Upper sliding block suppressing force display mechanism of powder make-up machine

A technology of powder molding machine and display mechanism, which is applied in the field of powder metallurgy, can solve the problems of loss, inability to adjust the size of the pressing force, and easily damaged mechanisms, and achieve the effects of preventing jamming, facilitating timely adjustment, and facilitating reverse driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

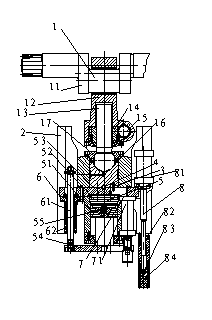

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail in conjunction with whole mechanism:

[0015] 1. Upper slider ball head screw adjustment mechanism 1:

[0016] This mechanism: (1) is used to adjust the pressurization amount of the upper die punch during pressing, that is, adjust the upper slider mechanism including the upper slider 2; (2) drive the upper slider connecting rod 12 by the transmission crankshaft 11, Complete the pressing and pressing process of the upper slider 2; (3) The closing height of the machine can be adjusted by adjusting the mechanism when the machine is assembled. Head anti-rotation ring 16 stops rotation, makes it can only move up and down under the drive of worm gear 14, thereby drives upper slider mechanism to move up and down by ball head changing plate 17, finishes adjustment process.

[0017] 2. Hydraulic cushion pressure display mechanism 5:

[0018] This mechanism monitors the working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com