Aeolotropic magnetic high polymer composite film material and preparation method thereof

A technology of polymer materials and composite films, which is applied in the field of nanomaterial composite film preparation, can solve the problems of affecting the magnetic anisotropy performance of films, poor orientation, and limited application range, etc., and achieve easy control of film thickness, good orientation, and expansion The effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

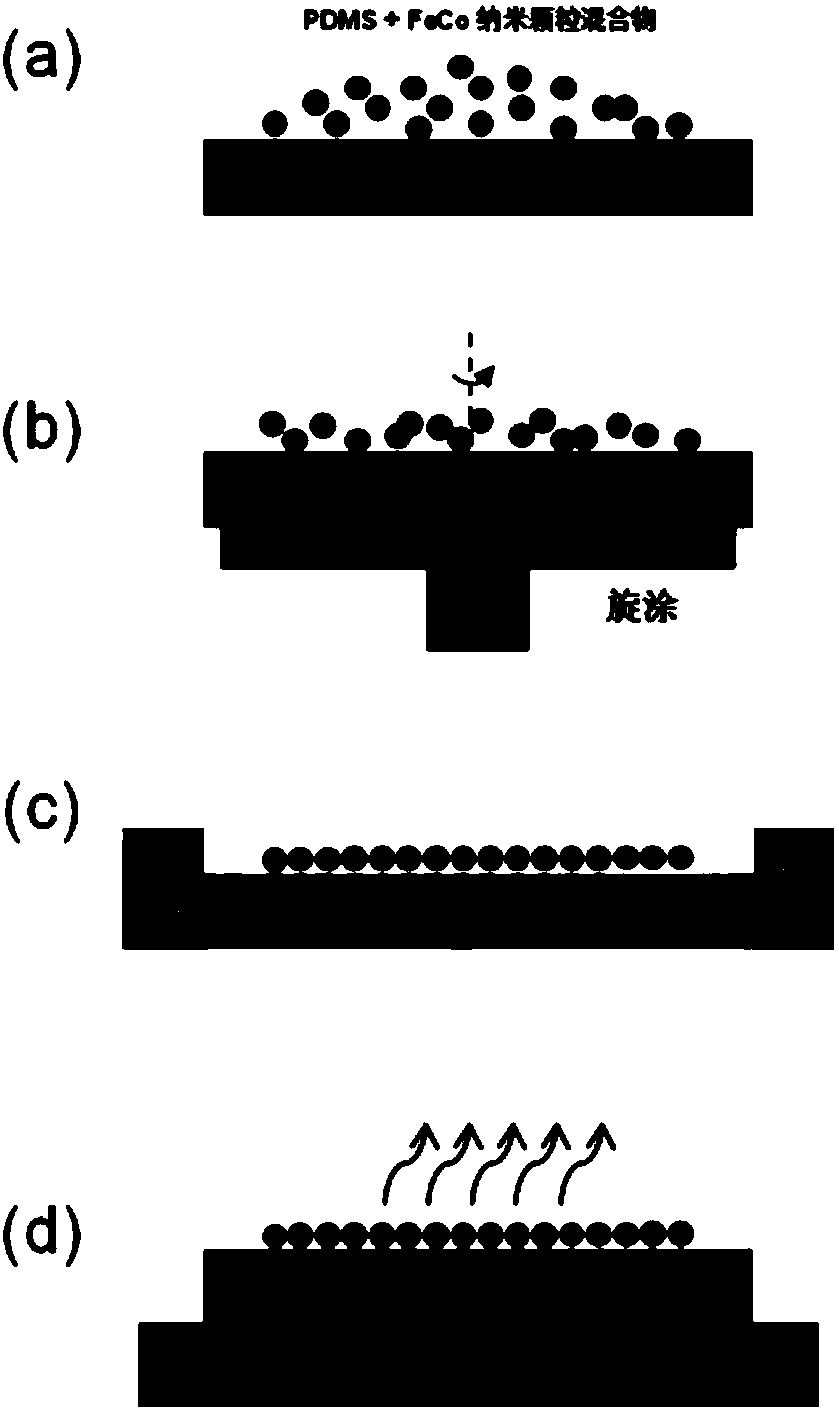

[0031] The present invention is an anisotropic magnetic polymer composite thin film material and a preparation method thereof, and its preparation process is as follows figure 1 , including the following steps:

[0032] 1. Mix Part A and Part B of the commercial polymer polydimethylsiloxane (PDMS) Hasuncast RTVS603 at a mass ratio of 1:1, and stir evenly to obtain a mixture;

[0033] 2. Grind the synthesized vacuum-dried FeCo cubic magnetic nanoparticles by hand for 20-40 minutes, add them into the mixture according to the mass fraction of 0.05%-10%, and ultrasonicate for 2-3 hours after stirring, so that the nanoparticles and polymers Mix well to form a homogeneous FeCo-PDMS mixture;

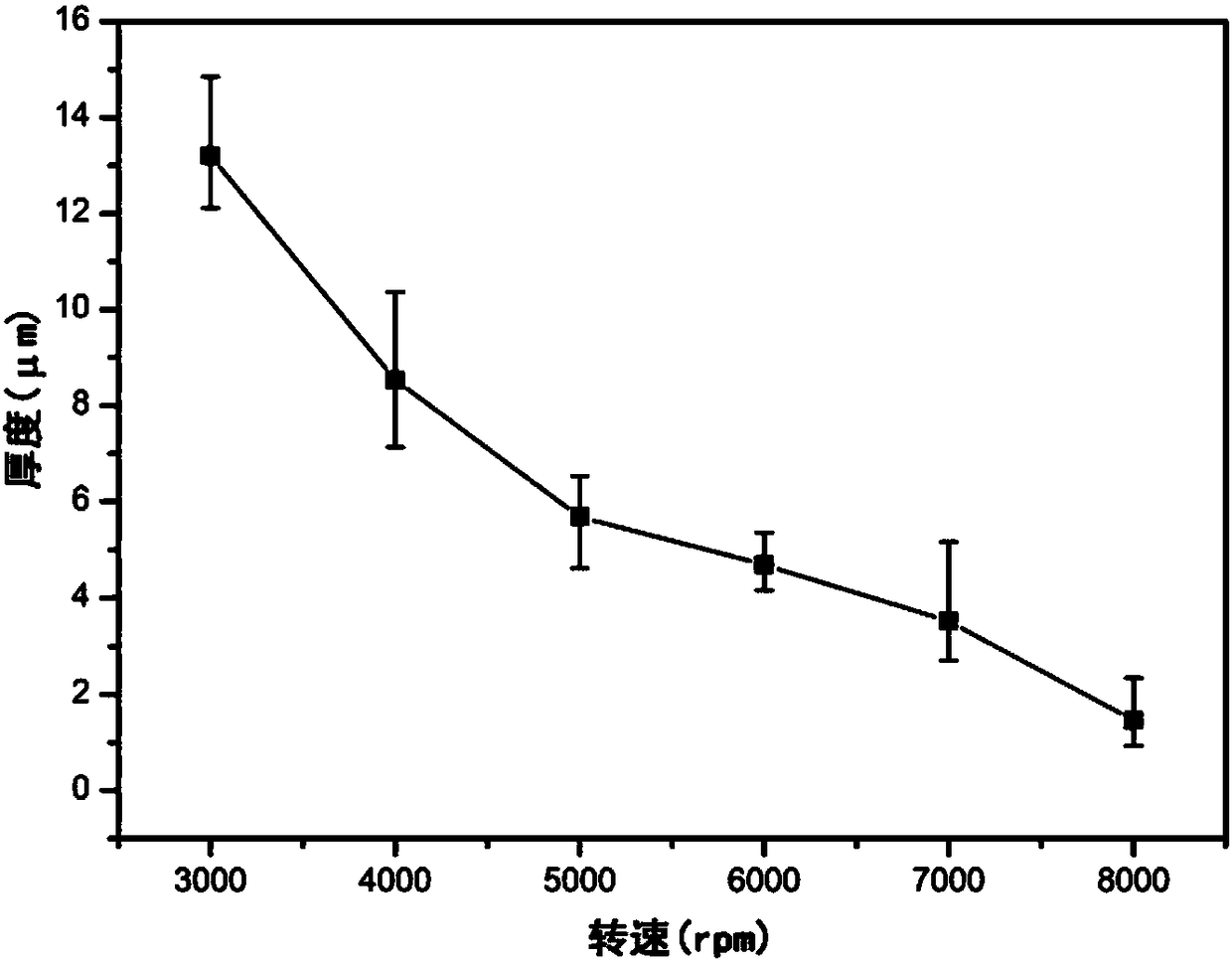

[0034] 3. Place the fully mixed FeCo-PDMS mixture in a vacuum environment and let it stand for 30 minutes to exhaust the air bubbles; use a cleaned glass or silicon wafer as the substrate, and use a spin coating device to remove the air bubbles from the FeCo-PDMS. The mixture is spin-coated i...

