Preparation method of flexible flaky MoPCoP array electrolyzed water catalyst composite material

A composite material and water electrolysis technology, which is used in the preparation of flexible sheet-like MoPCoP array catalyst composite materials for water electrolysis, can solve the problems of HER catalytic activity and stability that cannot meet actual needs, and achieve excellent catalytic performance, large active area, The effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

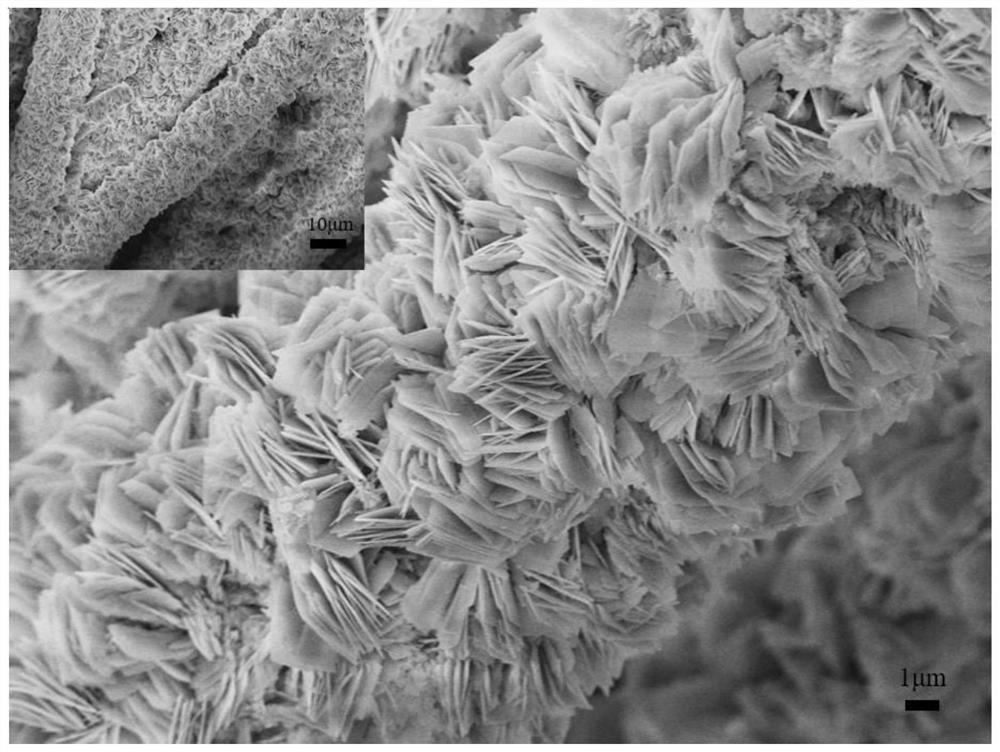

[0033] This embodiment provides a preparation method of a flexible sheet-like MoPCoP array catalyst composite material for electrolysis of water, comprising the following steps:

[0034] 1), prepare Co(NO according to 3mmol:2mmmol molar volume ratio 3 ) 2 ·6H 2 O, CH 4 N 2 O and 40ml deionized water, the Co(NO 3 ) 2 ·6H 2 O was added to deionized water and sonicated for 30 min and mixed well, then added CH 4 N 2 o Continue to sonicate for a certain period of time; put the mixed solution obtained by sonication together with the carbon cloth into the reaction kettle, keep at 100°C for 12h, and vacuum dry at 60°C for 12h after washing to obtain the carbon cloth-supported cobalt nanomaterial;

