Supportive element capable of supporting ball screws with different shaft end size

A technology of ball screw and support unit, which is applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc. It can solve the problems of impact, centering accuracy cannot be guaranteed, and shaft sleeve installation is not accurate, etc., to achieve convenient disassembly, The effect of avoiding loss of precision and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

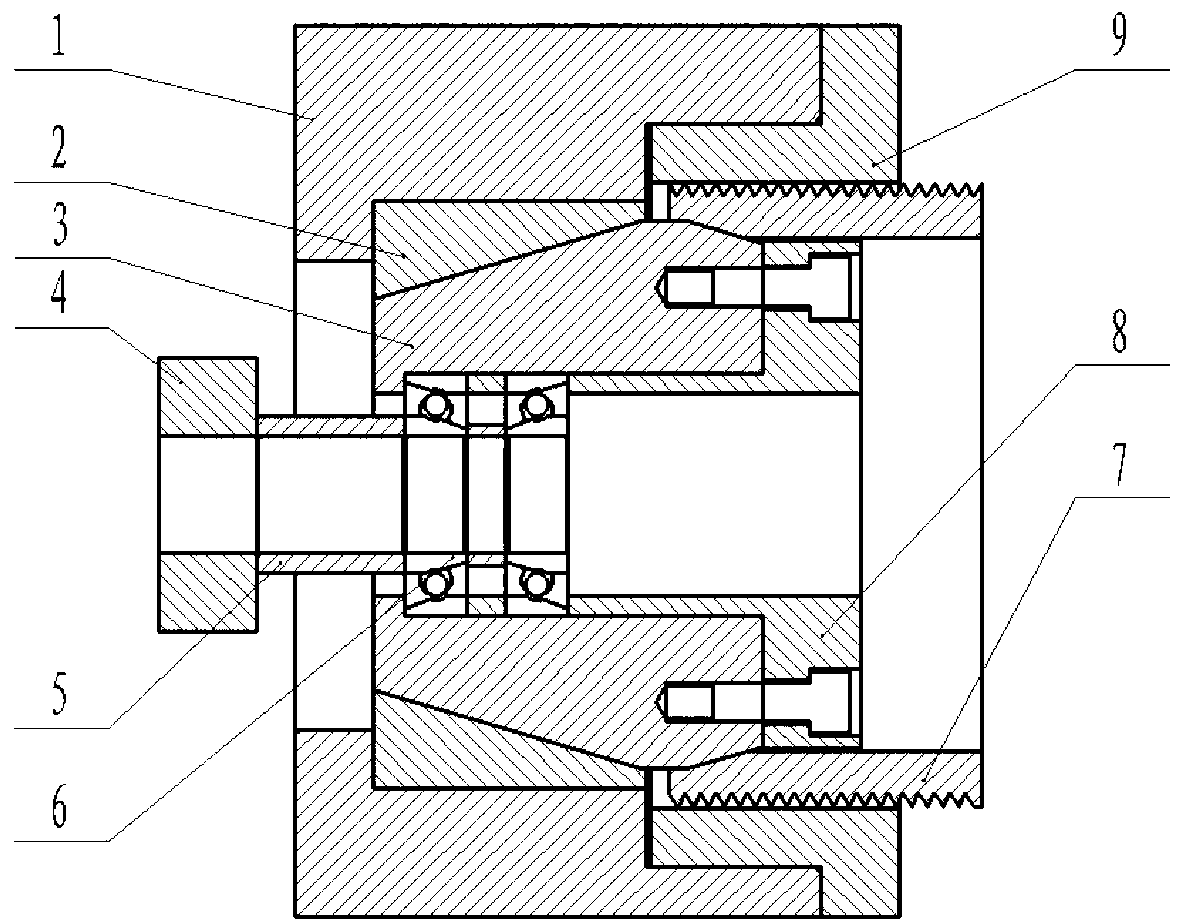

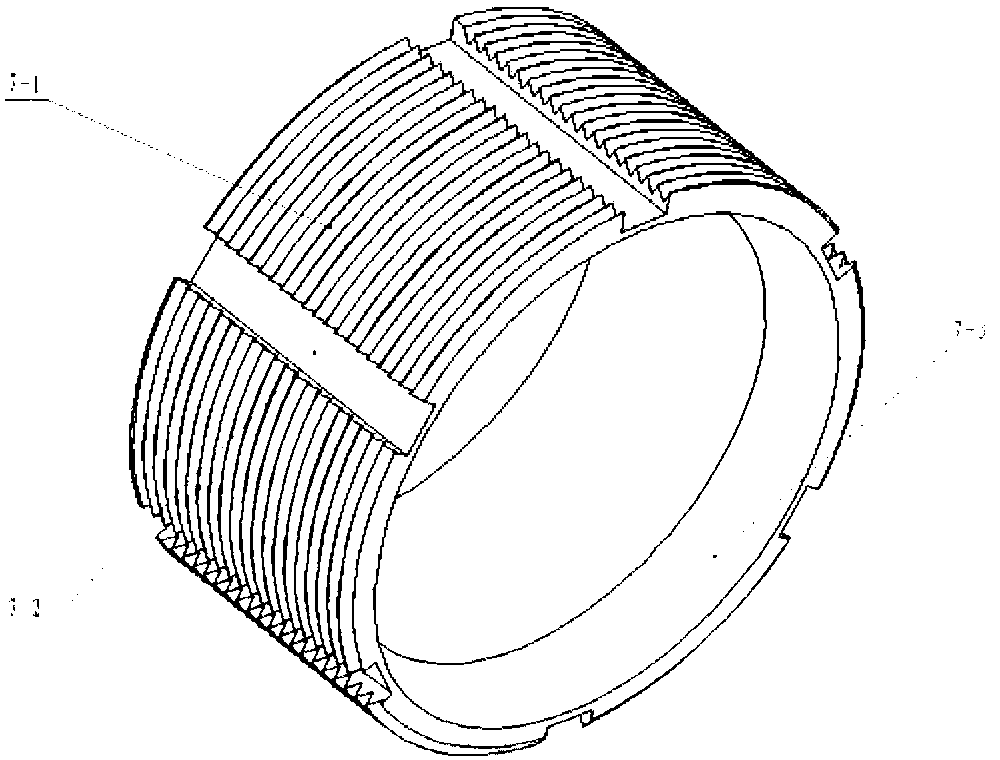

[0011] A support unit capable of supporting ball screws with different shaft end sizes, including a support seat 1, an inner taper sleeve 2, a spring taper sleeve 3, a lock nut 4, a spacer sleeve 5, a bearing 6, a compression nut 7, and an elastic retainer Ring 8 and threaded sleeve 9;

