Compression pin head forming progressive die

A technology of progressive dies and compression pins, which is applied in the direction of forming tools, metal processing equipment, stripping devices, etc., can solve the problems of increased error in the completion of division of labor for multiple sets of equipment, unfavorable modernization operations, poor continuous ability, etc., and achieve effective It is conducive to sustainable development, saves the trouble of changing molds and debugging, and reduces the effect of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

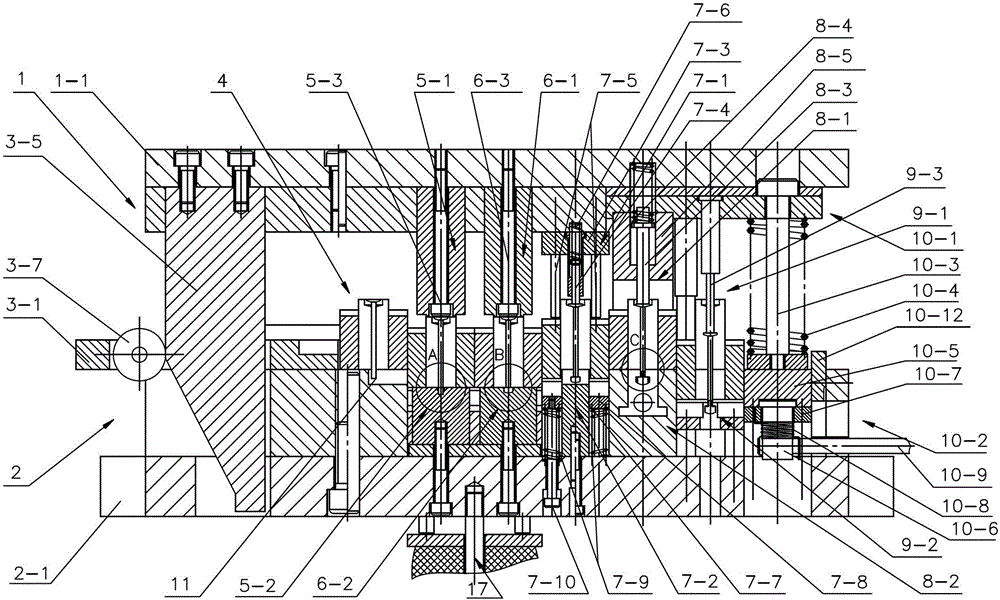

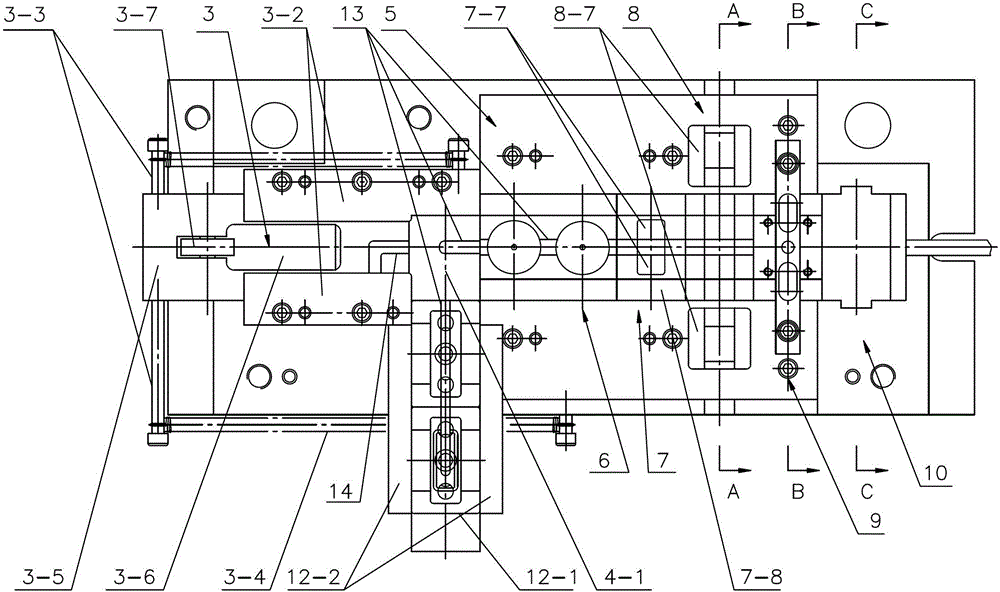

[0052] see figure 1 figure 2 , the compression pin head forming progressive die, including:

