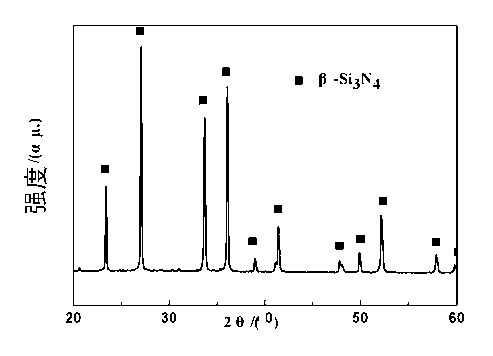

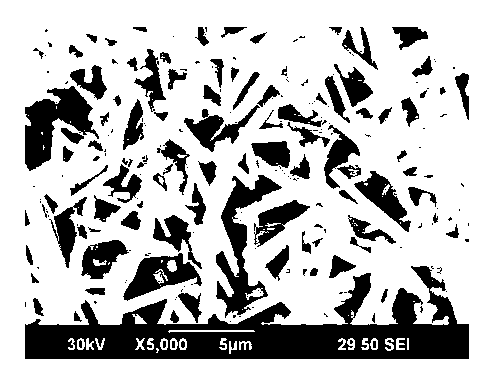

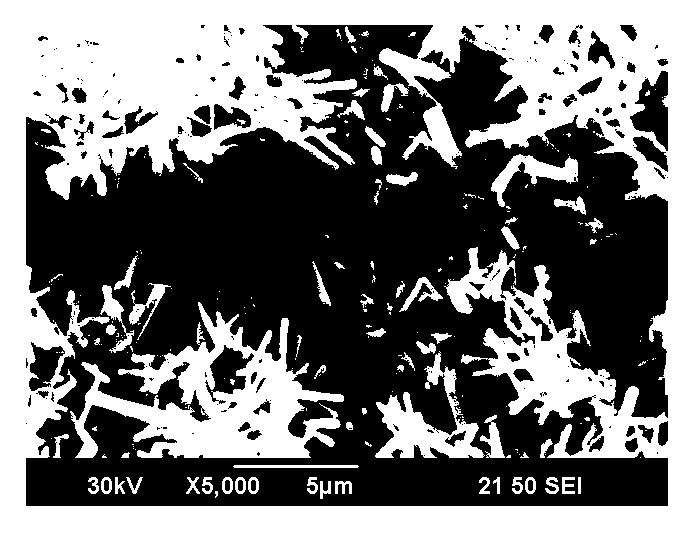

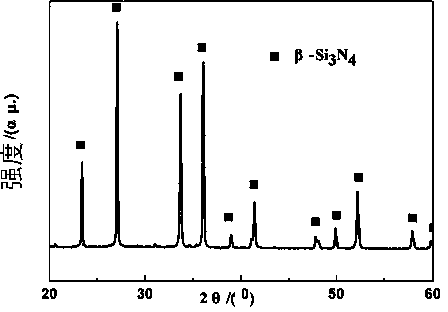

Porous silicon nitride ceramic and production method thereof

ActiveCN103121854AFacilitate the realization of industrial scale productionHigh strengthCeramicwareNitrideCeramic

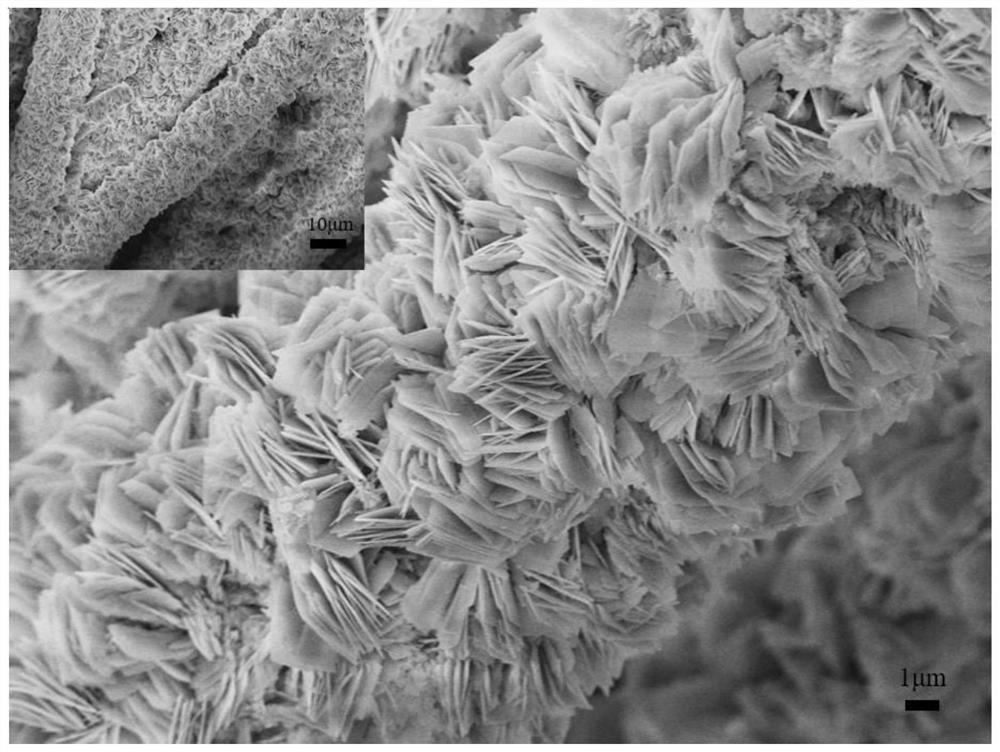

The invention relates to porous silicon nitride ceramic and a production method thereof. A product of the porous silicon nitride ceramic has silicon nitride in beta-phase silicon nitride crystal form in cylinder or rod shape. The product is 20-65% in total porosity and 450-50MPa in bending strength. The silicon nitride in the product of porous silicon nitride ceramic is in the beta-phase crystal form in the cylinder or rod shape, and strength and toughness of the product can be improved further.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

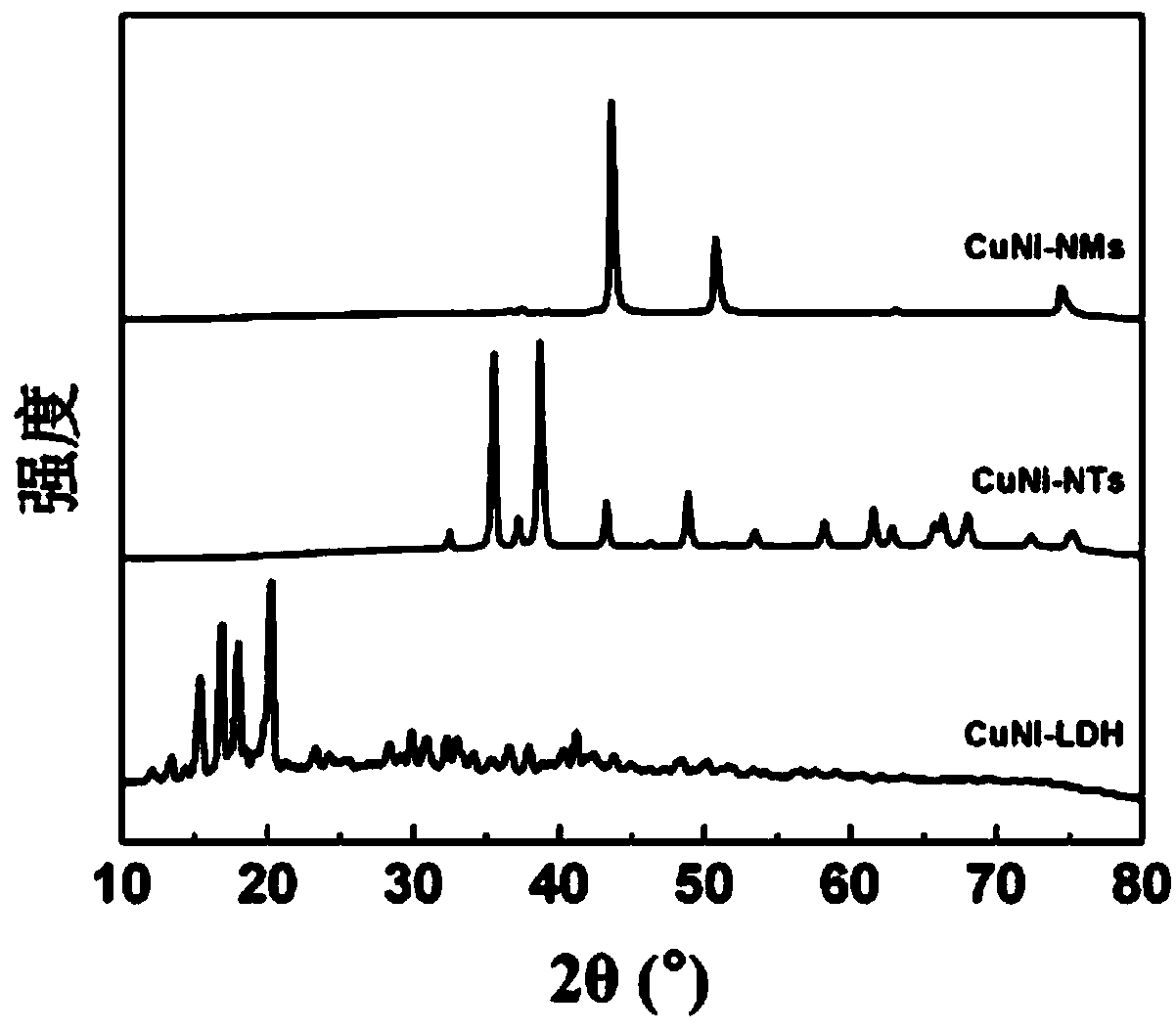

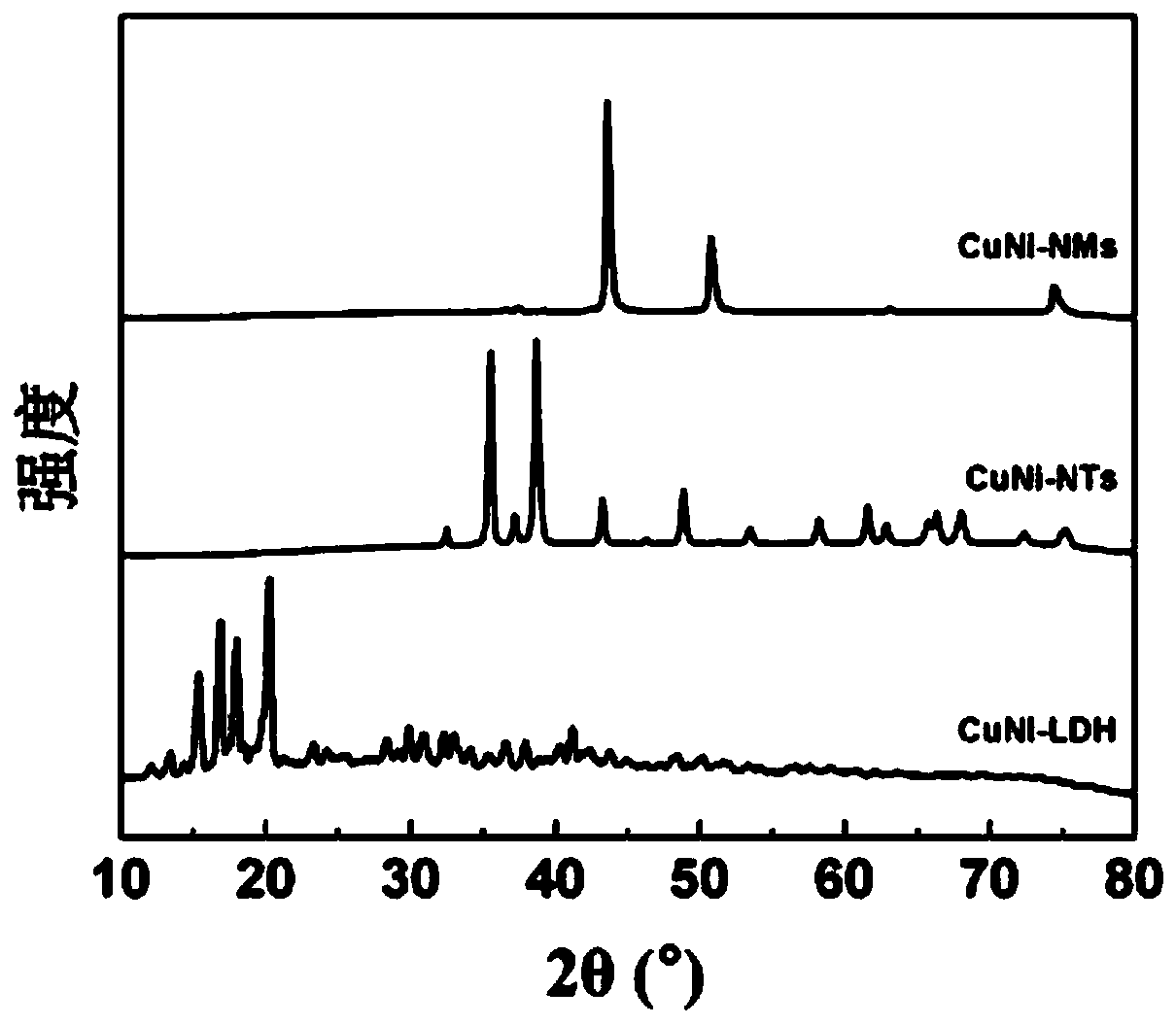

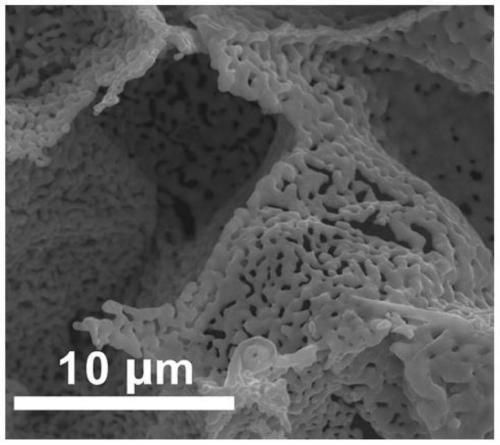

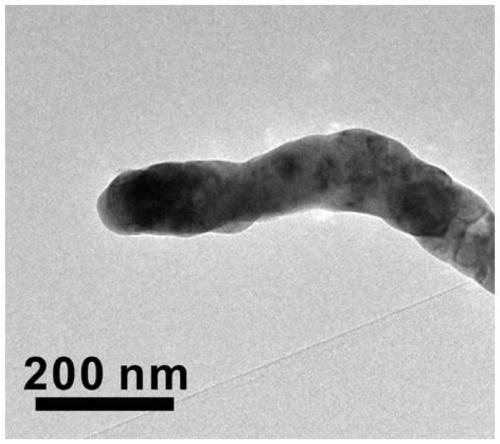

Preparation and application methods of Cu-Ni-based catalyst for reversed water gas reaction

ActiveCN109499577AAvoid structureReduce manufacturing costCarbon monoxideMetal/metal-oxides/metal-hydroxide catalystsNickel saltMixed gas

The invention relates to preparation and application of catalysts and aims at providing preparation and application methods of a Cu-Ni-based catalyst for reversed water gas reaction. The preparation method comprises the following steps: dissolving soluble copper salt and soluble nickel salt into a mixed solution of water and ethanol; adding a complexing agent and reacting under heating and stirring conditions to obtain CuNi hydrotalcite; drying and roasting to prepare CuNi mixed oxide with a nanotube structure; after carrying out reduction reaction in a mixed gas atmosphere of flowing H2 and Ar, naturally cooling to room temperature, so as to obtain the Cu-Ni-based catalyst. The complexing preparation method provided by the invention is simple and feasible; influences, caused by uncertainfactors in a preparation process, on the structure and performance of the catalyst are avoided. Active components of the catalyst comprise copper and nickel and any noble metal is not used so that thepreparation cost of the catalyst is relatively low, and industrial large-scale production of the catalyst is easy to realize. The catalyst can be used for a CO synthesis technology and is further connected with a CO hydrogenation catalyst in series to produce alcohols and hydrocarbons with high additional value, so that the catalyst has an application prospect.

