Placental lipopolysaccharide-polypeptide dual immunopotentiator and preparation method thereof

A technology for lipopolysaccharide and animal placenta, which is applied to the preparation methods of peptides, chemical instruments and methods, and food ingredients containing polysaccharide/gum, etc. Improve the use, sales and reporting of enhancers to achieve the effect of reducing the frequency of taking, improving the taste, and excellent water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

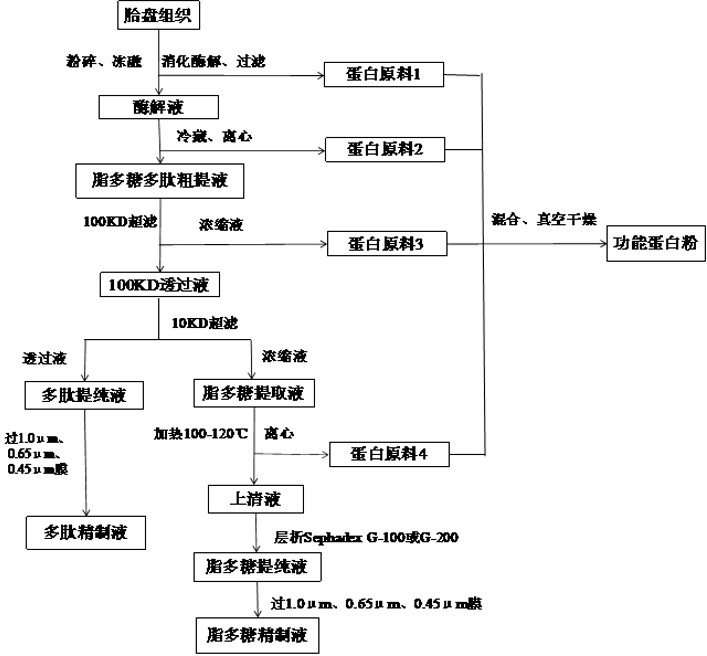

Image

Examples

Embodiment 1

[0039] A porcine placental lipopolysaccharide-polypeptide dual immunopotentiator, the specific preparation method comprising the following steps:

[0040] 1. Lipopolysaccharide and polypeptide co-production process

[0041] A. Raw material processing: 10 kg of fresh pig placenta that has passed the quarantine inspection is removed from the fetal membranes, umbilical cord, and blood clots, rinsed with pure water, crushed and ground with a meat grinder and colloid mill in turn, and then placed in a freezer below -20°C for 24 hours. , Take out the 37°C water bath to thaw, freeze and thaw three times like this, and then put it in the reaction kettle for digestion and enzymolysis.

[0042] B. Digestive enzymatic hydrolysis: Add physiological saline twice the weight of raw materials to the reaction kettle, add fresh pancreas juice with 30% weight of raw materials, adjust the pH value to 7.5 with saturated calcium hydroxide, heat to 50°C under intermittent stirring, and digest After...

Embodiment 2

[0063] A bovine placental lipopolysaccharide-polypeptide dual immunopotentiator, the specific preparation method comprising the following steps:

[0064] 1. Lipopolysaccharide and polypeptide co-production process

[0065] A. Raw material processing: 20 kg of fresh bovine placenta that has passed the quarantine is removed from the placenta, umbilical cord, blood clot and other appendages, rinsed with pure water, crushed and ground with a meat grinder and colloid mill in turn, and placed in a cold storage below -20°C Quick-freeze for 48 hours, take out the 37°C water bath to thaw, and freeze-thaw 5 times in this way, and then put it in the reaction kettle for digestion and enzymolysis.

[0066] B. Digestive enzymatic hydrolysis: Add physiological saline 3 times the weight of raw materials to the reaction kettle, add fresh pancreas juice with 50% weight of raw materials, adjust the pH value to 8.5 with saturated calcium hydroxide, heat to 55°C under intermittent stirring, and di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com