Embodiment 1

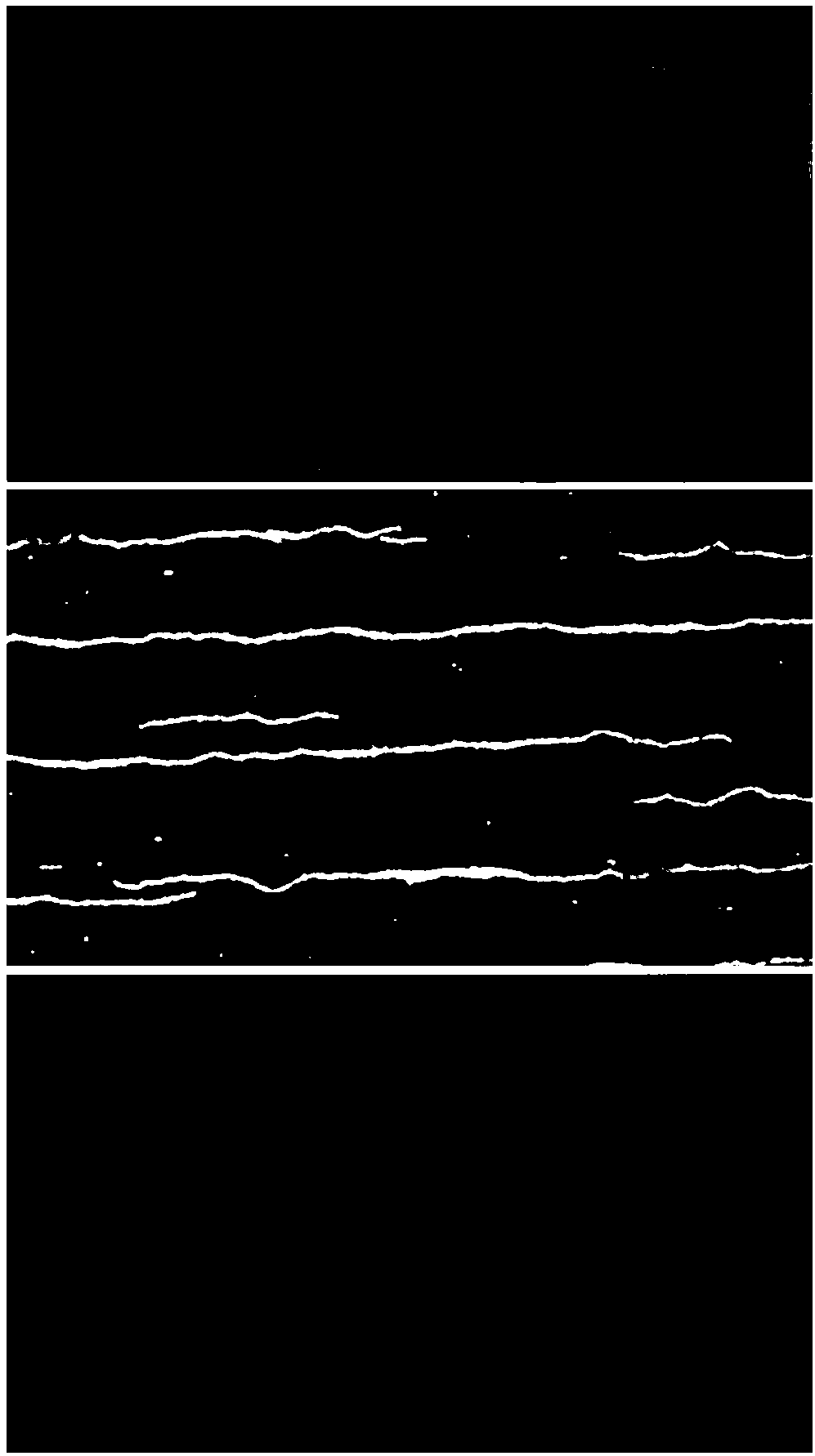

[0041] In this embodiment, an anisotropic magnetic polymer composite thin film material is prepared, wherein the applied magnetic field strength is 140 mT, and the mass fraction of FeCo cubic nanoparticles (170 nm) is 1%. Concrete preparation process is as follows:

[0042] 1. Weigh Part A and Part B of commercial polymer polydimethylsiloxane (PDMS) Hasuncast RTVS603, mix according to the mass ratio of 1:1, and stir to obtain a polymer;

[0043] 2. Grind the synthesized vacuum-dried FeCo magnetic nanoparticles by hand for 30 minutes, and evenly add them to the polymer according to the mass fraction of 1%. After stirring evenly, ultrasonic 3 hours, so that the nanoparticles and polymers are fully mixed to form a uniform FeCo-PDMS mixture;

[0044]3. Put the fully mixed FeCo-PDMS mixture in a vacuum box and let it stand for 30 minutes to exhaust the air bubbles; use a cleaned glass or silicon wafer as the substrate, and use a spin coating device to remove the air bubbles from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com