Owner:ZHEJIANG UNIV

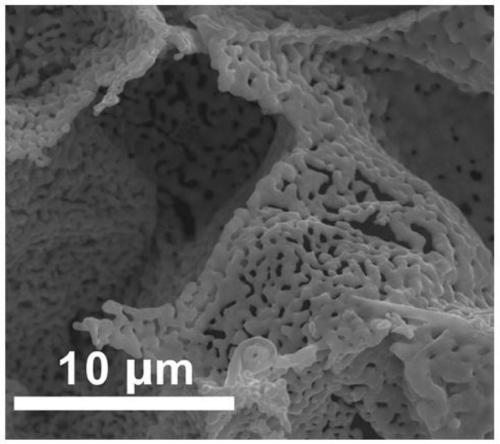

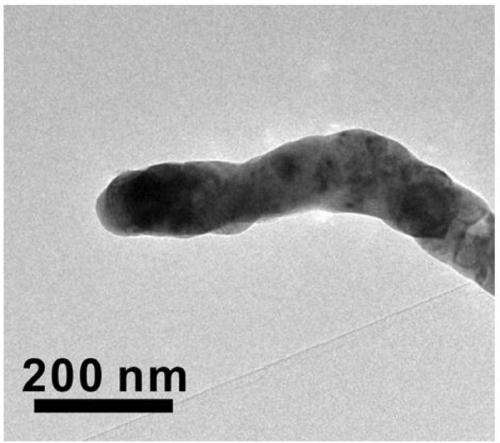

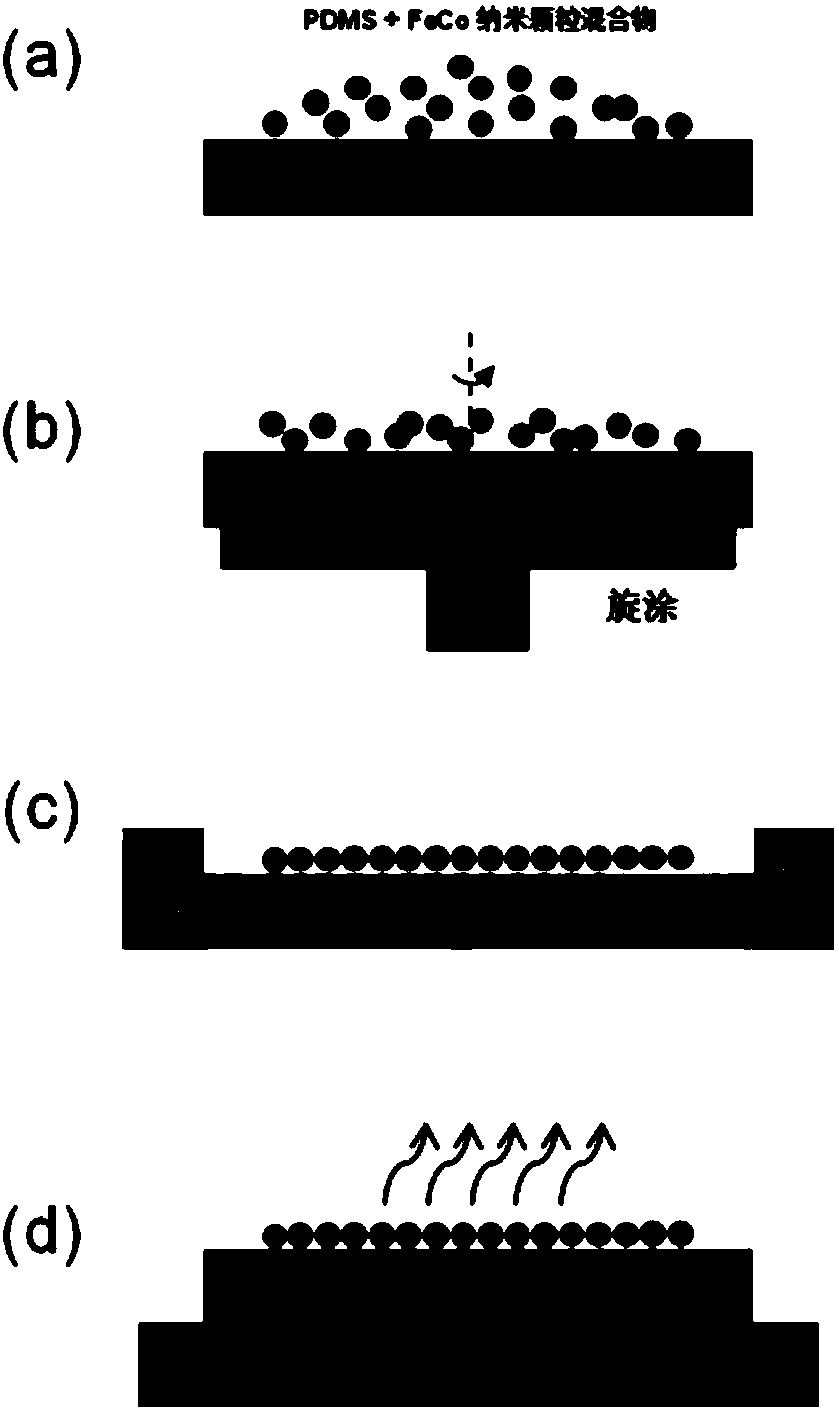

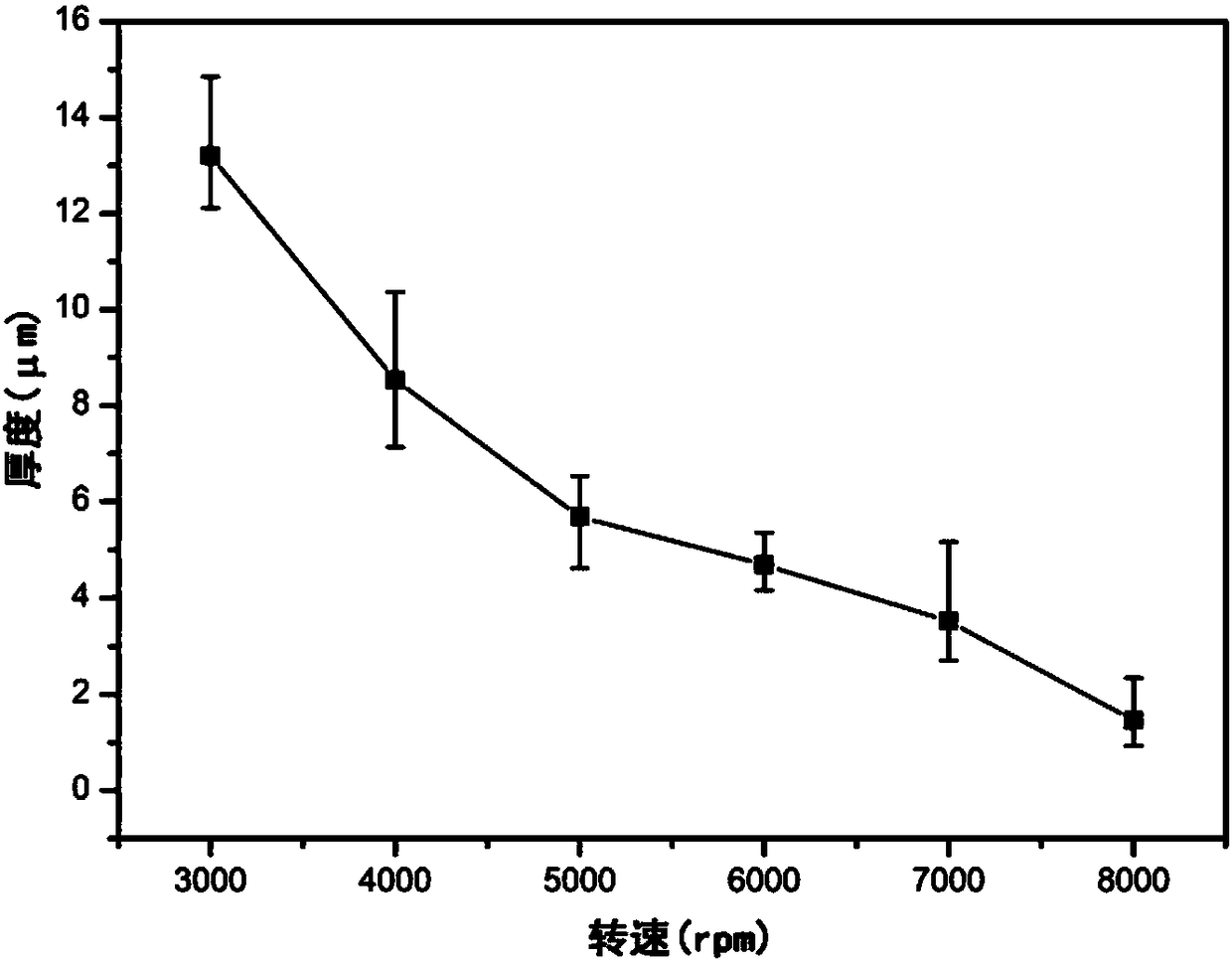

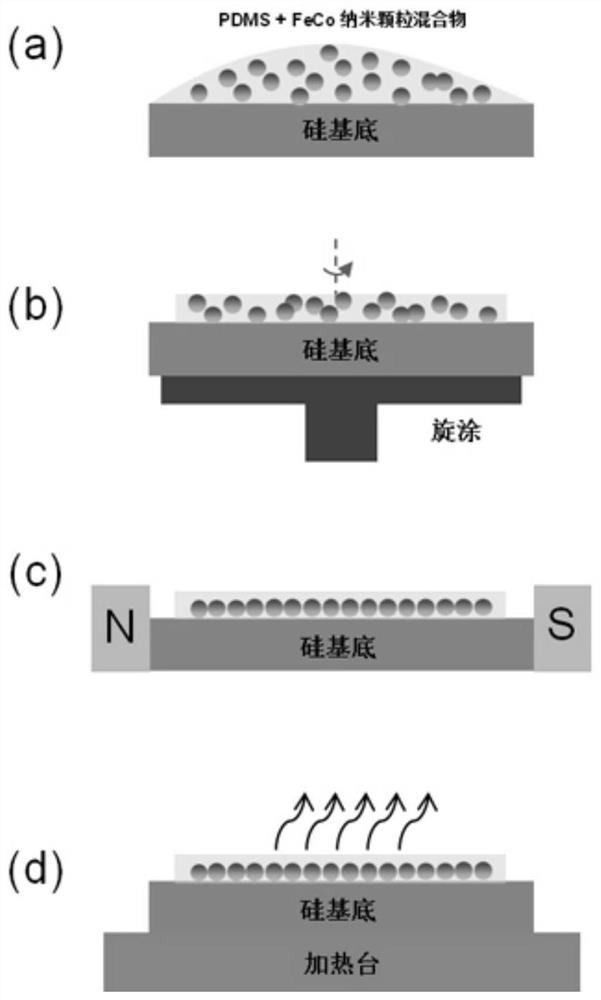

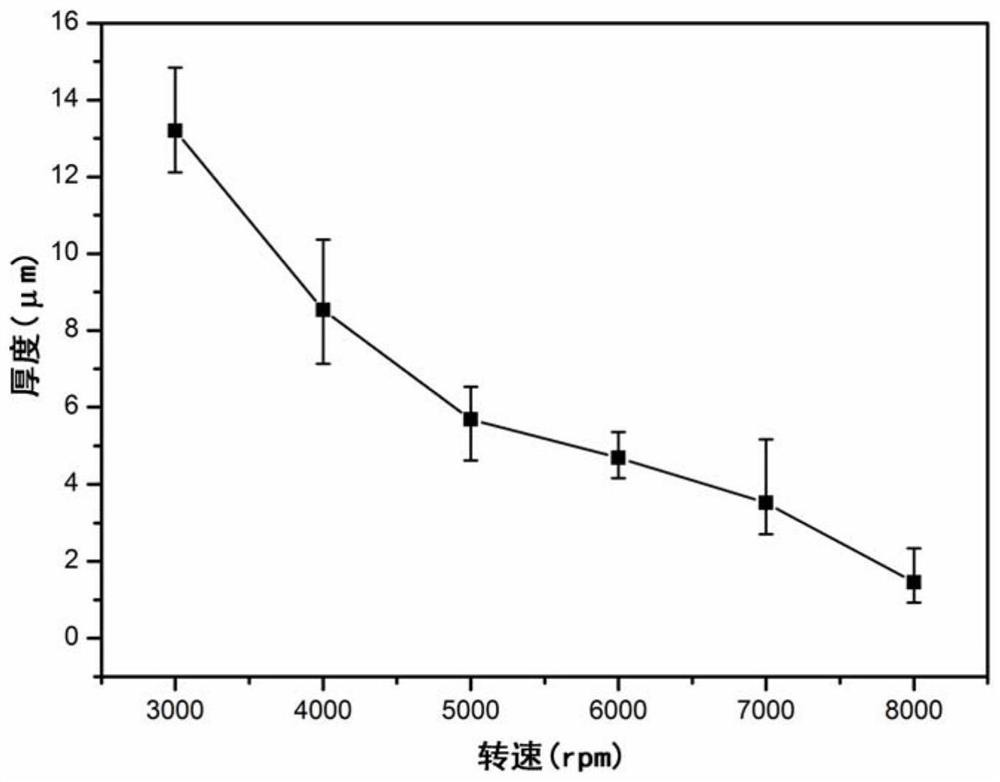

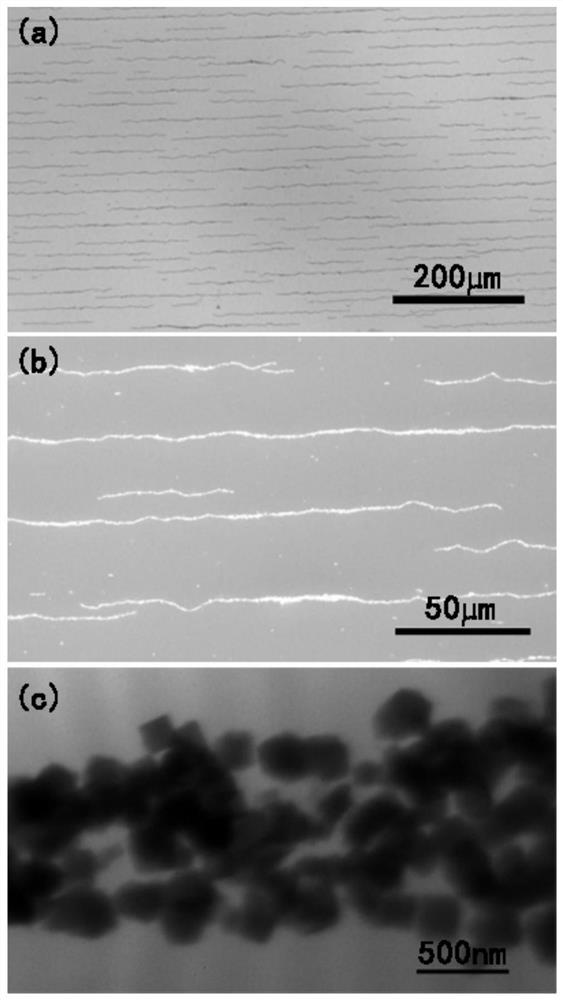

Aeolotropic magnetic high polymer composite film material and preparation method thereof

The invention discloses an aeolotropic magnetic high polymer composite film material and a preparation method of the material and belongs to the technical field of magnetic high polymer composites. The composite film material comprises an FeCo magnetic nano particle and a polymer matrix. The method comprises the steps of: 1) adding the FeCo cubic magnetic nanoparticle into a high molecular polymerfor uniform stirring to form a mixture, and 2) spin-coating a glass sheet or a silicon sheet with the obtained mixture to form a film, putting the prepared film in a magnetic field for magnetic particle self-assembly, and performing curing at a certain temperature to form the aeolotropic magnetic high polymer composite film. A technology is simple; film thickness is easy to control; and the material contains an aeolotropic self-assembly nano rope, is good in directionality, high in production efficiency, good in mechanical property and has a potential application in the high and new technicalfield of flexible magnetic devices and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

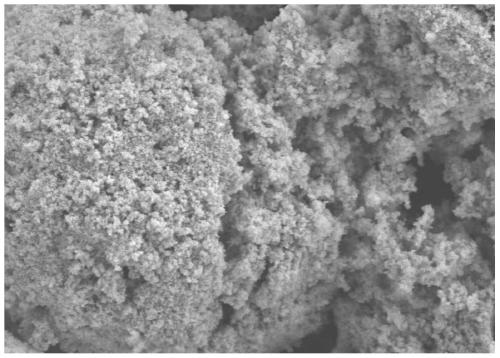

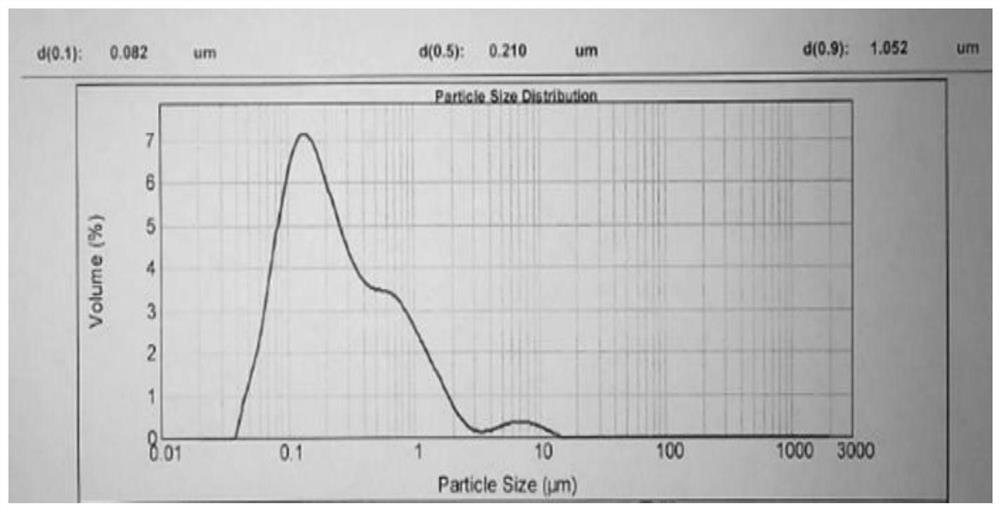

Preparation method of nanometer indium hydroxide

The invention provides a preparation method of nanometer indium hydroxide. The preparation method comprises the following steps: a) introducing ammonia gas into an aqueous indium nitrate solution to obtain a precursor slurry; and b) washing the precursor slurry, and performing spray drying to obtain an indium hydroxide powder. The preparation method provided by the invention can reduce the production of an ammonia nitrate mother liquor, reduce the washing difficulty and the consumption of washing water, reduce the generation of nitrogen-containing wastewater and reduce the wastewater treatmentdifficulty; the preparation method allows the nano-level product to be obtained without a dispersant, so the preparation cost is reduced, the operation steps are simplified, and impurities in the slurry are reduced, thereby the washing difficulty and the consumption of washing water are reduced; and the obtained product has small particle size and a good uniformity, and does not need to be sieved, so the preparation process is simplified.