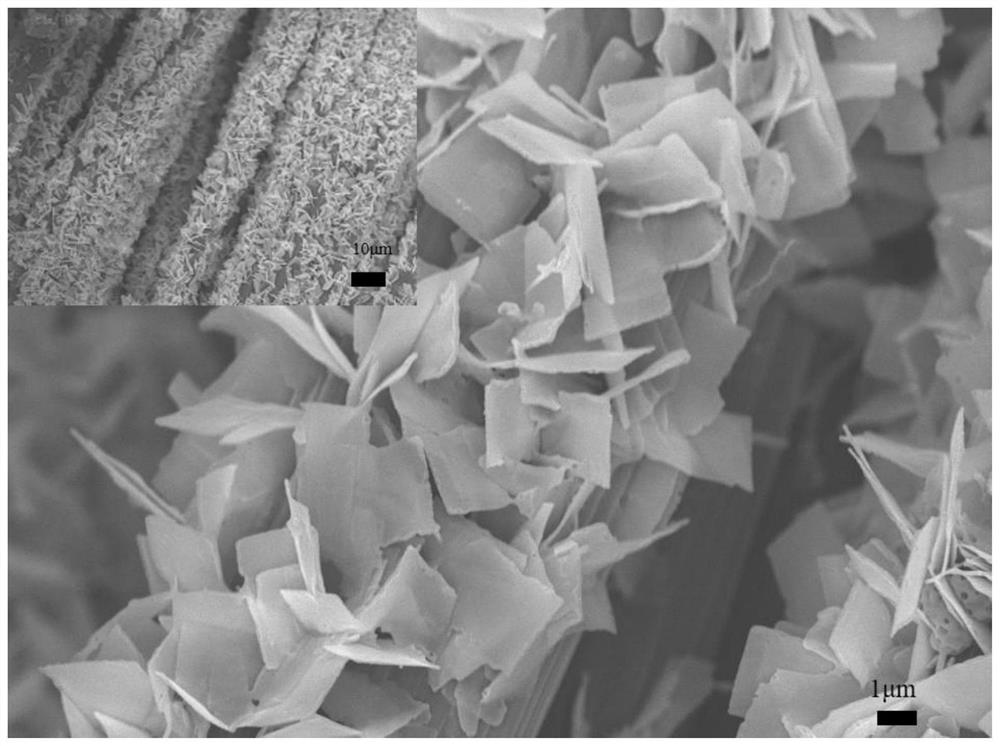

[0035] 2), the carbon cloth supported cobalt nanomaterial obtained in step 2) is placed in C 4 H 6 N 2 The solution was kept at room temperature for 24 hours, and after washing, the carbon cloth-supported nanomaterials were obtained by vacuum drying at 60 °C for 12 hours;

[003...

Embodiment 2

[0039] This embodiment provides a preparation method of a flexible sheet-like MoPCoP array catalyst composite material for electrolysis of water, comprising the following steps:

[0040] Step 1): Prepare Co(NO 3 ) 2 ·6H 2 O, CH 4 N 2 O and 40ml deionized water, the Co(NO 3 ) 2 ·6H 2 O was added to deionized water and sonicated for 30 min and mixed well, then added CH 4 N 2 o Continue to sonicate for a certain period of time; put the mixed solution obtained by sonication together with the carbon cloth into the reaction kettle, keep at 90°C for 12h, and vacuum dry at 60°C for 12h after washing to obtain a carbon cloth-supported cobalt nanomaterial;

[0041] Step 2): place the carbon cloth-supported cobalt nanomaterial obtained in step 1) in C 4 H 6 N 2 The solution was kept at room temperature for 24 hours, and after washing, the carbon cloth-supported nanomaterials were obtained by vacuum drying at 60 °C for 12 hours;

[0042] Step 3): Put H 4 MoNa 2 O 6 Put it i...

Embodiment 3

[0045] This embodiment provides a preparation method of a flexible sheet-like MoPCoP array catalyst composite material for electrolysis of water, comprising the following steps:

[0046] Step 1): Prepare Co(NO 3 ) 2 ·6H 2 O, CH 4 N 2 O and 40ml deionized water, the Co(NO 3 ) 2 ·6H 2 O was added to deionized water and sonicated for 30 min and mixed well, then added CH 4 N 2 o Continue to sonicate for a certain period of time; put the mixed solution obtained by sonication together with the carbon cloth into the reaction kettle, keep at 110°C for 12h, and vacuum dry at 60°C for 12h after washing to obtain the carbon cloth-supported cobalt nanomaterial;

[0047] Step 2): place the carbon cloth-supported cobalt nanomaterial obtained in step 1) in C 4 H 6 N 2 The solution was kept at room temperature for 24 hours, and after washing, the carbon cloth-supported nanomaterials were obtained by vacuum drying at 60 °C for 12 hours;

[0048] Step 3): Put H 4 MoNa 2 O 6 Put i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com