A kind of transition metal phosphide nanomaterial and its preparation method and application

A transition metal and nanomaterial technology, applied in the direction of phosphide, phosphorus compound, chemical instruments and methods, etc., can solve the problems of complex preparation method, poor catalyst stability, poor repeatability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

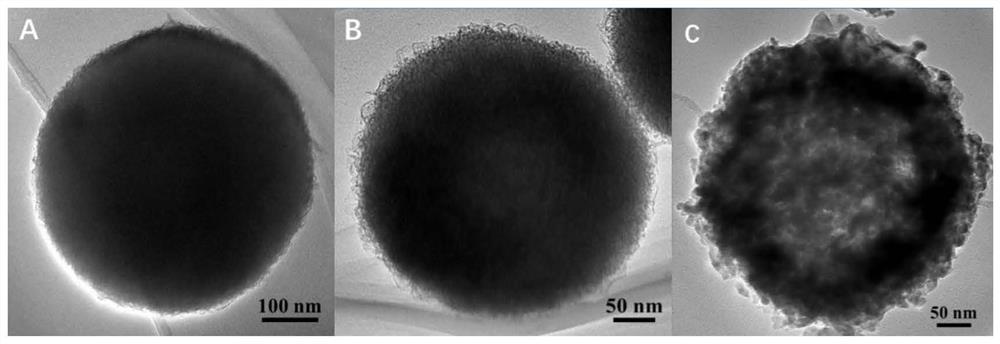

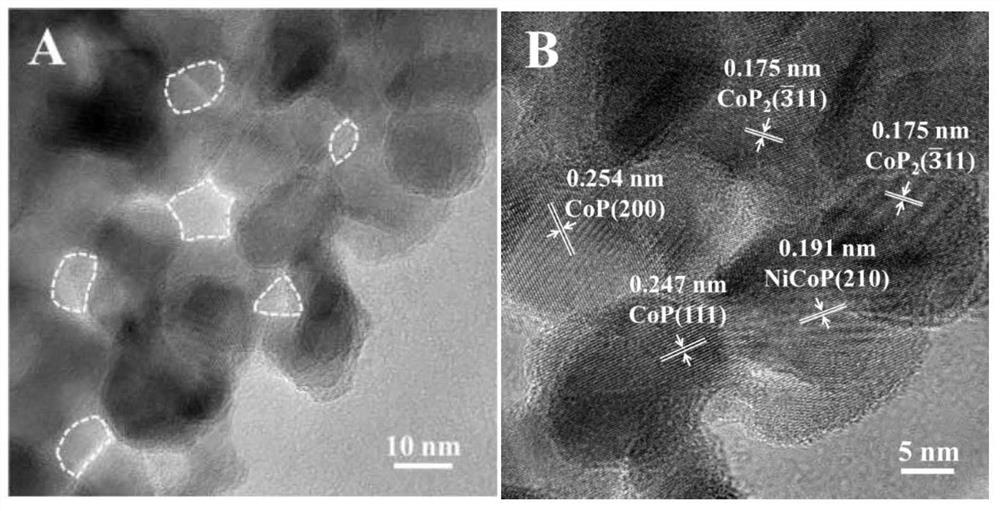

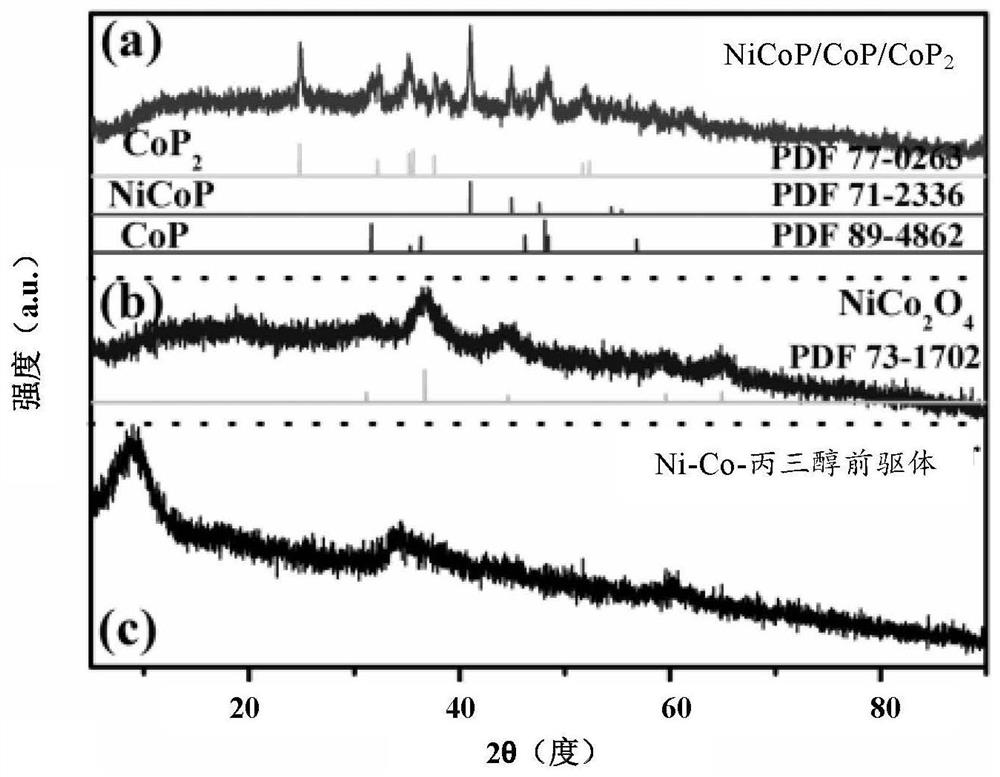

[0057] Example 1 NiCoP / CoP / CoP 2 Preparation of three-component transition metal phosphide nanomaterials

[0058] Preparation of Ni-Co-glycerol precursor

[0059] Dissolve nickel nitrate and cobalt nitrate in a polytetrafluoroethylene reactor filled with isopropanol, then add glycerol and water to form a mixed solution. In the mixed solution, the concentration of cobalt nitrate is 0.220mM, the concentration of nickel nitrate is 0.110mM, the concentration of isopropanol is 0.457M, the concentration of glycerol is 0.071M, and the concentration of water is 0.056mM. Then place the polytetrafluoroethylene reactor in a homogeneous reactor for heating, make the mixed solution react at a temperature of 190° C. for 12 hours at a stirring speed of 15 r / min, cool the obtained product at room temperature, and then The product was centrifuged, washed once with ethanol and water, and then dried at 105 °C to obtain the Ni-Co-glycerol precursor.

[0060] NiCo 2 o 4 preparation of

...

Embodiment 2

[0064] Example 2 NiCoP / CoP / CoP 2 Preparation of three-component transition metal phosphide nanomaterials

[0065] Preparation of Ni-Co-glycerol precursor