Owner:先导薄膜材料(安徽)有限公司

Preparation and application method of Cu-Ni based catalyst for reverse water gas reaction

ActiveCN109499577BAvoid structureReduce manufacturing costCarbon monoxideMetal/metal-oxides/metal-hydroxide catalystsNickel saltPtru catalyst

The invention relates to preparation and application of catalysts and aims at providing preparation and application methods of a Cu-Ni-based catalyst for reversed water gas reaction. The preparation method comprises the following steps: dissolving soluble copper salt and soluble nickel salt into a mixed solution of water and ethanol; adding a complexing agent and reacting under heating and stirring conditions to obtain CuNi hydrotalcite; drying and roasting to prepare CuNi mixed oxide with a nanotube structure; after carrying out reduction reaction in a mixed gas atmosphere of flowing H2 and Ar, naturally cooling to room temperature, so as to obtain the Cu-Ni-based catalyst. The complexing preparation method provided by the invention is simple and feasible; influences, caused by uncertainfactors in a preparation process, on the structure and performance of the catalyst are avoided. Active components of the catalyst comprise copper and nickel and any noble metal is not used so that thepreparation cost of the catalyst is relatively low, and industrial large-scale production of the catalyst is easy to realize. The catalyst can be used for a CO synthesis technology and is further connected with a CO hydrogenation catalyst in series to produce alcohols and hydrocarbons with high additional value, so that the catalyst has an application prospect.

Owner:ZHEJIANG UNIV

Porous silicon nitride ceramic and production method thereof

ActiveCN103121854BFacilitate the realization of industrial scale productionHigh strengthCeramicwareBeta phaseUltimate tensile strength

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

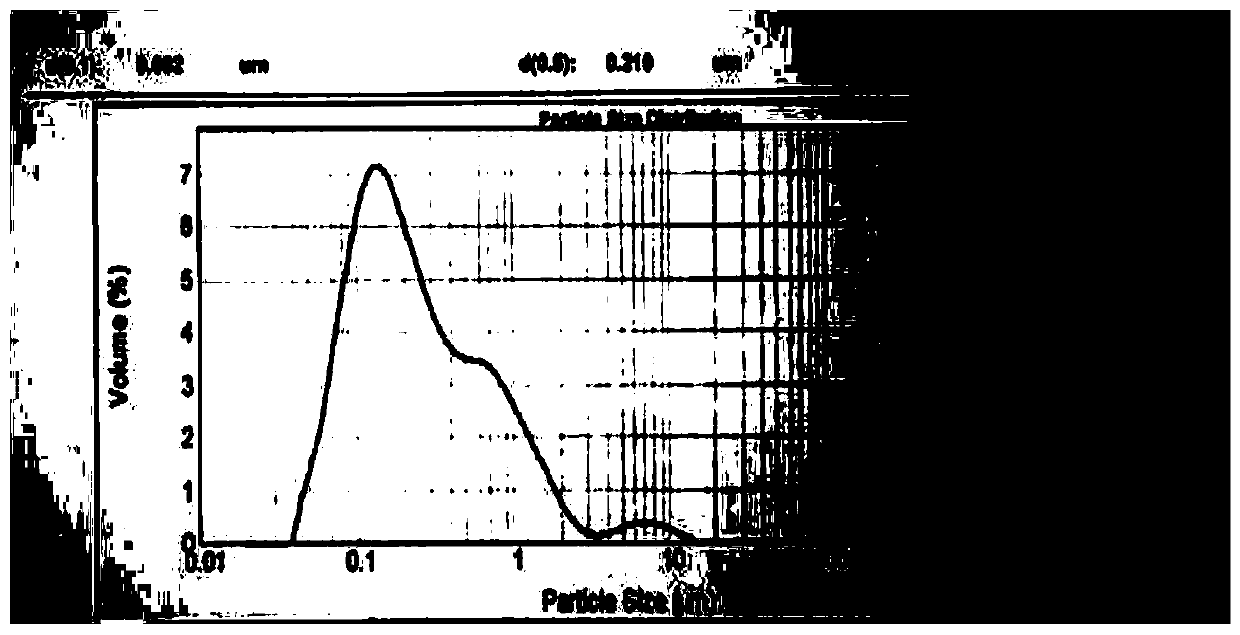

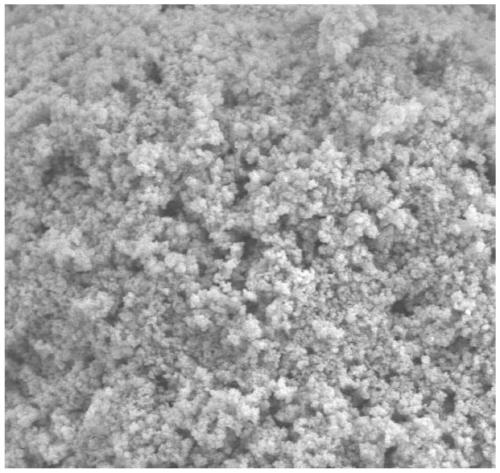

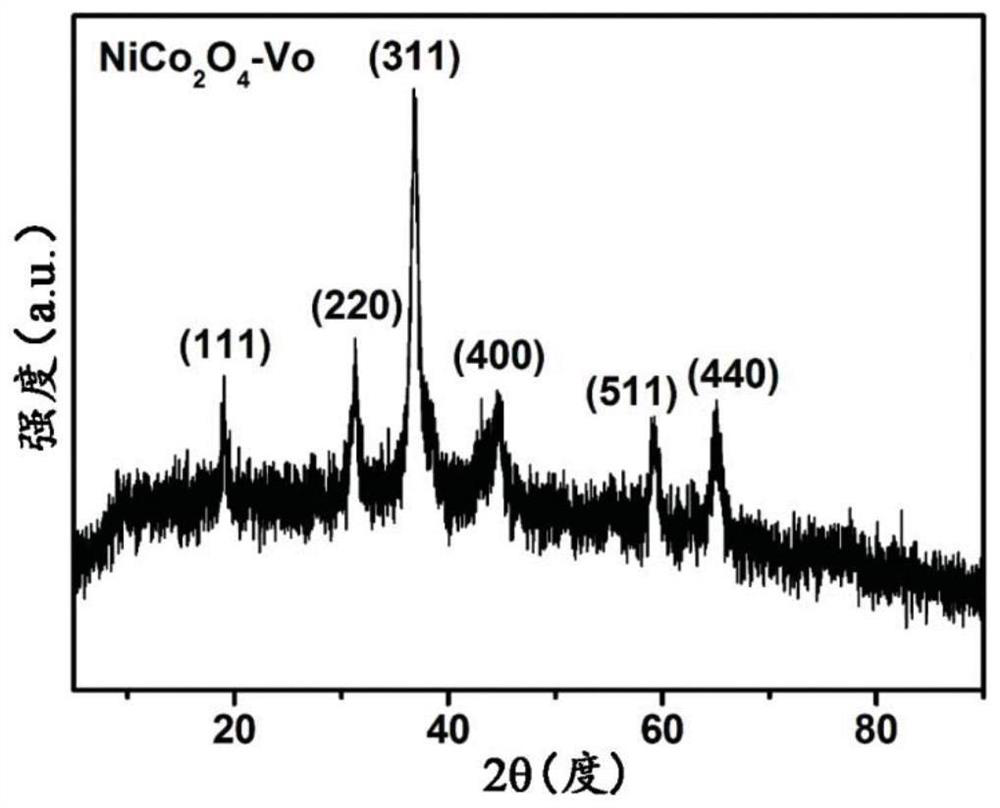

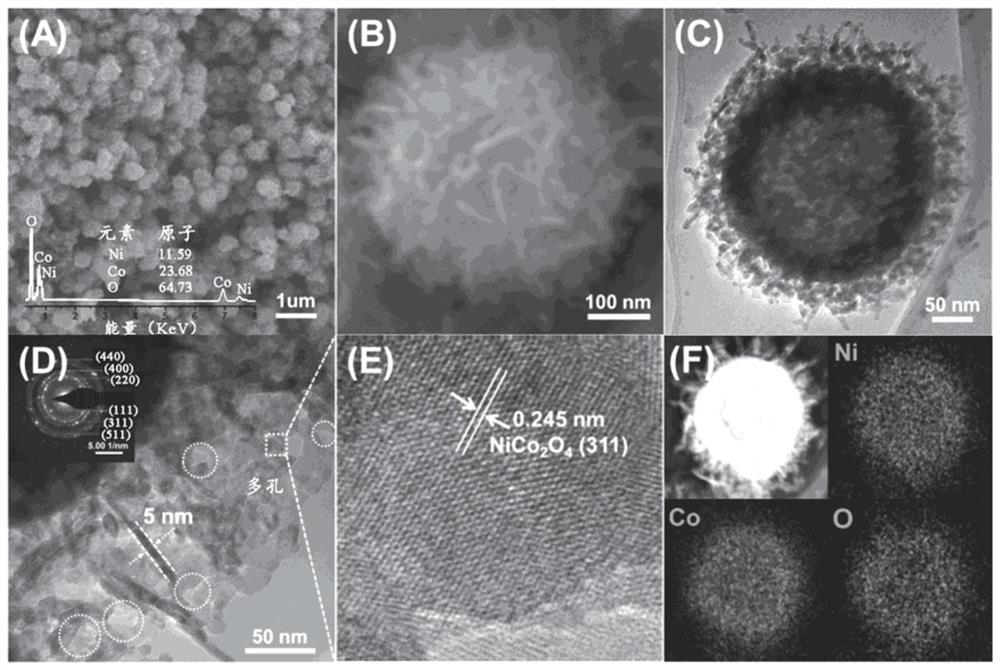

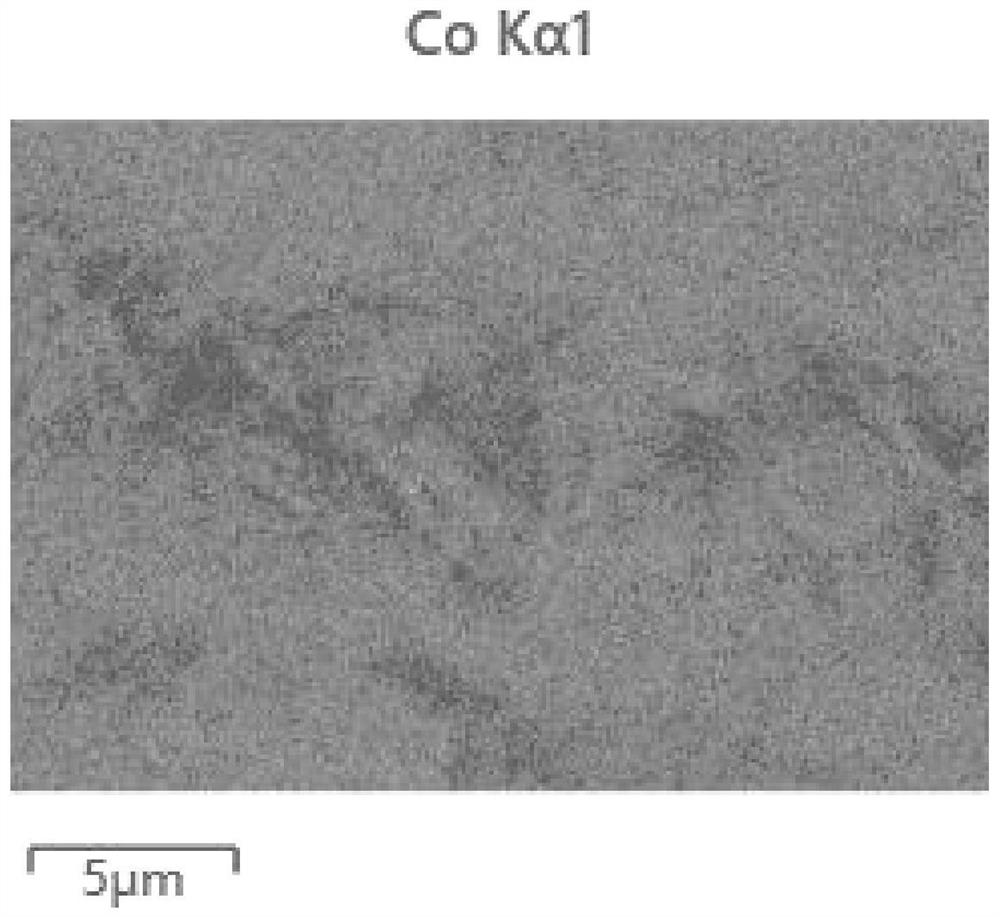

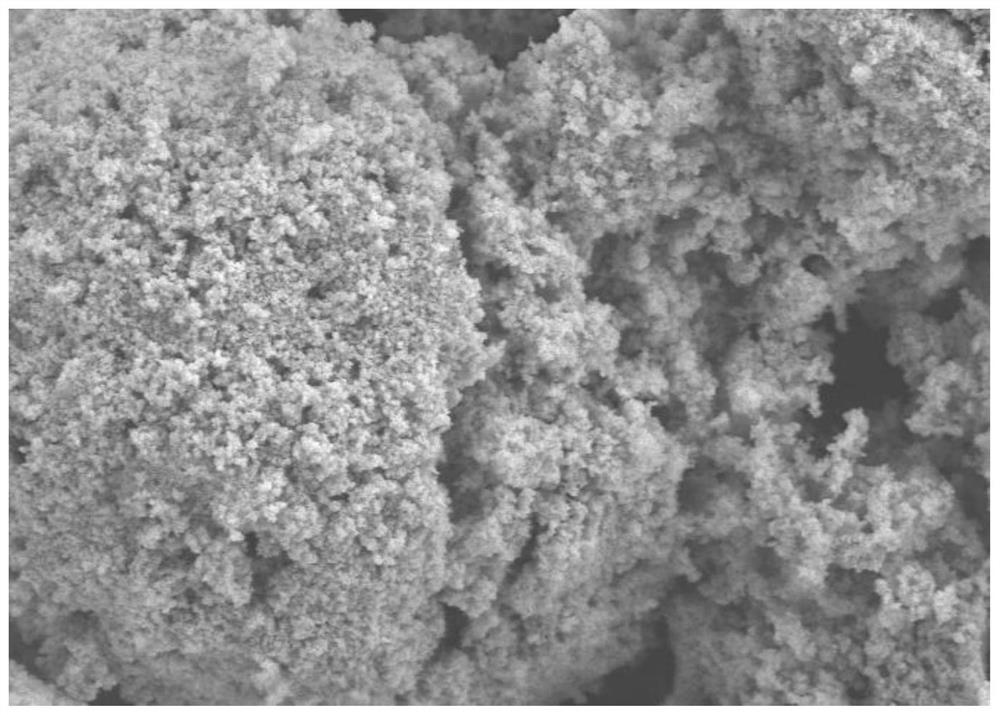

Nickel cobaltate nano material as well as preparation method and application thereof

ActiveCN112939097APoor circulationLow cost of preparationCell electrodesNanotechnologyNickelOxygen rich

The invention discloses a nickel cobaltate nano material as well as a preparation method and application thereof. The nano material is spherical, is in the diameter of 0.1-1 mu m, has a porous and hollow structure, has oxygen-rich vacancy defects and has the specific surface area of 20-70 m < 2 > / g. The nickel cobaltate nano material is high in activity and low in preparation cost, the preparation method is simple and easy to implement, large-scale batch preparation can be achieved, and the nickel cobaltate nano material has good industrial application prospects.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

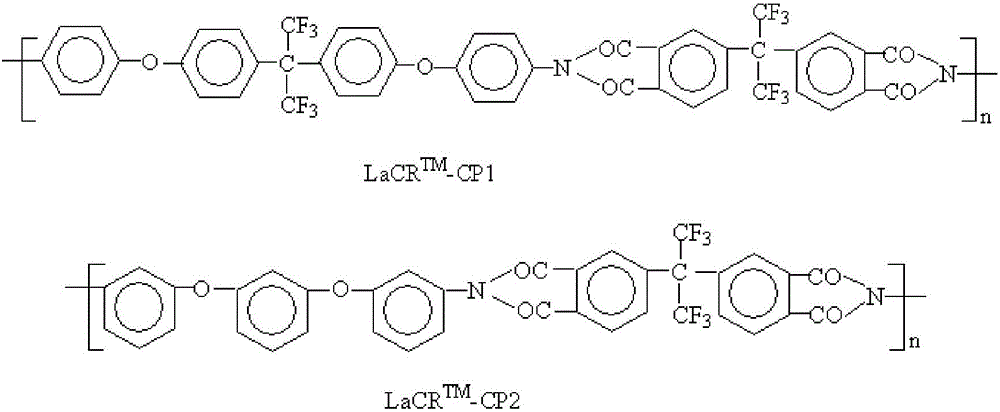

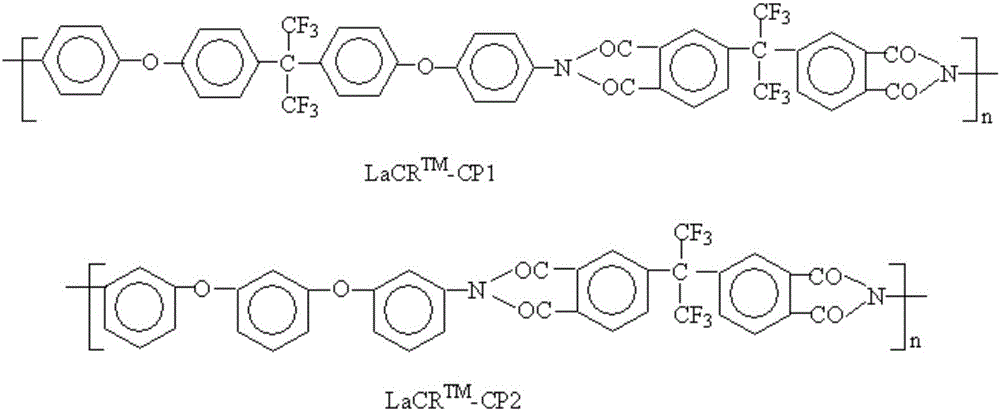

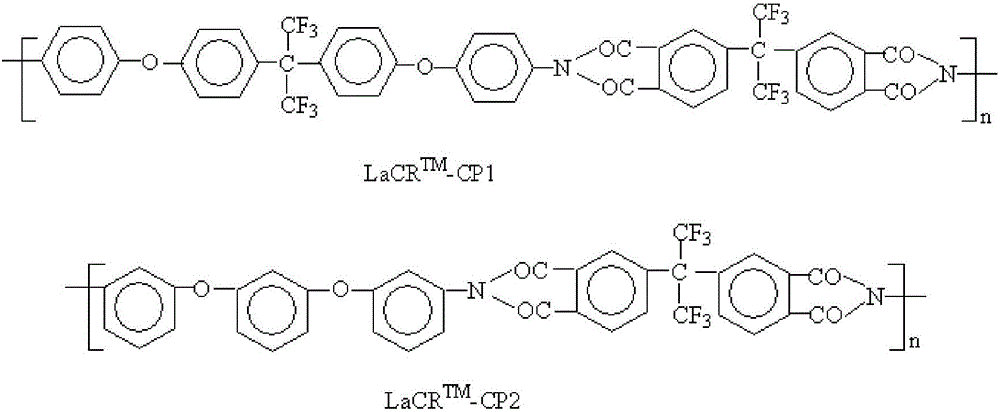

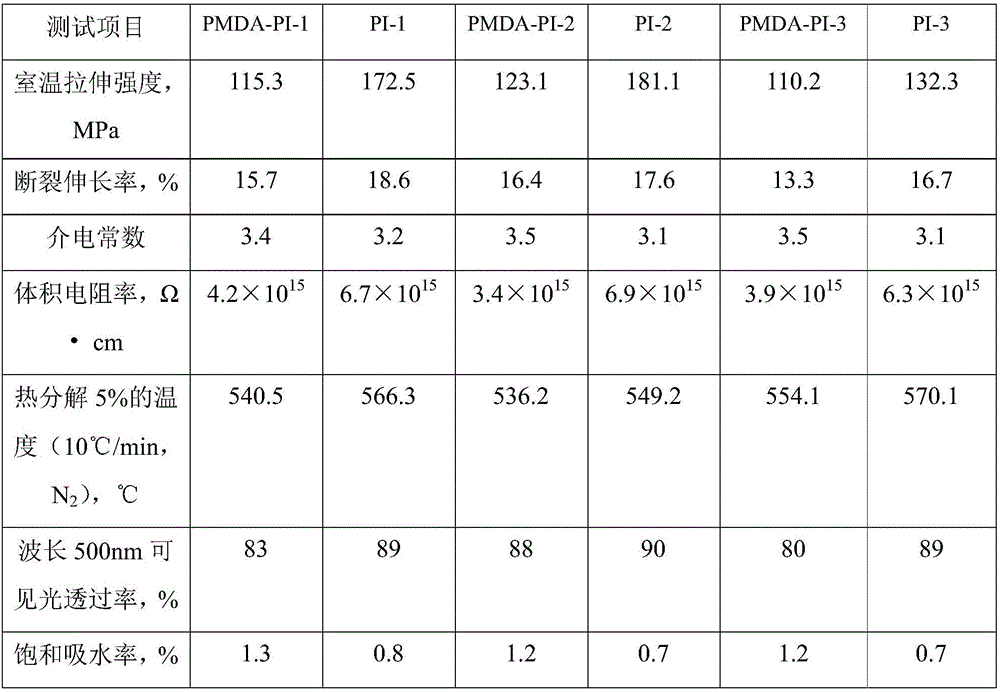

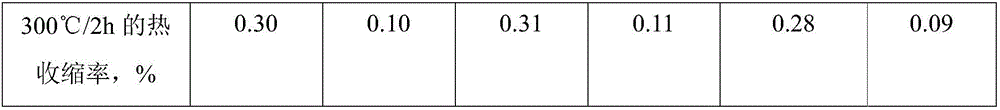

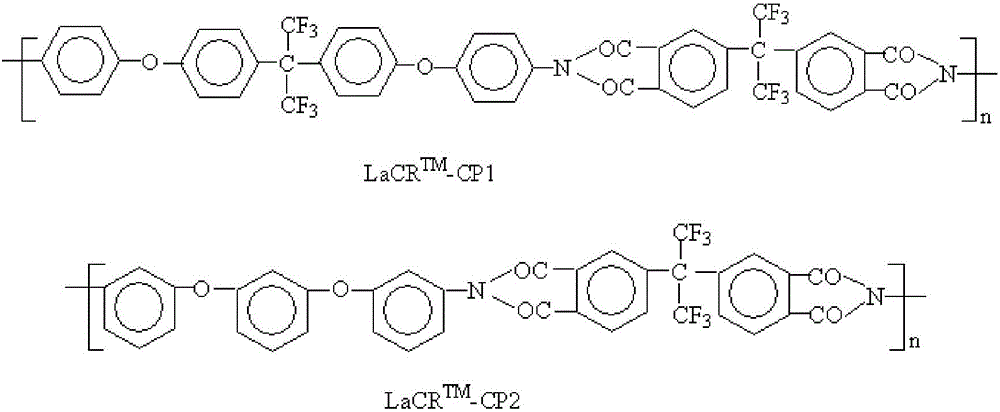

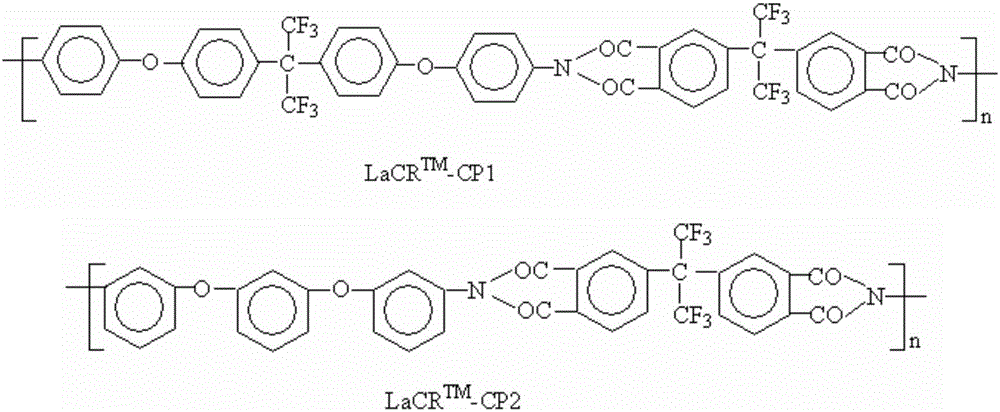

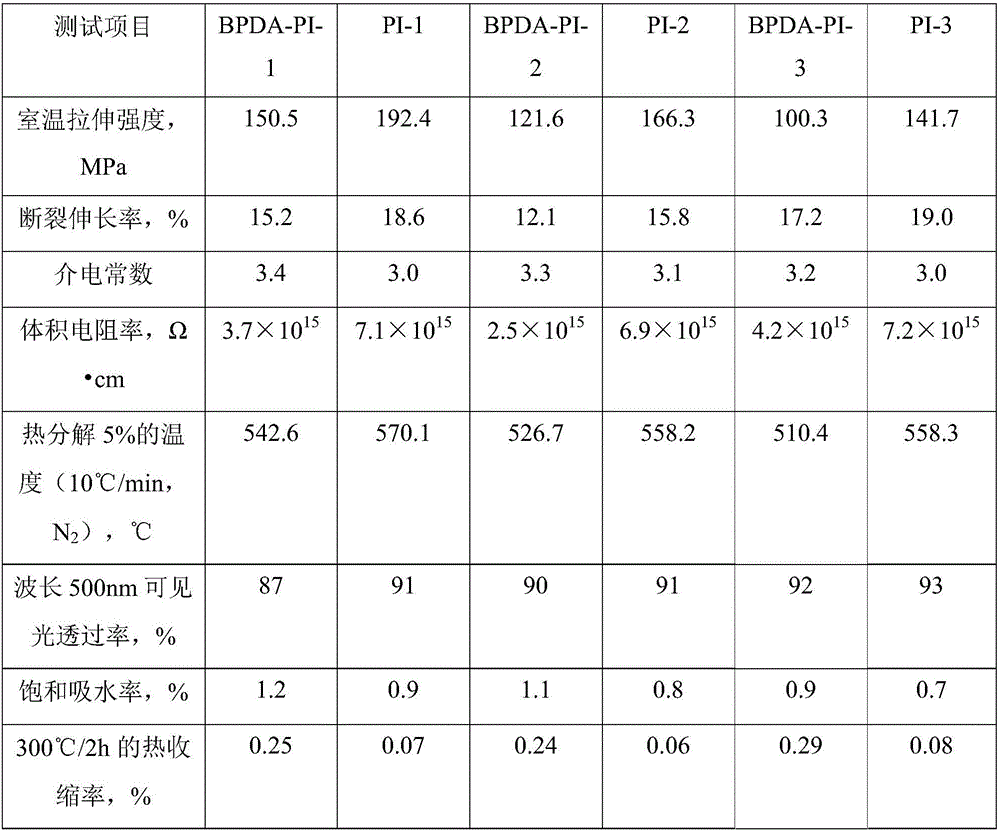

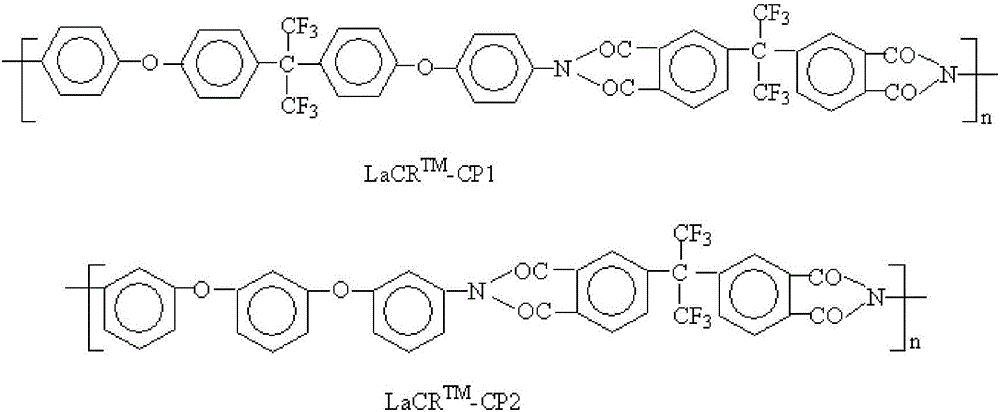

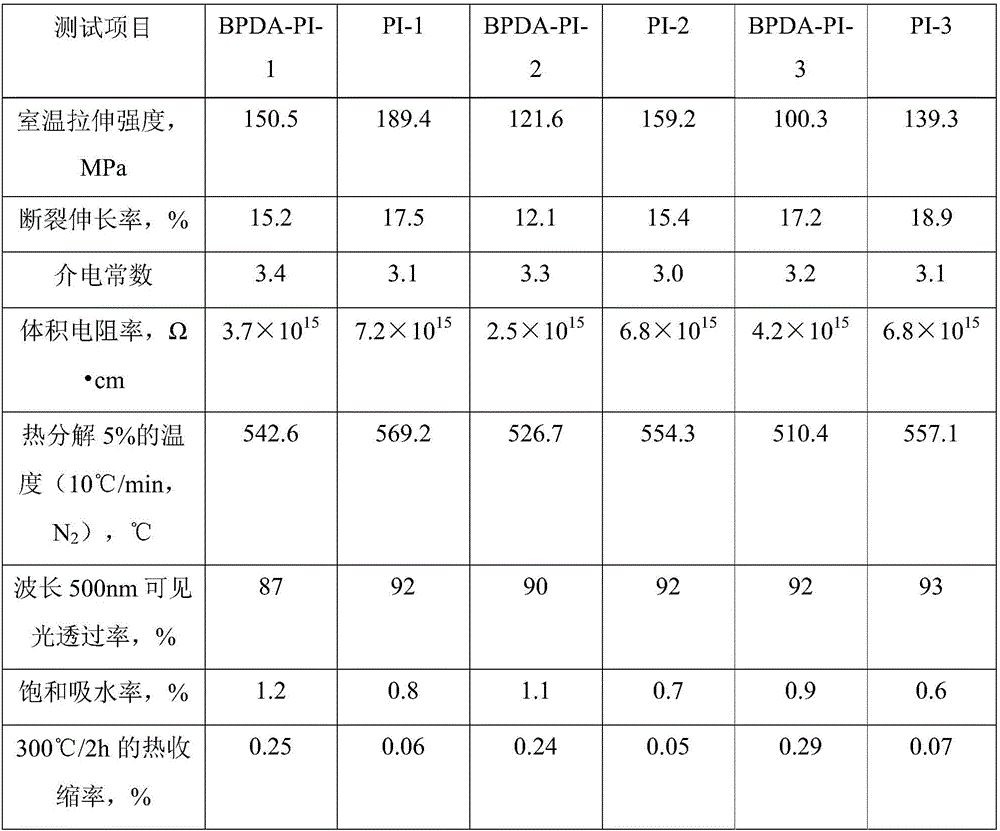

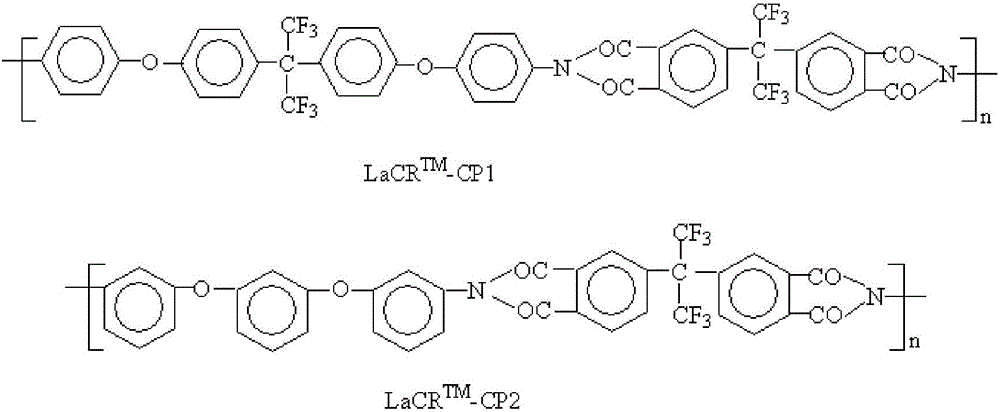

6FDA-type fluorine-containing branched polyimide resin film and preparation method thereof

The invention relates to a 6FDA-type fluorine-containing branched polyimide resin film and a preparation method thereof. In the raw materials of the film, the mass ratio of BDAPFP to 6FDA-type linear polyamide acid resin is 1:(100-800). The preparation method comprises the following steps: mixing eldest aromatic binary amine with a strong-polar aprotic organic solvent, stirring at room temperature, and cooling to a temperature below 5 DEG C; adding 6FDA, stirring, and reacting for 1-6 hours at 5-10 DEG C to obtain a 6FDA-type fluorine-containing branched polyimide resin solution; and mixing the resin solution with BDAPFP at room temperature, stirring, forming a film, heating and increasing the temperature, performing dehydration and thermal imidization reaction, cooling and removing the mold. The method has the advantages of mild reaction conditions, simple operation, low cost and environmental friendliness, is favorable for implementing industrial large-scale production, and can be applied to high-tech fields, including flexible solar cells, space telescopes, large generator main insulation materials, electromagnetic wire lapped electrical insulation materials, flexible copper-clad plates and the like.

Owner:DONGHUA UNIV +1

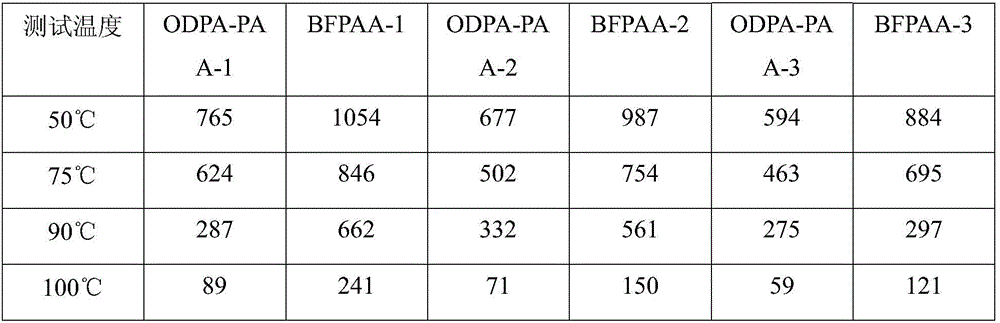

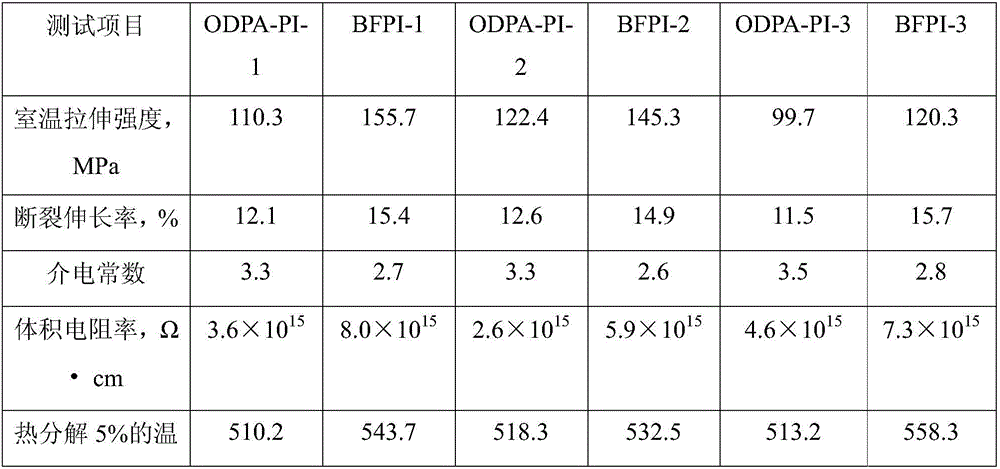

ODPA-type fluorine-containing branched polyimide resin film and preparation method thereof

The invention relates to an ODPA-type fluorine-containing branched polyimide resin film and a preparation method thereof. The mass ratio of BDAPFP and ODPA-type linear polyamide acids resins in the raw materials of the film is 1:100-800. The preparation method comprises the following steps: aromatic dicarboxylic primary amine and an aprotic organic solvent having strong polarity are mixed, a mixture is stirred under room temperature and then is cooled to the temperature of below 5 DEG C, ODPA is added and stirred, then is reacted for 1-6 hours at the temperature of 5-10 DEG C to obtain an ODPA-type polyamide acid resin solution; the resin solution and BDAPFP are mixed at room temperature, the mixture is stirred and is subjected to film forming, the material is heated, then is subjected to dehydration and thermal imidization, and the material is cooled and demoulded to obtain the product. The method has the advantages of mild condition, simple operation, low cost, and environment friendliness, is in favor of realizing industrial scale production, and can be used in the field of high technology such as flexible solar energy cells, space telescopes, large generator winding insulation, insulated wire lapping electrical insulating materials, and flexible copper-clad plates.

Owner:DONGHUA UNIV +1

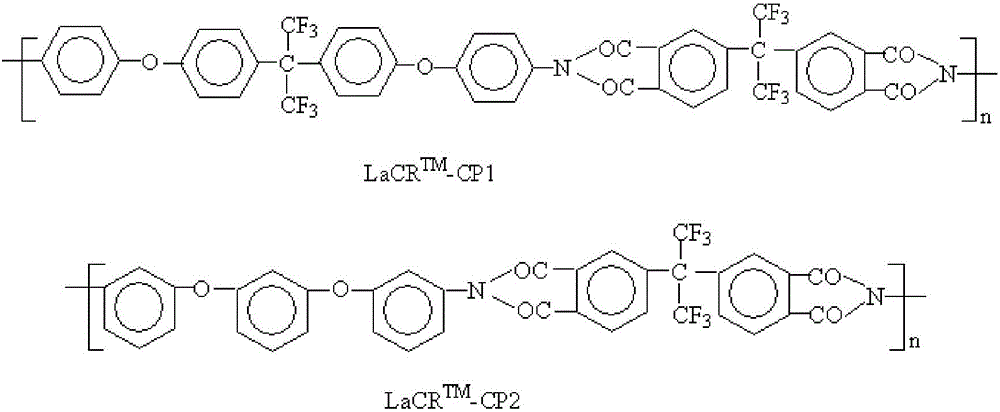

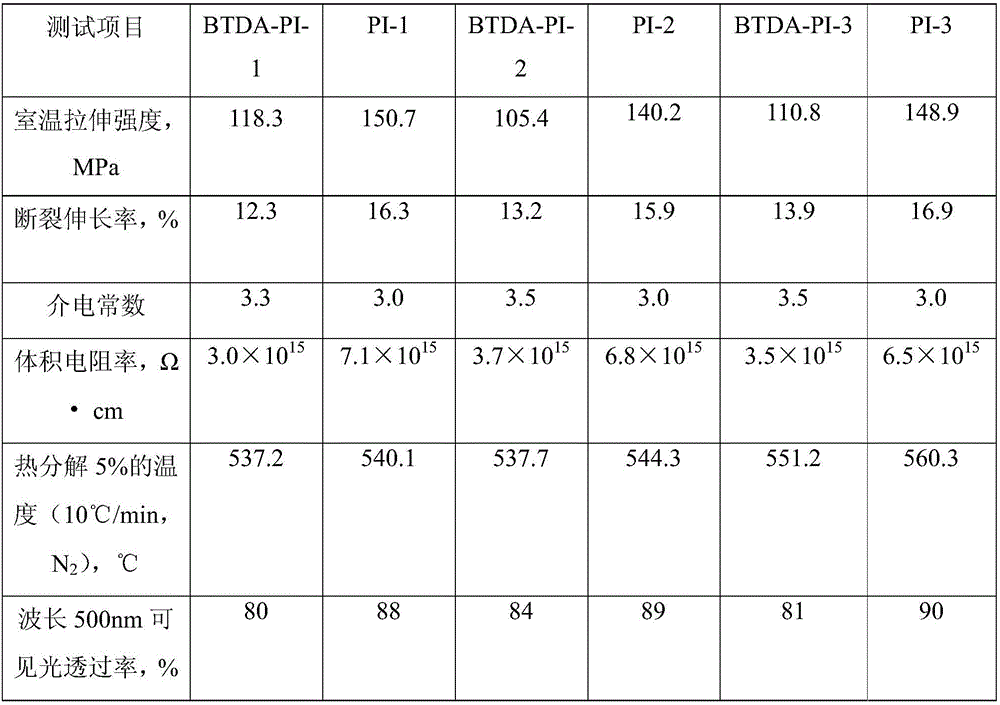

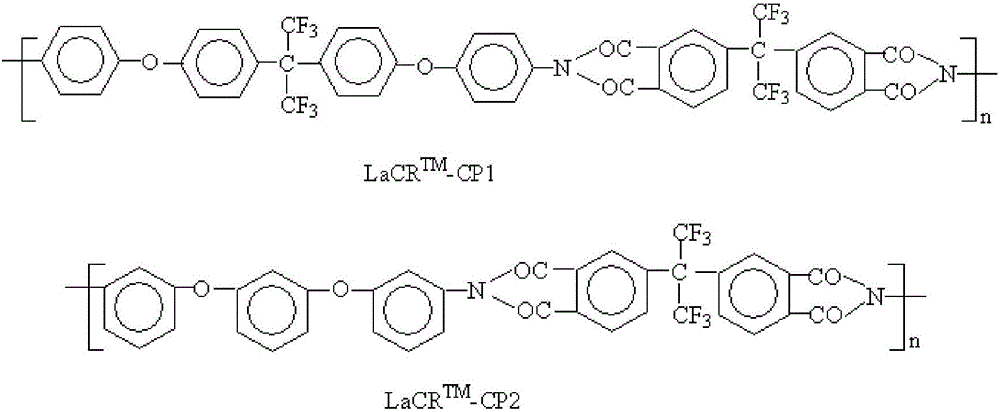

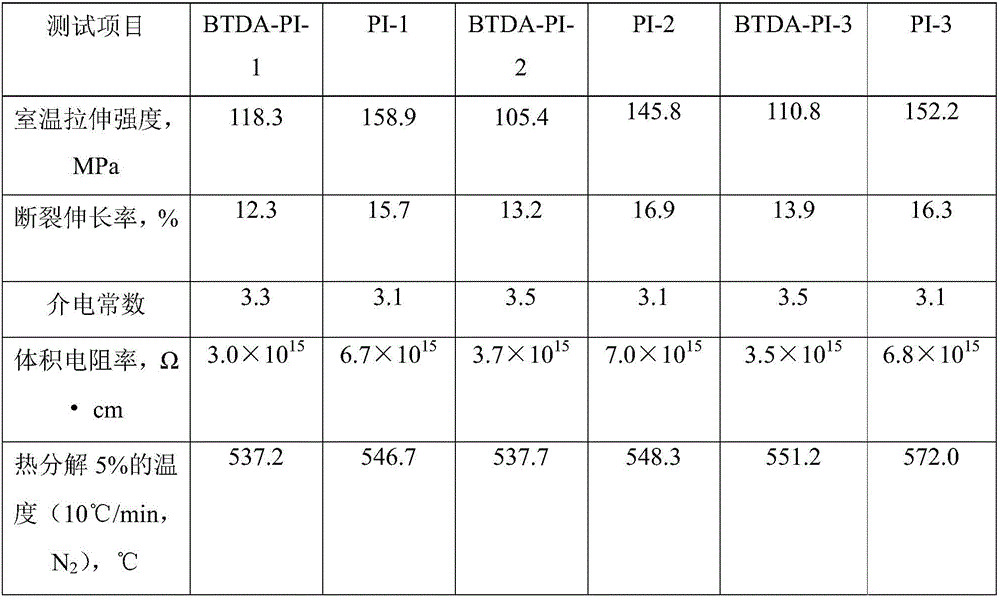

BTDA type BDADTBHQ branched polyimide resin thin film and preparation method thereof

The invention relates to a BTDA type BDADTBHQ branched polyimide resin thin film and a preparation method thereof. The mass ratio of BDADTBHQ to BTDA type linear polyamide acid resin in raw materials of the film is 1 to (100-800). The preparation method comprises the following steps: mixing aromatic di-primary amine with a strongly polar non-proton organic solvent, stirring at the room temperature, cooling to below 5 DEG C, adding BTDA, stirring, and reacting at the temperature of 5 to 10 DEG C for 1 to 6 hours to obtain a BTDA type polyamide acid resin solution; mixing the resin solution with the BDADTBHQ at the room temperature, stirring, forming a film, heating, carrying out a dehydration hot amination reaction, cooling, and demolding to obtain the product. The method has the advantages of mild reaction conditions, easiness in operation, low cost and environmental friendliness, is beneficial to the realization of industrialized scale production, and can be applied in the fields of flexible solar cells, space telescopes, main insulators of large motors, electrical insulating materials wrapping electromagnetic wires, flexible copper clad laminates and the like.

Owner:DONGHUA UNIV +1

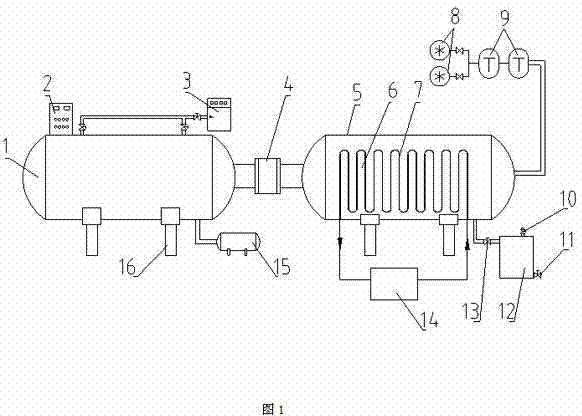

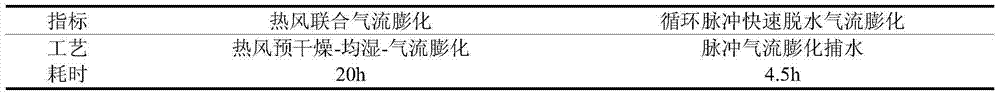

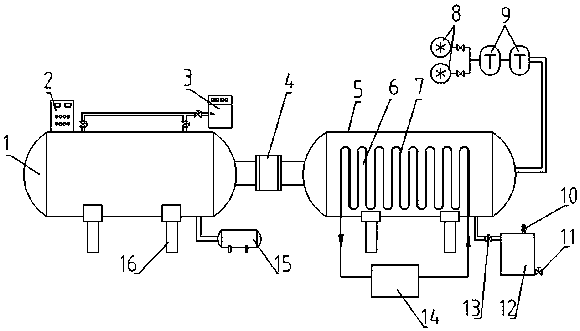

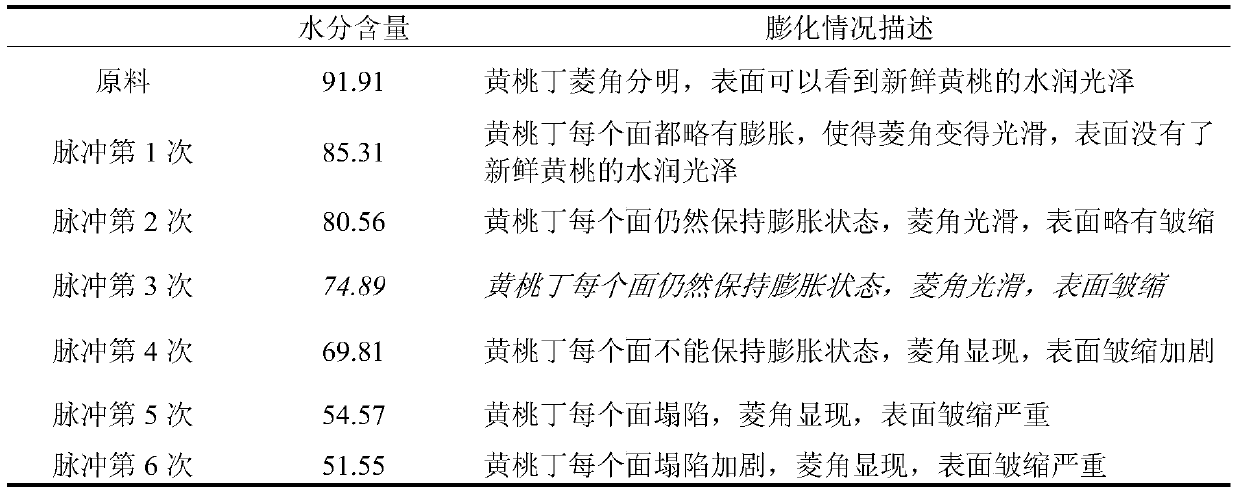

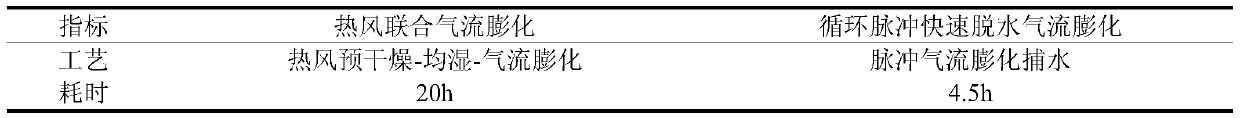

Rapid dehydration type pneumatic-puffing equipment

ActiveCN104719789AImprove drying rateReduce workloadFood shapingFood preparationLiquid waterPulp and paper industry

The invention relates to puffing equipment, in particular to rapid dehydration type pneumatic-puffing equipment. A water catcher is arranged in a vacuum tank of the equipment, wherein a condenser pipe of the water catcher is paved in the vacuum tank in an S shape, and is connected with the water catcher through a snuffle valve below the vacuum tank; a drain valve is arranged at the lower end of the water catcher and is used for discharging condensate water in the water catcher. When the rapid dehydration type pneumatic-puffing equipment works, a lot of flashing hot steam generated by a lot of materials in the puffing tank due to rapid pressure relief penetrates through the water catcher, the hot steam is rapidly cooled and condensed into water due to fully heat exchange between the flashing hot steam and a refrigerating coil, is collected into a water collector through a pipeline, and then is discharged out of the equipment; a lot of hot steam is converted into liquid water and then is discharged by the water catcher in the vacuum tank in a vacuum state; the vacuum degree required for puffing and drying is kept; the workload of a vacuum pump assembly at the rear end is reduced; the drying rate of materials is greatly improved; the quality of a dry product is improved; and achievement of industrial large-scale production employing a pneumatic-puffing technology is facilitated.