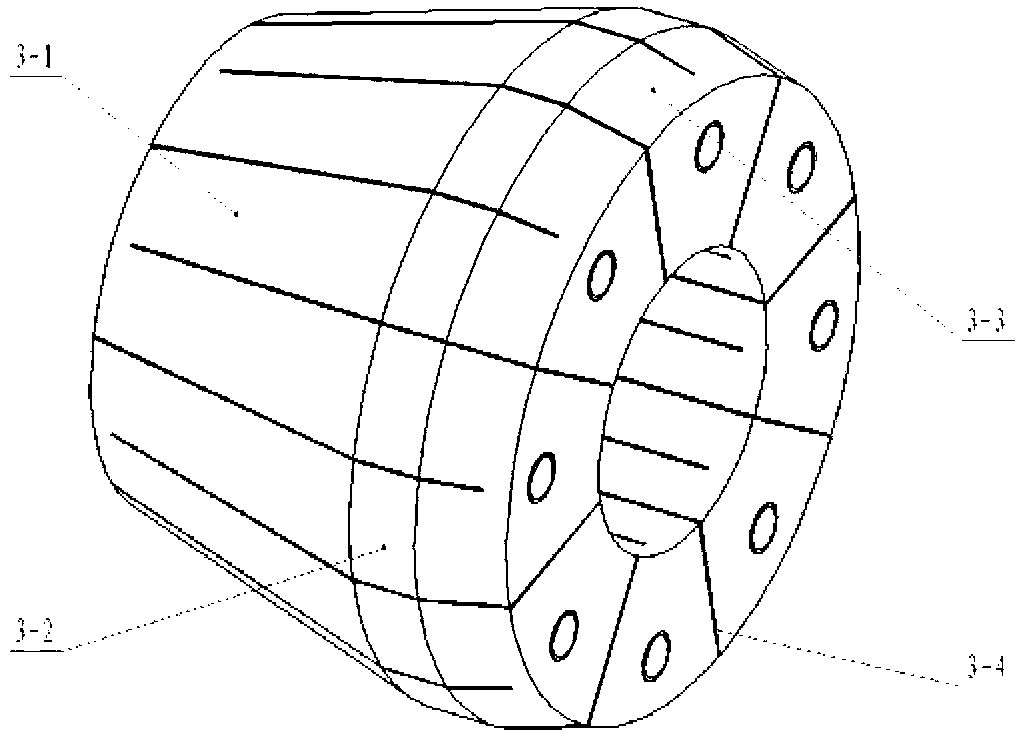

[0012] The inner taper sleeve 2 is set in the support seat 1, and the positioning surface of the support seat 1 is positioned against the inner taper sleeve 2. The support seat 1 is also provided with a threaded sleeve 9, and the threaded sleeve 9 is fixed on the support seat 1 by screws. The inside of the taper sleeve 2 is provided with a spring taper sleeve 3, which can be accurately centered through the cooperation of the taper surface. The spring taper sleeve 3 is equipped with a bearing 6, and the elastic retaining ring 8 is fastened to the spring taper sleeve 3 by screws. The end face of the circlip 8 axially positions the bearing 6, and the conical surface of the compression nut [7] coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com