Edge covering process of flexible fabrics

A cloth and flexible technology, applied in the field of garment processing, can solve problems such as uneven width of hemming, hemming folds, and bending of hemming lines, so as to ensure quality, prevent deformation and bending, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the utility model content, characteristics and effects of the invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

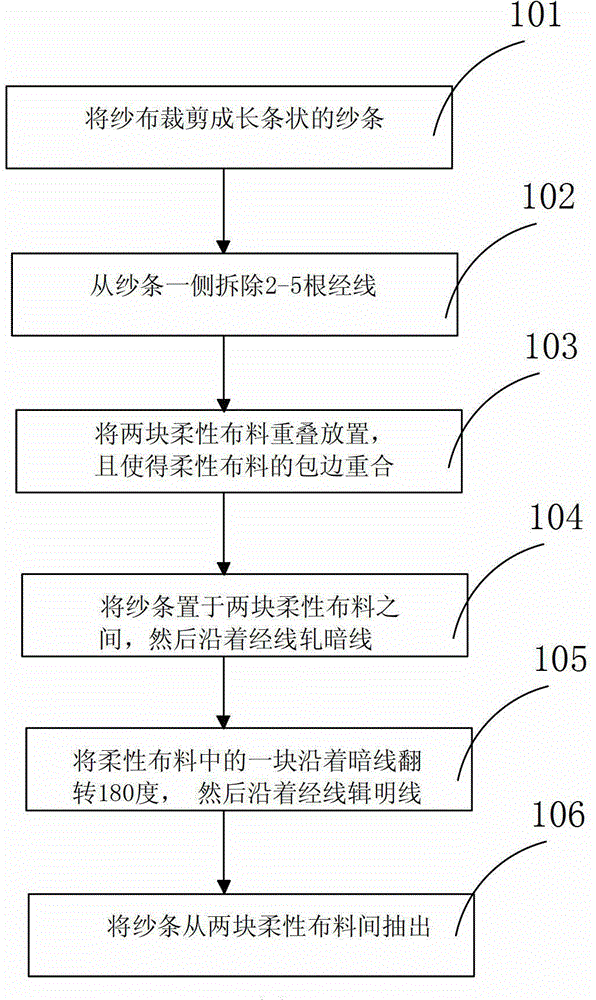

[0020] See figure 1 , figure 2 , a kind of hemming process of flexible cloth, comprises the following steps:

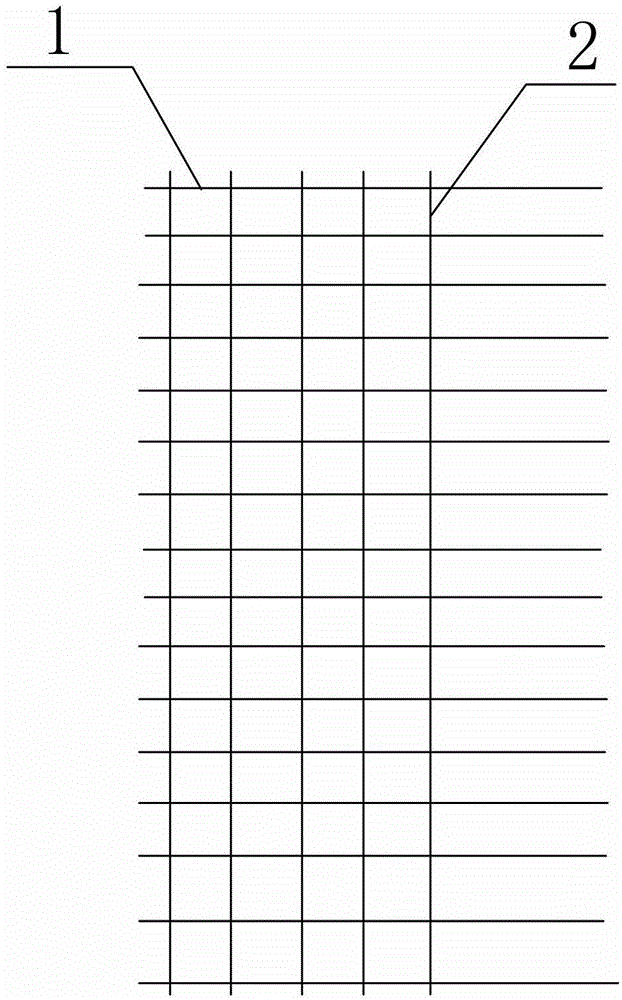

[0021] Step 101, cutting the gauze into elongated sliver; wherein, the sliver is formed by weaving the weft 1 and the warp 2 orthogonally; and: the width of the sliver is preferably 1cm-4cm; The width of adjacent wefts is not less than 2mm-5mm;

[0022] Step 102, remove 2-5 warp threads from one side of the sliver; the number of threads to be removed is determined by the width of the hemming and the distance between adjacent warp threads 2, that is, the width of the hemming is equivalent to the width of the removed warp thread 2; The root number is the width of the wrapping divided by the distance between adjacent warps 2,

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com