Owner:JIANGSU ACAD OF AGRI SCI

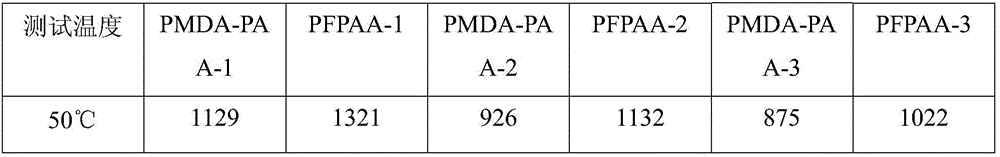

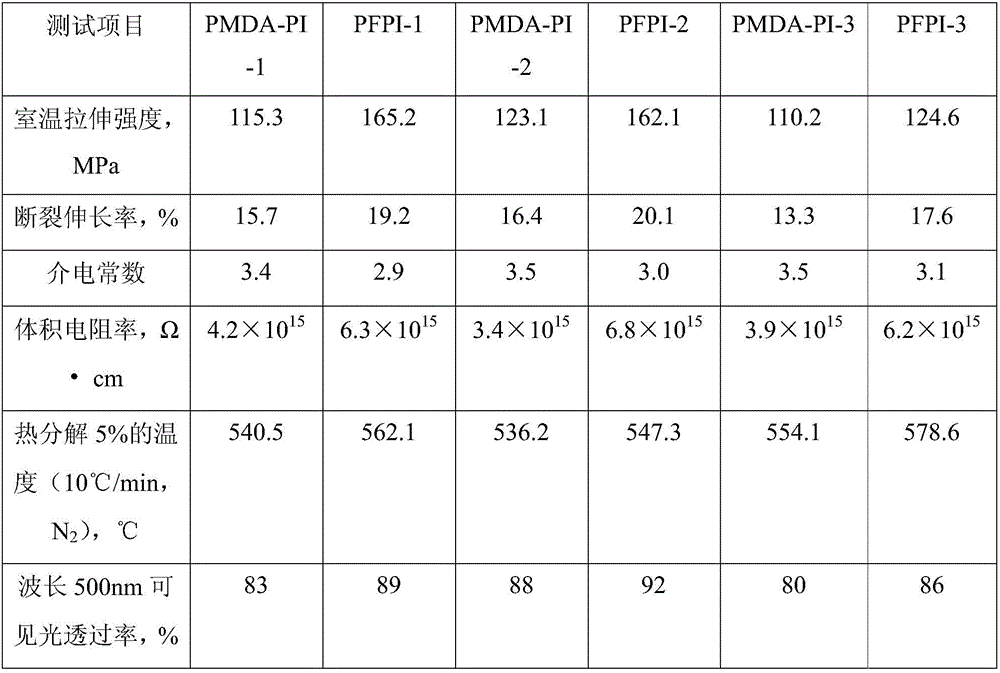

PMDA type fluorine-containing branched polyimide resin film and preparation method thereof

The invention relates to a PMDA type fluorine-containing branched polyimide resin film and preparation method thereof. In the raw materials of the film, BDAPFP and PMDA linear polyamic acid resin are in a mass ratio of 1:100-800. The preparation method comprises the steps of: mixing aromatic binary primary amine with a strong polar non-protonic organic solvent, conducting stirring at room temperature, performing cooling to a temperature below 5DEG C, adding PMDA, conducting stirring, and carrying out reaction at 5DEG C-10DEG C for 1-6h to obtain a PMDA type polyamic acid resin solution; mixing the resin solution with BDAPFP at room temperature, conducting stirring, film-forming and heating, carrying out dehydration thermal imidization reaction, and performing cooling and demoulding, thus obtaining the PMDA type fluorine-containing branched polyimide resin film. The method provided by the invention has the advantages of mild reaction conditions, simple operation, low cost, and environmental friendliness, is conducive to realizing large-scale industrial production. And the PMDA type fluorine-containing branched polyimide resin film can be applied to flexible solar cells, space telescopes, large generator main insulation, electromagnetic wire wrapped electrical insulating materials, flexible copper-clad plates and other high-tech fields.

Owner:DONGHUA UNIV +1

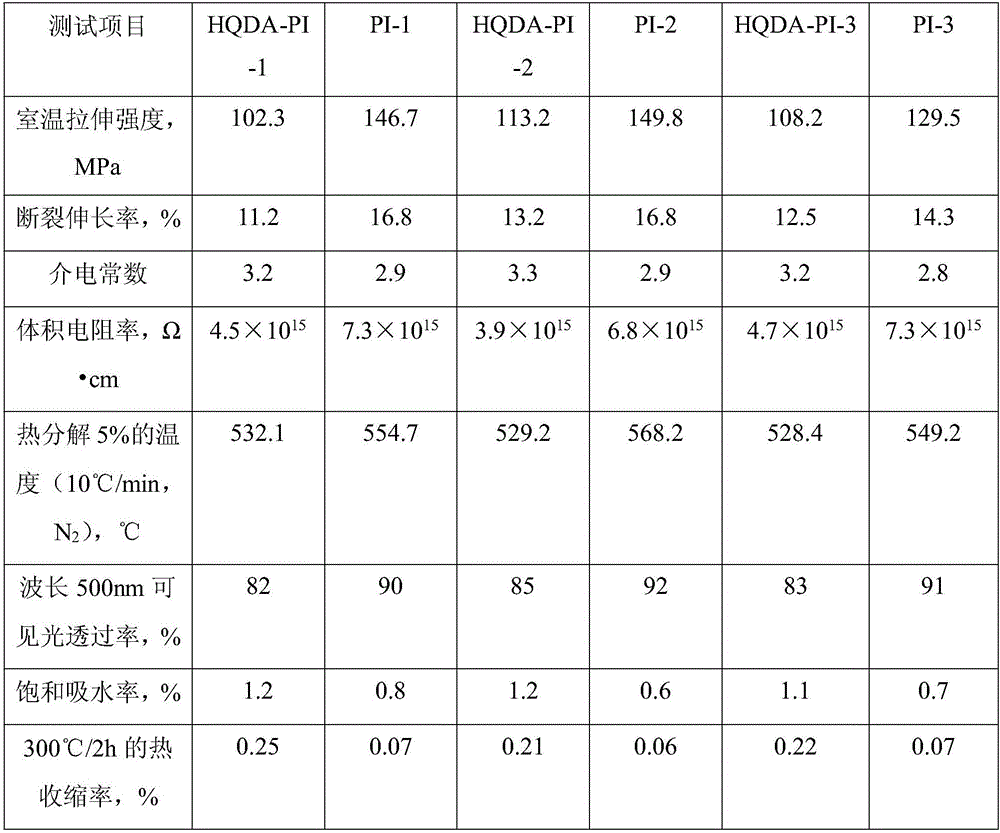

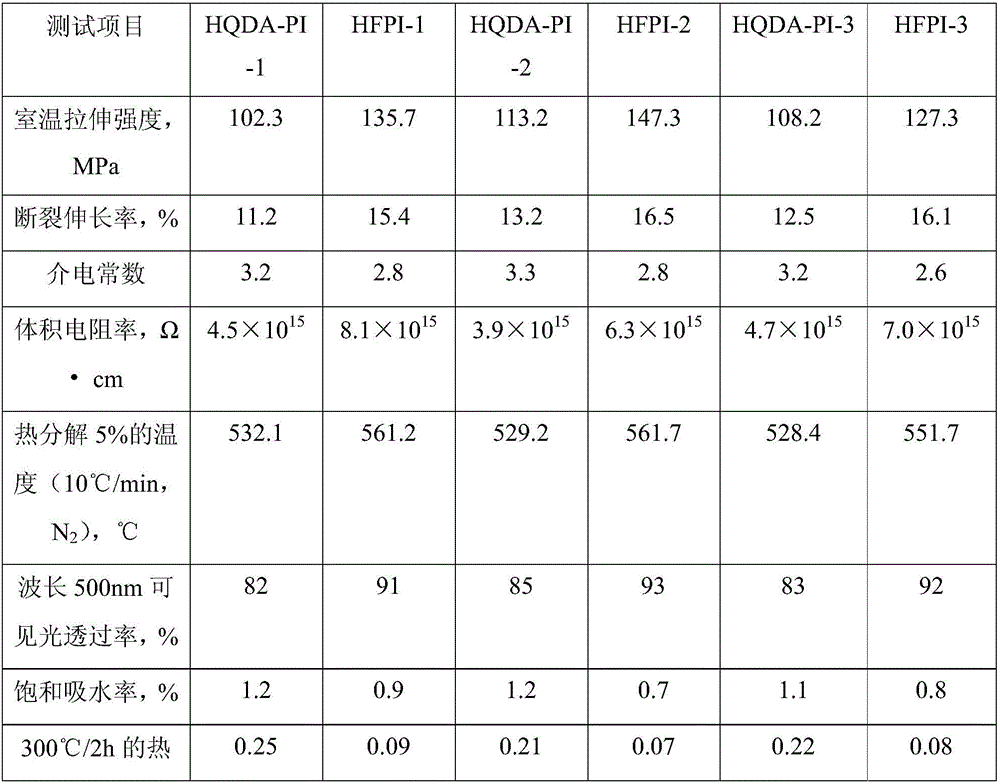

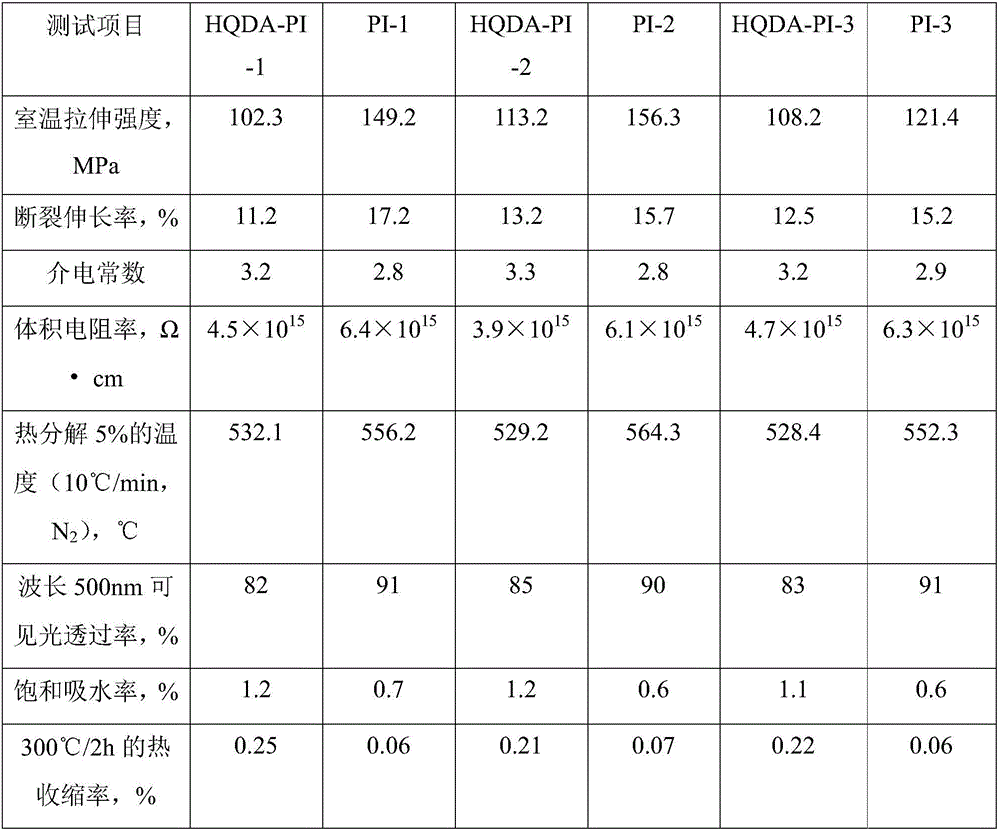

HQDA type bisphenol A tetramine branched polyimide resin film and preparation method thereof

The invention relates to an HQDA type bisphenol A tetramine branched polyimide resin film and a preparation method thereof. A mass ratio of BDAPP type linear polyimide resin to HQDA type linear polyimide resin in raw materials of the film is 1 to (100-800). The preparation method comprises the following steps: mixing aromatic binary primary amine with a strong-polarity aprotic organic solvent to obtain a mixture, stirring the mixture at the room temperature, cooling the mixture to a temperature lower than 5 DEG C, adding HQDA into the mixture, stirring, and reacting for 1-6 hours at a temperature ranging from 5 DEG C to 10 DEG C to obtain an HQDA type polyimide resin solution; and mixing the resin solution with BDAPP at the room temperature to obtain a mixed solution, stirring the mixed solution, enabling the mixed solution to form a film, heating the film, carrying out dehydration thermal imidization reaction on the film, cooling the film, and de-molding the film to obtain the HQDA type bisphenol A tetramine branched polyimide resin film. The preparation method is gentle in reaction condition, is simple to operate, is low in cost, is environmentally friendly, is beneficial for realizing industrial large-scale production, and can be applied to the high-tech fields such as flexible solar cells, space telescopes, large generator main insulation, electromagnetic wire wrapping electrical insulating materials, flexible copper-coated foil plates and the like.

Owner:DONGHUA UNIV +1

Alkali-activated slag mortar mixed material and preparation method thereof

The invention belongs to the technical field of cement-based composite materials, and particularly relates to an alkali-activated slag mortar mixed material and a preparation method thereof. The alkali-activated slag mortar mixed material comprises alkali-activated slag mortar and a mixture of rigid fibers and tetrasodium hydroxyethylidene diphosphonate. The rigid fibers have the effects of crack resistance, reinforcement and toughening, and are beneficial to improving the mechanical properties of the alkali-activated slag mortar. Meanwhile, the tetrasodium hydroxyethylidene diphosphonate can delay the setting time of the alkali-activated slag mortar and improve the flowing property and rheological property of the alkali-activated slag mortar, and the improvement of the rheological property can further improve the distribution and orientation of the rigid fibers in the alkali-activated slag mortar, so that the promotion effect of the rigid fibers is better exerted. Therefore, the alkali-activated slag mortar mixed material provided by the invention has good working performance and mechanical properties, can meet the requirements of actual construction and the requirements on material strength, and has a good application prospect.

Owner:SHENZHEN UNIV

BPDA type BDATHQ branched polyamide resin film and preparation method thereof

The invention relates to a BPDA type BDATHQ branched polyamide resin film and a preparation method thereof. In raw materials of the film, the mass ratio of BDATHQ and BPDA type linear polyamic acid resins is 1:(100-800). The preparation method comprises the following steps: mixing aromatic dual primary amine with strongly polar aprotic organic solvent, stirring at room temperature, cooling to 5 DEG C or below, adding BPDA, stirring, and reacting at 5-10 DEG C for 1-6 hours to obtain a BPDA type polyamic acid resin solution; and mixing the resin solution with BDATHQ at room temperature, stirring, forming a film, heating, performing dewatering thermal imidization, cooling, and stripping to obtain the final product. The method provided by the invention is mild in reaction conditions, simple to operate, low in cost and friendly to environment, thereby being beneficial to industrial large-scale production; and the film can be used in the high-tech fields of flexible solar cells, space telescopes, large generator main insulation, magnet wire wrapping electrical insulation materials, flexible copper-clad plates and the like.

Owner:DONGHUA UNIV +1

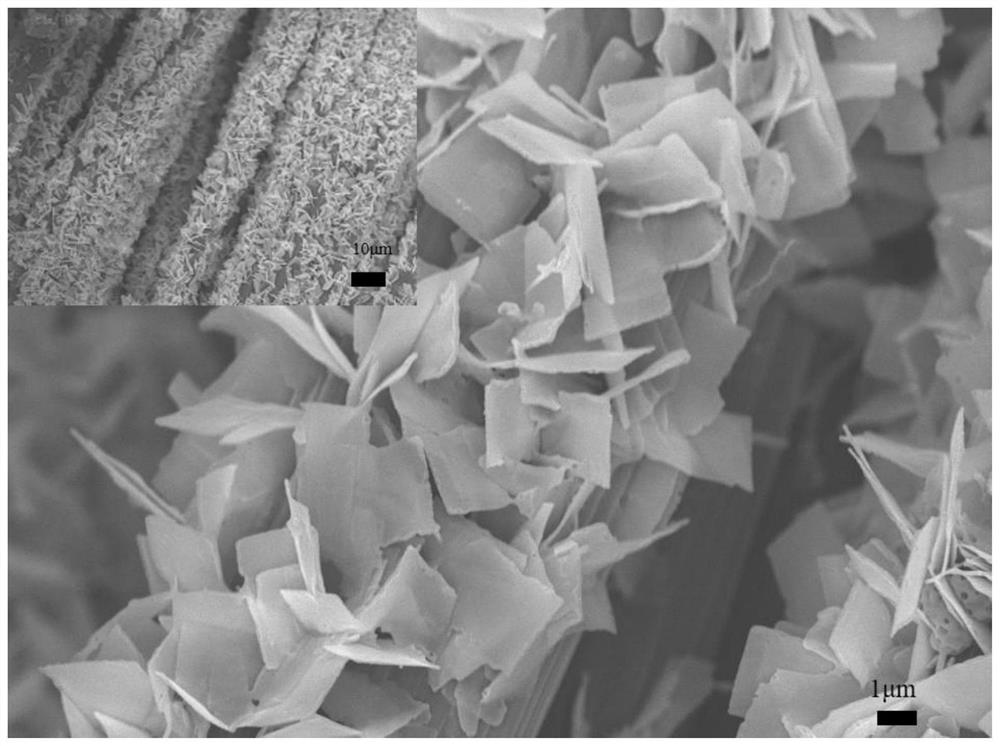

Preparation method of flexible flaky MoPCoP array electrolyzed water catalyst composite material

The invention provides a preparation method of a flexible flaky MoPCoP array electrolyzed water catalyst composite material, relates to the technical field of electrolyzed water, and solves the problem that the HER catalytic activity and stability of an existing electrolyzed water hydrogen evolution catalyst cannot meet actual requirements. The preparation method of the flexible flaky MoPCoP array electrolyzed water catalyst composite material comprises the steps of 1) preparing a carbon cloth loaded cobalt nano material, specifically, preparing Co (NO3) 2.6 H2O and CH4N2O according to a certain molar volume ratio, adding Co (NO3) 2.6 H2O into 40 ml of deionized water, carrying out ultrasonic treatment for 30 minutes, uniformly mixing, then adding CH4N2O, and continuing ultrasonic treatment for 30 minutes; and 2) putting the mixed solution obtained by ultrasonic treatment in the step 1) and carbon cloth into a reaction kettle together, and preserving heat in the reaction kettle at the heat preservation temperature of 100 DEG C for 12 hours. The prepared flexible flaky MoPCoP array electrolyzed water catalyst composite material is high in catalytic activity and good in stability, and the preparation method is simple, good in repeatability and beneficial to industrial large-scale production.