[0053] Upper mold 1, upper mold 1 includes upper mold base 1-1;

[0054] Lower mold 2, lower mold 2 includes lower mold base 2-1;

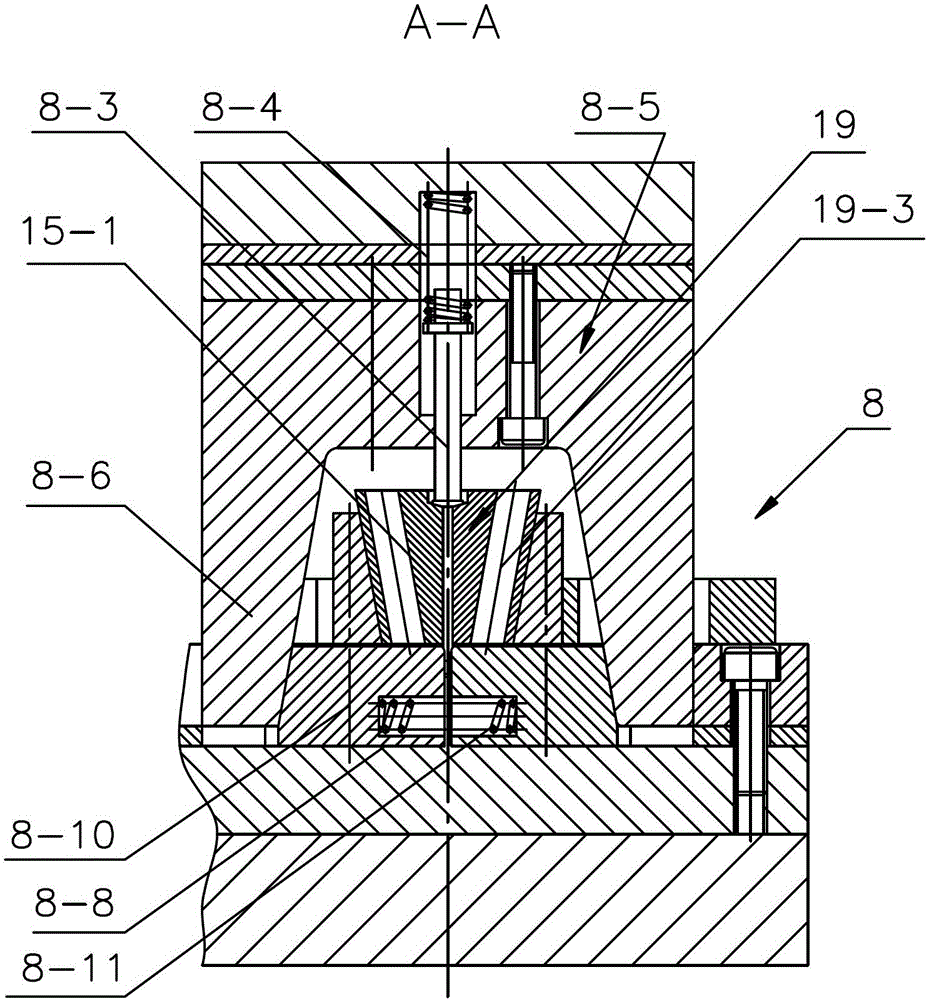

[0055] Core mold sleeve, refer to Figures 14 to 17 , consists of a core set 15 and a mold sleeve 16. The core set 15 is a double split type, and is composed of two symmetrically arranged cores 15-1. The counterbore 15-2 of the pin 11, a mold cover 16 for clamping the core set 15 is set on the outer wall of the core set 15; The notch 16-2 in the mold cover 16 has a notch 16-1 in the middle of the mold cover 16. The cross section of the notch 16-1 is an isosceles trapezoid, and the core group 15 is an isosceles trapezoid shape. 16-1 is the surface connection.

[0056] Two edges of the big end surface of the mold core set 15 are symmetrically provided with jacks 15-3, and the inclination angle and direction of the jack 15-3 are the same as the inclin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap