Alkali-activated slag mortar mixed material and preparation method thereof

A technology for mixing materials and slag sand, which is applied in the field of alkali-excited slag mortar mixed materials and its preparation, can solve the problems of fast coagulation, large shrinkage and easy cracking, and achieves delaying coagulation time, improving distribution and orientation, good working performance and The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

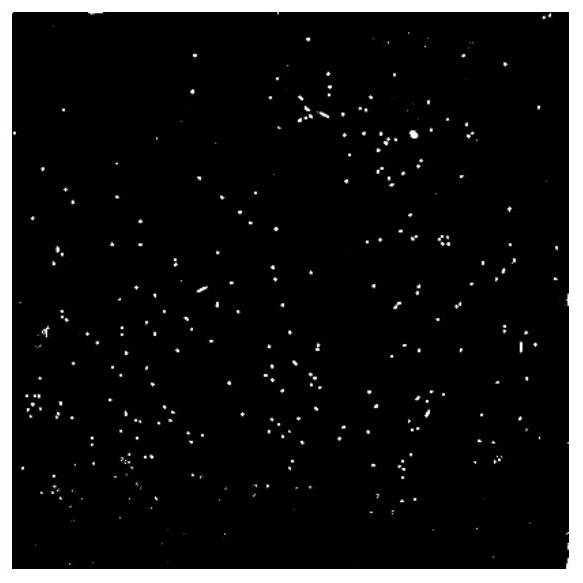

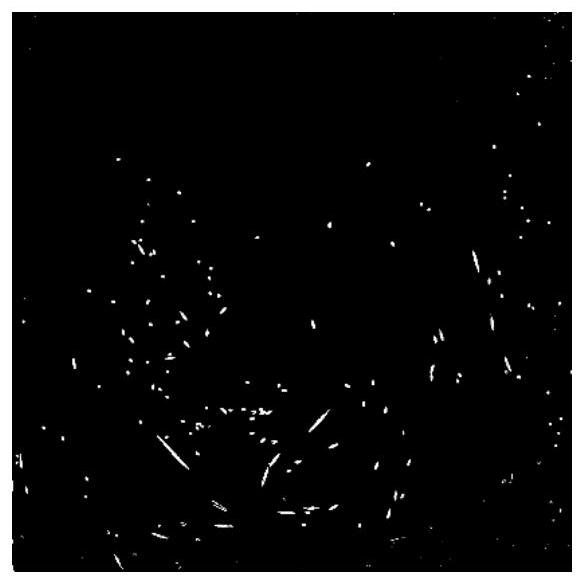

Method used

Image

Examples

preparation example Construction

[0030] Correspondingly, an embodiment of the present invention provides a method for preparing an alkali-activated slag mortar mixed material, which includes the following steps:

[0031]S1. Provide alkali-activated slag mortar, rigid fiber and tetrasodium hydroxyethylene diphosphonate;

[0032] S2. Mixing the alkali-activated slag mortar, the rigid fiber and tetrasodium hydroxyethylene diphosphonate to obtain the alkali-activated slag mortar mixed material.

[0033] The preparation method of the alkali-activated slag mortar mixed material provided by the embodiment of the present invention is simple to operate, does not require high equipment, and is conducive to realizing industrial scale production. The obtained alkali-activated slag mortar mixed material has good working performance and mechanical properties, which can meet the actual construction needs.

[0034] Specifically, in S1, the alkali-activated slag mortar can be conventional alkali-activated slag mortar in the ...

Embodiment 1

[0040] This embodiment provides a method for preparing an alkali-activated slag mortar mixed material, the steps are as follows:

[0041] (11) Accurately weigh 840 parts of slag, 1260 parts of sand, 24.33 parts of sodium hydroxide, 314.68 parts of water, 101.64 parts of water glass, 2.52 parts of tetrasodium hydroxyethylidene diphosphonate (accounting for 0.99‰ of the weight of alkali-activated slag mortar ) and 80 parts of steel fiber; wherein, the slag is S95 grade, which meets the index requirements of S95 grade slag powder in GB / T 18046; the sand is ISO standard sand produced in accordance with the requirements of GB / T17671-1999; sodium hydroxide is granular, The purity is 96%; the modulus of water glass is 3.34, and the mass percentage of water content is 62.3%; the length of steel fiber is 13mm, the diameter is 0.2mm, the tensile strength is ≥2000MPa, and the density is 7870kg / m 3 straight steel fibers;

[0042] (12) Alkali activator preparation: After mixing water glas...

Embodiment 2

[0045] This embodiment provides a method for preparing an alkali-activated slag mortar mixed material, the steps are as follows:

[0046] (21) Accurately weigh 840 parts of slag, 1260 parts of sand, 24.33 parts of sodium hydroxide, 314.68 parts of water, 101.64 parts of water glass, 5.04 parts of tetrasodium hydroxyethylidene diphosphonate (accounting for 1.98‰ of the weight of alkali-activated slag mortar ) and 80 parts of steel fiber; wherein, the slag is S95 grade, which meets the index requirements of S95 grade slag powder in GB / T 18046; the sand is ISO standard sand produced in accordance with the requirements of GB / T17671-1999; sodium hydroxide is granular, The purity is 96%; the modulus of water glass is 3.34, and the mass percentage of water content is 62.3%; the length of steel fiber is 13mm, the diameter is 0.2mm, the tensile strength is ≥2000MPa, and the density is 7870kg / m 3 straight steel fibers;

[0047] (22) Alkali activator preparation: After mixing water glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com