Owner:CHANGCHUN UNIV OF TECH

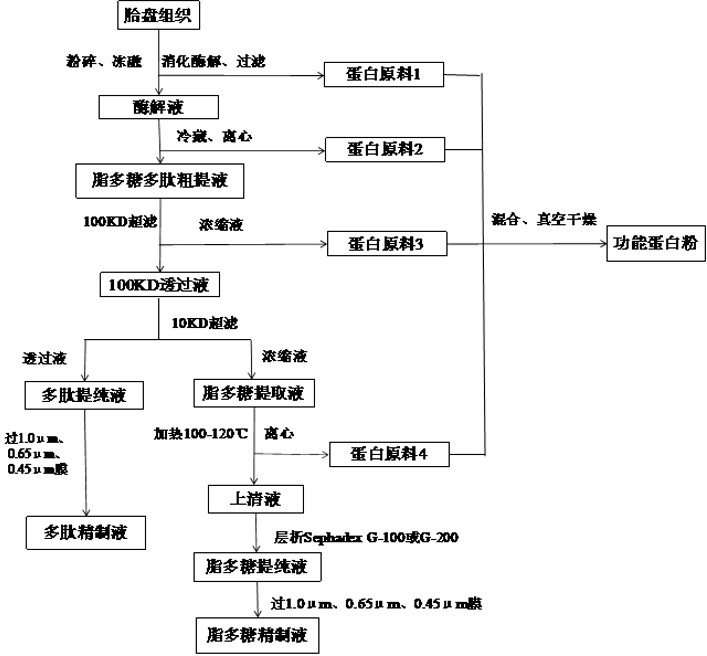

Placental lipopolysaccharide-polypeptide dual immunopotentiator and preparation method thereof

ActiveCN106729601BStrong immune functionImprove immunityOrganic active ingredientsHydrolysed protein ingredientsBiotechnologyPolythylene glycol

The invention relates to a placental lipopolysaccharide-polypeptide bivalent immunoenhancer and a preparation method thereof. Lipopolysaccharide and polypeptide which are extracted from animal placentas (pig, cattle, sheep and the like) are taken as main raw materials, and the main raw materials are combined with auxiliary materials such as polyethylene glycol and xylitol so as to be prepared into an oral preparation. A formula of the placental lipopolysaccharide-polypeptide bivalent immunoenhancer is that every 100mL of the oral preparation contains 5-30mg of placental lipopolysaccharide, 0.1-1.0g of polypeptide, 3-10g of polyethylene glycol and 1-15g of xylitol. The placental lipopolysaccharide-polypeptide bivalent immunoenhancer provided by the invention has the advantages that a co-production technology is adopted, the modern biological process integration technology and a green biochemical extraction technology are applied, animal placental lipopolysaccharide and placental peptide are perfectly combined, synergistic effects are achieved, immunologic functions of an organism on multiple bacteria and viruses are enhanced, and the placental lipopolysaccharide-polypeptide bivalent immunoenhancer has better curative effects on chronic bronchitis, bronchial asthma and cold prevention of human and animals respectively and can be widely applied to industries of medical treatment as well as prevention and health care on the human and animals. A production process of the immunoenhancer product is pollution-free, the three wastes are not produced, energy conservation and environmental protection are realized, the production cost is low, and economic benefits are obvious.

Owner:王景仙

PMDA type bisphenol A tetramine branched polyimide resin film and a preparing method thereof

The invention relates to PMDA type bisphenol A tetramine branched polyimide resin film and a preparing method thereof. The mass ratio of BDAPP and PMDA type linear polyamide acid resin in raw materials of the film is 1:100-800. The preparing method includes mixing an aromatic primary diamine and a strong-polarity aprotic organic solvent, stirring the mixture at room temperature, cooling the mixture to 5 DGE C or below, adding PMDA into the mixture, stirring the mixture, reacting the mixture at 5-10 DGE C for 1-6 h to obtain a PMDA type polyamide acid resin solution, mixing the resin solution with the BDAPP at room temperature, stirring the mixture, forming film, heating the product to raise the temperature to perform dehydration thermal imidization, cooling the product and stripping the film. According to the method, reaction conditions are mild, operation is simple, the cost is low, and the method is environmentally friendly and can achieve industrial large-scale production. The film can be applied in high-tech fields, such as flexible solar cells, space telescopes, large motor main insulation, electromagnetic wire wrapping electrically-insulating materials and flexible copper-clad plates.

Owner:DONGHUA UNIV +1

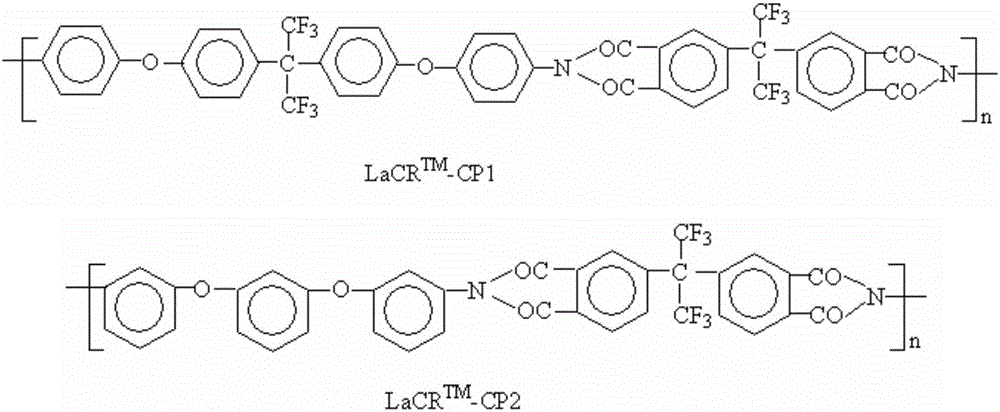

BPADA type BDATHQ branched polyimide resin thin film and preparation method thereof

The invention relates to a BPADA type BDATHQ branched polyimide resin thin film and a preparation method thereof. The thin film comprises raw materials of BDATHQ and BPADA type linear polyamide acid resin with a mass ratio of 1: (100-800). The preparation method comprises the following steps: mixing aromatic primary diamine and a strong polar aprotic organic solvent, carrying out stirring at room temperature, carrying out cooling to 5 DEG C or below, adding BPADA, carrying out stirring, and carrying out a reaction at 5 DEG C to 10 DEG C for 1 to 6 h so as to obtain a BPADA type polyamide acid resin solution; mixing the resin solution and BDATHQ at room temperature, carrying out stirring, forming a film, carrying out heating, carrying out dehydration and thermal imidization, carrying out cooling, and carrying out demoulding. The method provided by the invention has the advantages of mild reaction conditions, simple operation, low cost, environmental friendliness, facilitation to realizing industrial large-scale production, and capability of being applied to the high-tech fields of flexible solar cells, space telescopes, large generator winding insulation, electromagnetic wire lapping electrical insulation materials, flexible copper-clad plates, etc.

Owner:DONGHUA UNIV +1

A kind of preparation method of nanoscale indium hydroxide

ActiveCN110156070BReduce generationReduce difficultyGallium/indium/thallium compoundsIndium(III) hydroxideWash water

The invention provides a preparation method of nano-scale indium hydroxide, comprising the following steps: a) passing ammonia gas into an indium nitrate aqueous solution to obtain a precursor slurry; b) washing the precursor slurry, spraying Dry to obtain indium hydroxide powder. The preparation method provided by the invention can reduce the production of ammonium nitrate mother liquor, reduce the washing difficulty and water consumption, reduce the generation of nitrogen-containing wastewater, and reduce the difficulty of wastewater treatment; at the same time, the preparation method of the invention can obtain nano-scale The product reduces the preparation cost, simplifies the operation steps, and reduces the impurities in the slurry, thereby reducing the washing difficulty and washing water consumption; moreover, the obtained product has a small particle size and good uniformity, and does not need to be screened. the preparation process.

Owner:先导薄膜材料(安徽)有限公司

A kind of transition metal phosphide nanomaterial and its preparation method and application

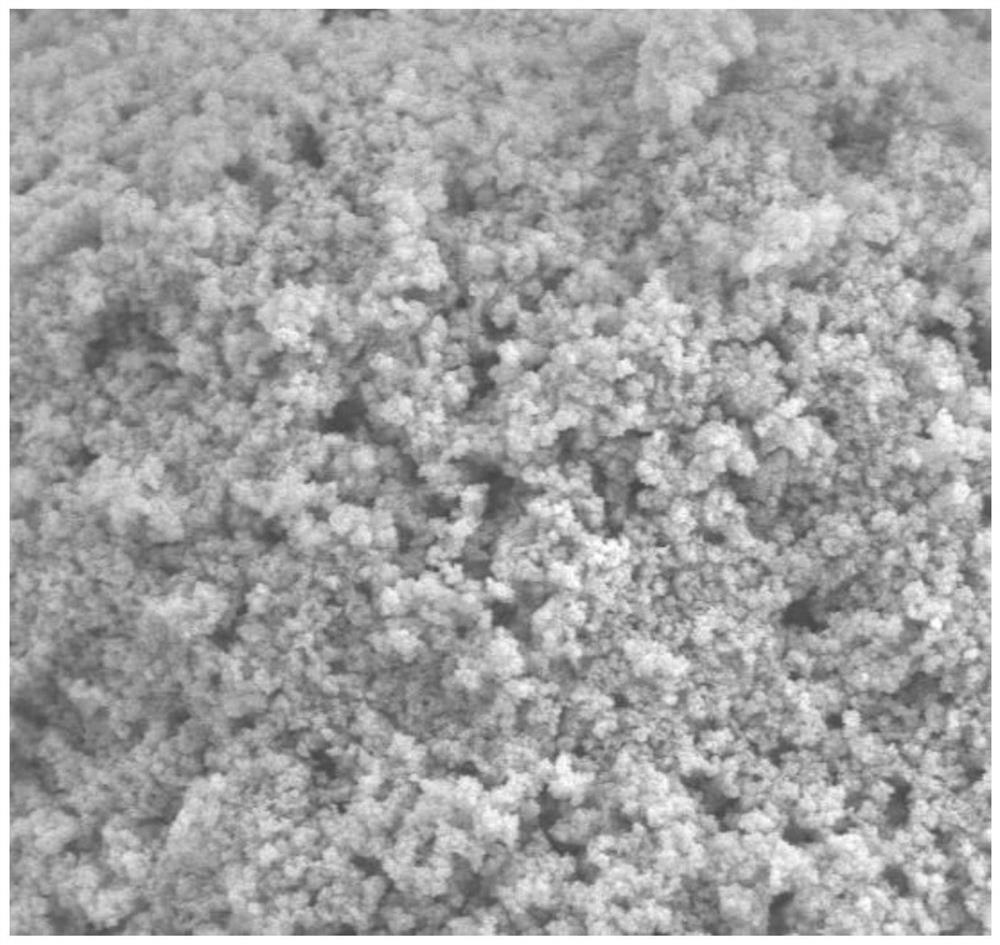

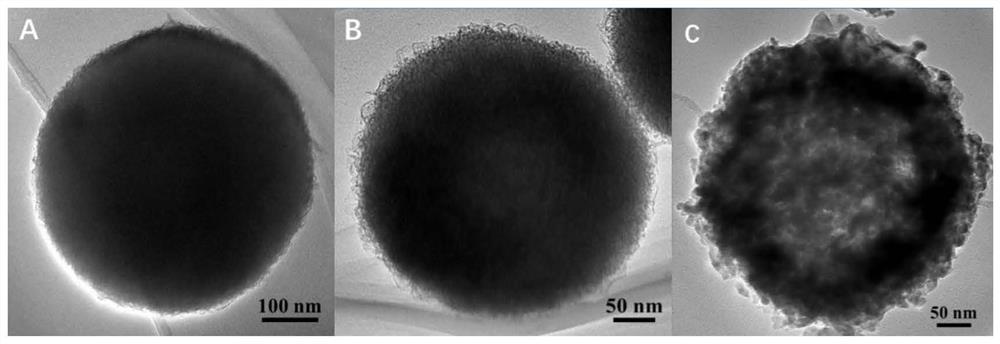

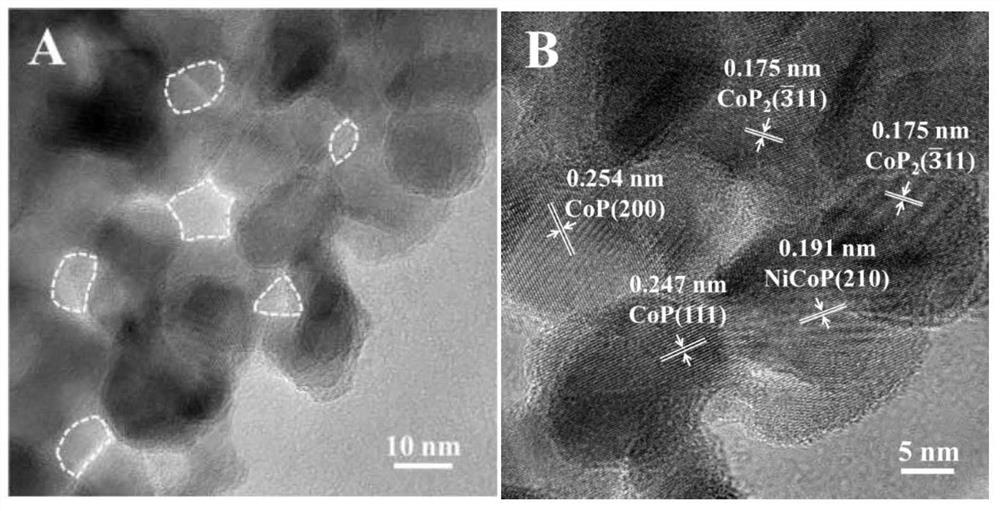

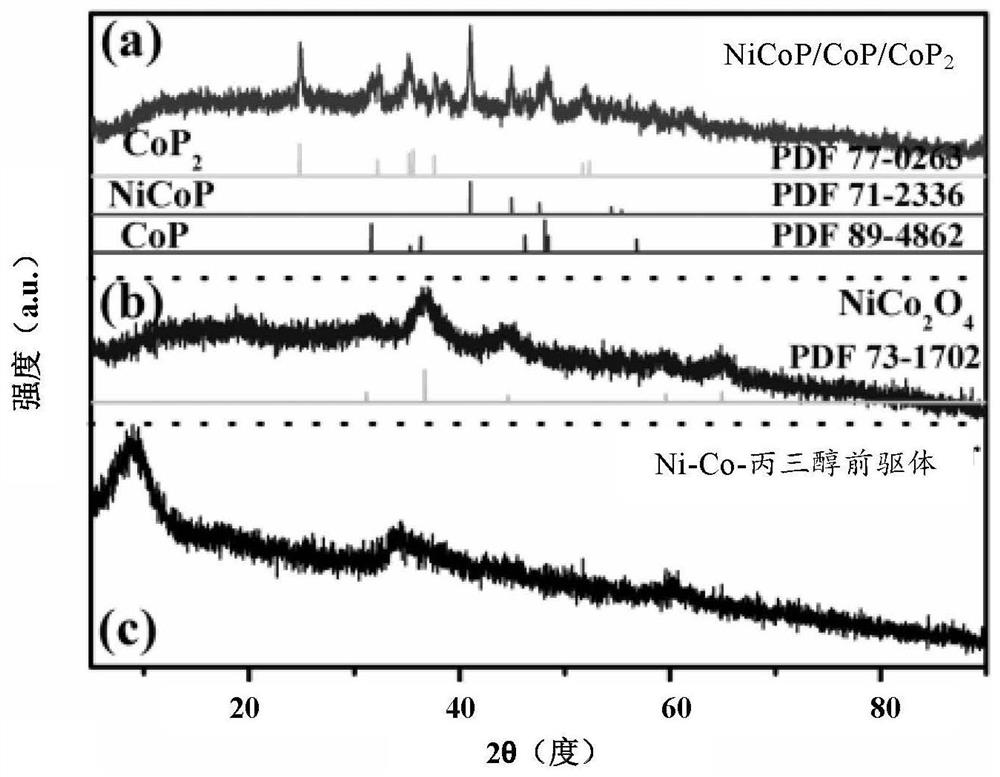

ActiveCN110921641BReduce circulationImprove cycle performanceMaterial nanotechnologyFinal product manufacturePhosphatineIndustrial scale

The invention provides a transition metal phosphide nanomaterial and its preparation method and application. The transition metal phosphide nanomaterial has a porous and hollow structure and contains NiCoP, CoP and CoP 2 , the particles of the transition metal phosphide nanomaterial are spherical, and the sphere wall is composed of small particles with a diameter of 5-20nm, and there are gaps between the particles; the specific surface area of the transition metal phosphide nanomaterial is 20-100m 2 / g. The transition metal phosphide nano material provided by the invention has high catalytic activity and good stability, and the preparation method is simple and repeatable, which is beneficial to realizing industrial scale production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

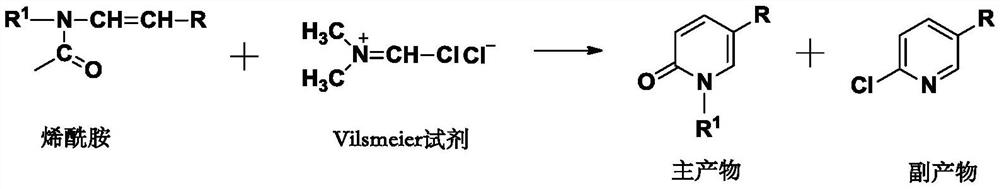

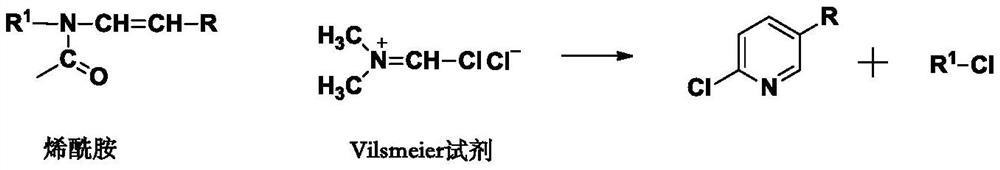

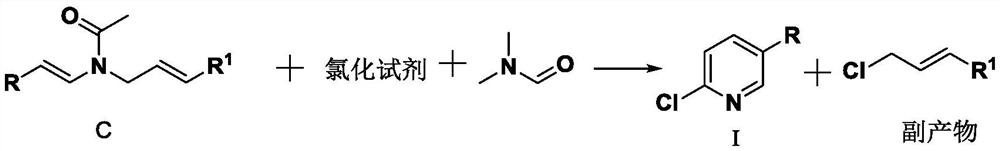

A kind of method for preparing 2-chloro-5-substituted pyridine

ActiveCN113402452BEasy to separateEasy to recycleHalogenated hydrocarbon preparationChemical synthesisMethylpyridinium