[0066] Dissolve nickel nitrate and cobalt nitrate in a polytetrafluoroethylene reactor filled with isopropanol, then add glycerol and water to form a mixed solution. In the mixed solution, the concentration of cobalt nitrate is 0.264mM, the concentration of nickel nitrate is 0.066mM, the concentration of isopropanol is 0.457M, the concentration of glycerol is 0.071M, and the concentration of water is 0.056mM. Then place the polytetrafluoroethylene reactor in a homogeneous reactor for heating, make the mixed solution react at a temperature of 190° C. for 12 hours at a stirring speed of 15 r / min, cool the obtained product at room temperature, and then The product was centrifuged, washed once with ethanol and water, and then dried at 105 °C to obtain the Ni-Co-glycerol precursor.

[0067] NiCo 2 o 4 preparation of

...

Embodiment 3

[0070] Example 3 NiCoP / CoP / CoP 2 Preparation of three-component transition metal phosphide nanomaterials

[0071] Preparation of Ni-Co-glycerol precursor

[0072] Dissolve nickel nitrate and cobalt nitrate in a polytetrafluoroethylene reactor filled with isopropanol, then add glycerol and water to form a mixed solution. In the mixed solution, the concentration of cobalt nitrate is 0.165mM, the concentration of nickel nitrate is 0.165mM, the concentration of isopropanol is 0.457M, the concentration of glycerol is 0.071M, and the concentration of water is 0.056mM. Then place the polytetrafluoroethylene reactor in a homogeneous reactor for heating, make the mixed solution react at a temperature of 190° C. for 12 hours at a stirring speed of 15 r / min, cool the obtained product at room temperature, and then The product was centrifuged, washed once with ethanol and water, and then dried at 105 °C to obtain the Ni-Co-glycerol precursor.

[0073] NiCo 2 o 4 preparation of

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com