Owner:上海垚翀化工科技有限公司

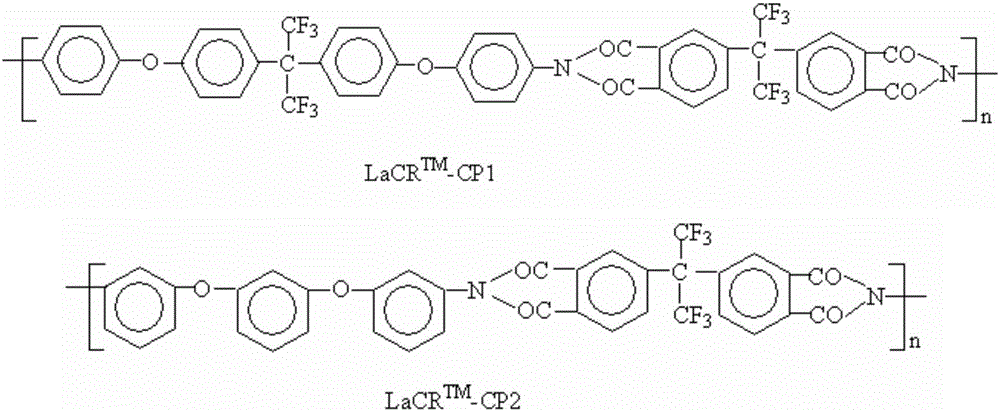

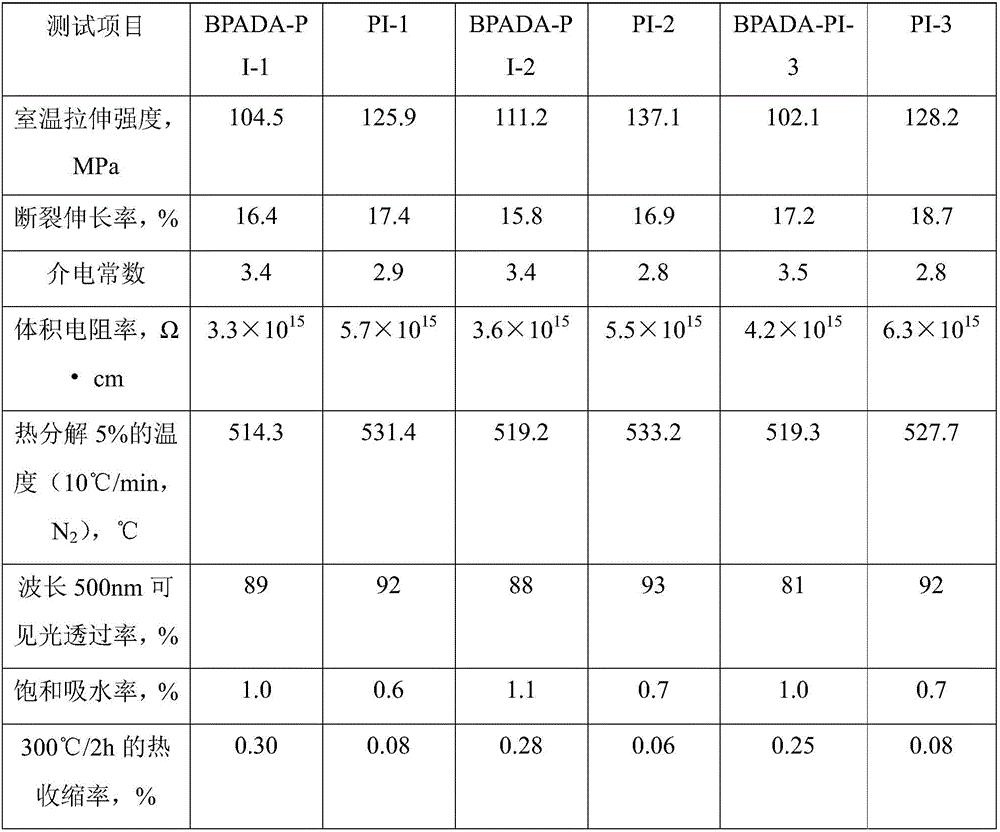

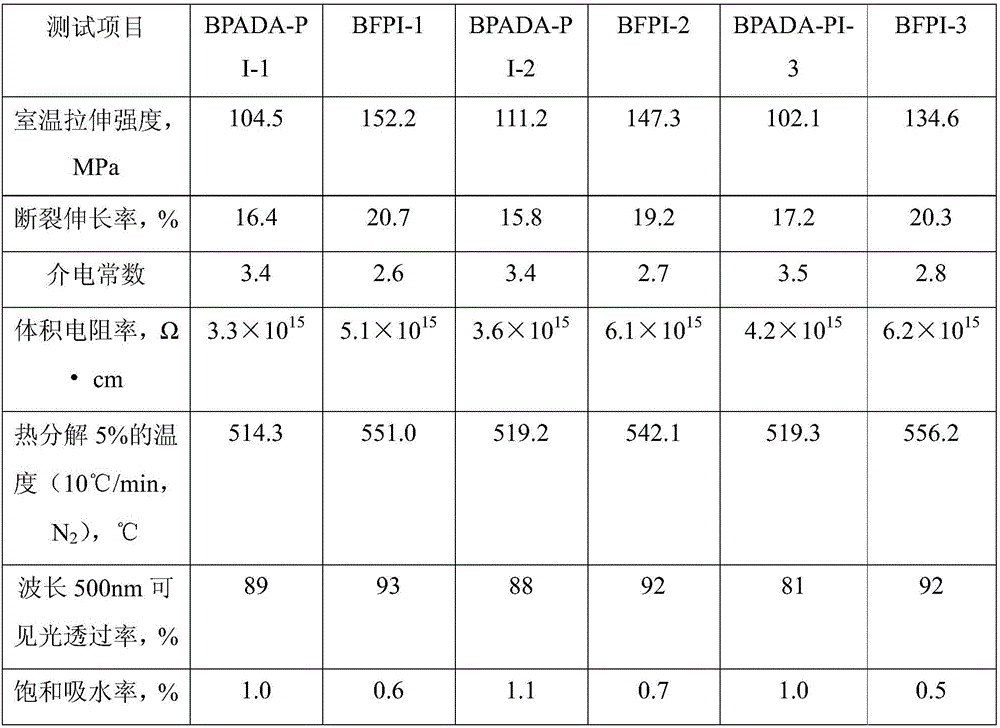

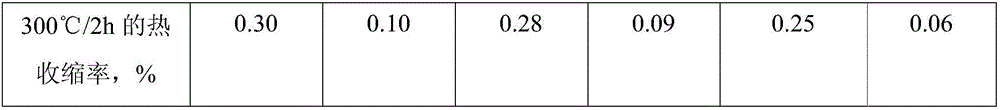

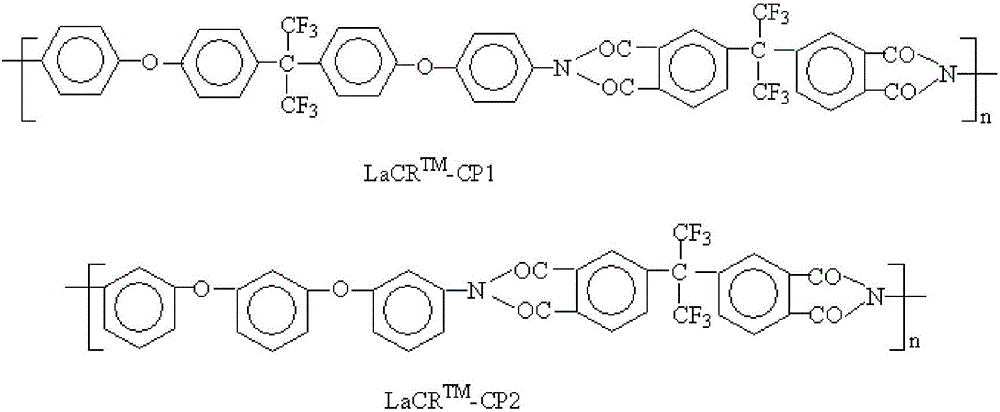

BPADA-type fluorine-containing branched polyimide resin film and preparation method thereof

The invention relates to a BPADA-type fluorine-containing branched polyimide resin film and a preparation method thereof. The mass ratio of BDAPFP and BPADA-type linear polyamide acids resins in the raw materials of the film is 1:100-800. The preparation method comprises the following steps: aromatic dicarboxylic primary amine and an aprotic organic solvent having strong polarity are mixed, a mixture is stirred under room temperature and then is cooled to the temperature of below 5 DEG C, BPADA is added and stirred, then is reacted for 1-6 hours at the temperature of 5-10 DEG C to obtain a BPADA-type polyamide acid resin solution; the resin solution and BDAPFP are mixed at room temperature, the mixture is stirred and is subjected to film forming, the material is heated, then is subjected to dehydration and thermal imidization, and the material is cooled and demoulded to obtain the product. The method has the advantages of mild condition, simple operation, low cost, and environment friendliness, is in favor of realizing industrial scale production, and can be used in the field of high technology such as flexible solar energy cells, space telescopes, large generator winding insulation, insulated wire lapping electrical insulating materials, and flexible copper-clad plates.

Owner:DONGHUA UNIV +1

BTDA-type 14BDAPB branched polyimide resin thin film and preparation method thereof

The invention relates to a BTDA-type 14BDAPB branched polyimide resin thin film and a preparation method thereof. In raw materials of the thin film, the mass ratio of 14BDAPB to the BTDA-type linear polyamide acid resin is 1:100-800. The preparation method includes the steps of: 1) mixing aromatic binary primary amine and a strong-polar non-protonic organic solvent, and stirring the mixture at room temperature, cooling the mixture to lower than 5 DEG C and adding the BTDA with stirring to carry out a reaction for 1-6 h at 5-10 DEG C to prepare a BTDA-type polyamide acid resin solution; and 2) mixing the resin solution and the 14BDAPB at room temperature, stirring the mixture to forming film, heating the mixture to perform dehydrating thermal imidization reaction, cooling the reaction product and releasing the film. The method has mild reaction conditions, is simple in operations, is low in cost and is environment-friendly, is beneficial to achievement of industrial large-scale production. The thin film can be applied in high-tech fields such as flexible solar cells, space telescope, major insulation of large motors, electrical insulating materials for lapping of electromagnetic wires, flexible copper-clad foil plates, etc.

Owner:DONGHUA UNIV +1

HQDA-type fluorine-containing branched polyimide resin film and preparation method thereof

The invention relates to a HQDA-type fluorine-containing branched polyimide resin film and a preparation method thereof. The mass ratio of BDAPFP-type linear polyamide acid resin to HQDA-type linear polyamide acid resin in the raw materials of the film is 1: (100 to 800). The preparation method comprises the following steps: mixing aromatic primary diamine with a strongly-polar aprotic organic solvent, stirring at room temperature, cooling to a temperature of below 5 DEG C, adding HQDA, stirring, and reacting for 1-6h at 5-10 DEG C to obtain a HQDA-type polyamide acid resin solution; and mixing the resin solution with BDAPFP at room temperature, stirring, carrying out film formation, heating, carrying out a dehydration thermal-imidization reaction, cooling, and carrying out film release to obtain the product. The method disclosed by the invention is moderate in reaction condition, simple to operate, low in cost, environment-friendly, beneficial to realizing large-scale industrial production, and capable of being applied to the high-technology fields of flexible solar cells, space telescopes, large motor main insulation, electromagnetic wire-lapping electrical insulation materials, flexible copper-clad plates and the like.

Owner:DONGHUA UNIV +1

BPDA-form 14BDAPB branched polyimide resin film and preparation method thereof

The invention relates to a BPDA-form 14BDAPB branched polyimide resin film and a preparation method thereof. The mass ratio of 14BDAPB to BPDA-form linear polyamide acid resin in the raw materials of the film is 1 to (100-800). The preparation method comprises the following steps: mixing aromatic binary primary amine with a strong-polarity aprotic organic solvent, stirring at the room temperature, cooling to a temperature below 5 DEG C, adding BPDA, stirring, and reacting at 5-10 DEG C for 1-6 hours, so as to obtain a BPDA-form polyamide acid resin solution; and mixing the resin solution with 14BDAPB at the room temperature, stirring to form a film, heating, and carrying out dehydration and thermal imidization, cooling, and removing a mold, so as to obtain the BPDA-form 14BDAPB branched polyimide resin film. The preparation method has the beneficial effects that the reaction conditions are mild, the operation is simple, and the cost is low; the BPDA-form 14BDAPB branched polyimide resin film is environmentally friendly, beneficial to the implementation of industrial large-scale production and can be applied to the high-tech fields of flexible solar cells, space telescopes, major insulation of big motors, electromagnetic wire lapped electrical insulating materials, copper-clad plates and the like.

Owner:DONGHUA UNIV +1

A rapid dehydration type air puffing equipment

The invention relates to puffing equipment, in particular to rapid dehydration type pneumatic-puffing equipment. A water catcher is arranged in a vacuum tank of the equipment, wherein a condenser pipe of the water catcher is paved in the vacuum tank in an S shape, and is connected with the water catcher through a snuffle valve below the vacuum tank; a drain valve is arranged at the lower end of the water catcher and is used for discharging condensate water in the water catcher. When the rapid dehydration type pneumatic-puffing equipment works, a lot of flashing hot steam generated by a lot of materials in the puffing tank due to rapid pressure relief penetrates through the water catcher, the hot steam is rapidly cooled and condensed into water due to fully heat exchange between the flashing hot steam and a refrigerating coil, is collected into a water collector through a pipeline, and then is discharged out of the equipment; a lot of hot steam is converted into liquid water and then is discharged by the water catcher in the vacuum tank in a vacuum state; the vacuum degree required for puffing and drying is kept; the workload of a vacuum pump assembly at the rear end is reduced; the drying rate of materials is greatly improved; the quality of a dry product is improved; and achievement of industrial large-scale production employing a pneumatic-puffing technology is facilitated.

Owner:JIANGSU ACAD OF AGRI SCI

BPDA type bisphenol A tetramine branched polyimide resin thin film and preparation method thereof

The invention relates to a BPDA type bisphenol A tetramine branched polyimide resin thin film and a preparation method thereof. The mass ratio of BDAPP to BPDA type linear polyamide acid resin in raw materials of the thin film is 1:(100-800). The preparation method includes the steps that aromatic binary primary amine and strong-polar non-proton solvent are mixed, stirred at the room temperature and cooled to the temperature below 5 DEG C, BPDA is added, stirring is conducted, the mixture reacts for 1 h to 6 h at the temperature ranging from 5 DEG C to 10 DEG C, and a BPDA type polyamide acid resin solution is obtained; the resin solution and the BDAPP are mixed at the room temperature and stirred, form a film and are heated, the dehydration fever imidization reaction is conducted, cooling is conducted, film stripping is conducted, and the BPDA type bisphenol A tetramine branched polyimide resin thin film is obtained. The method is gentle in reaction condition, easy to operate, low in cost, friendly to the environment, beneficial to implementation of industrialized scale production and capable of being applied to the high-tech fields of flexible solar cells, space telescopes, large generator main insulation, electromagnetic wire lapped electrical insulating materials, flexible copper-clad plates and the like.

Owner:DONGHUA UNIV +1

HQDA type 14BDAPB branched polyimide resin film and preparation method thereof

The invention relates to an HQDA type 14BDAPB branched polyimide resin film and a preparation method thereof. The mass ratio of 14BDAPB and HQDA type linear polyamide acid resin in raw materials of the film is 1 to 100-800. The preparation method comprises the steps that aromatic binary primary amine and a strong-polarity and non-proton organic solvent are mixed and stirred at room temperature, cooling is performed to reach 5 DEG C or below, HQDA is added, stirring is performed, reaction is performed at the temperature of 5-10 DEG C for 1-6 hours, and an HQDA type polyamide acid resin solution is obtained; the resin solution and the 14BDAPB are mixed at room temperature, stirring is performed, film formation, heating, dehydration and thermal imidization, cooling and mold release are performed to obtain the film. The method is mild in reaction condition, simple in operation, low in cost and environmentally friendly, facilitates industrial large-scale production and can be applied to the high-tech fields such as flexible solar cells, space telescopes, large motor major insulators, electromagnetic wire lapped electrical insulating materials and flexible copper-clad plates.

Owner:DONGHUA UNIV +1

A kind of anisotropic magnetic polymer composite film material and its preparation method

The invention discloses an anisotropic magnetic polymer composite film material and a preparation method thereof, belonging to the technical field of magnetic polymer composite materials. The composite film material includes FeCo magnetic nanoparticles and a polymer matrix. Preparation steps: 1) adding nano-FeCo cubic magnetic nanoparticles into the high molecular polymer, and stirring uniformly to obtain a mixture; 2) spin-coating the obtained mixture onto a glass sheet or a silicon sheet to form a thin film, and placing the obtained thin film on The "self-assembly" of magnetic particles is carried out in a magnetic field, and then solidified at a certain temperature to prepare an anisotropic magnetic polymer composite film. The invention has the advantages of simple process, easy control of film thickness, good directionality of the anisotropic self-assembled "nano rope", high production efficiency and good mechanical properties, and has potential application in high-tech fields such as flexible magnetic devices.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com