Pipe rotation limiting device

A technology of rotational restraint and pipeline, applied in the direction of pipeline bracket, pipe/pipe joint/pipe fitting, mechanical equipment, etc., which can solve problems such as installation space limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

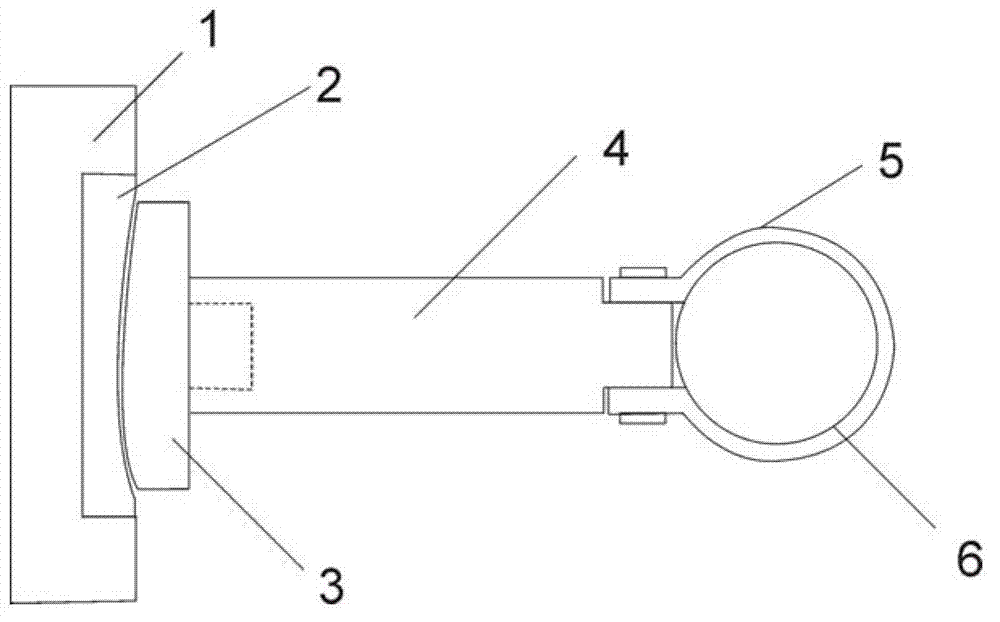

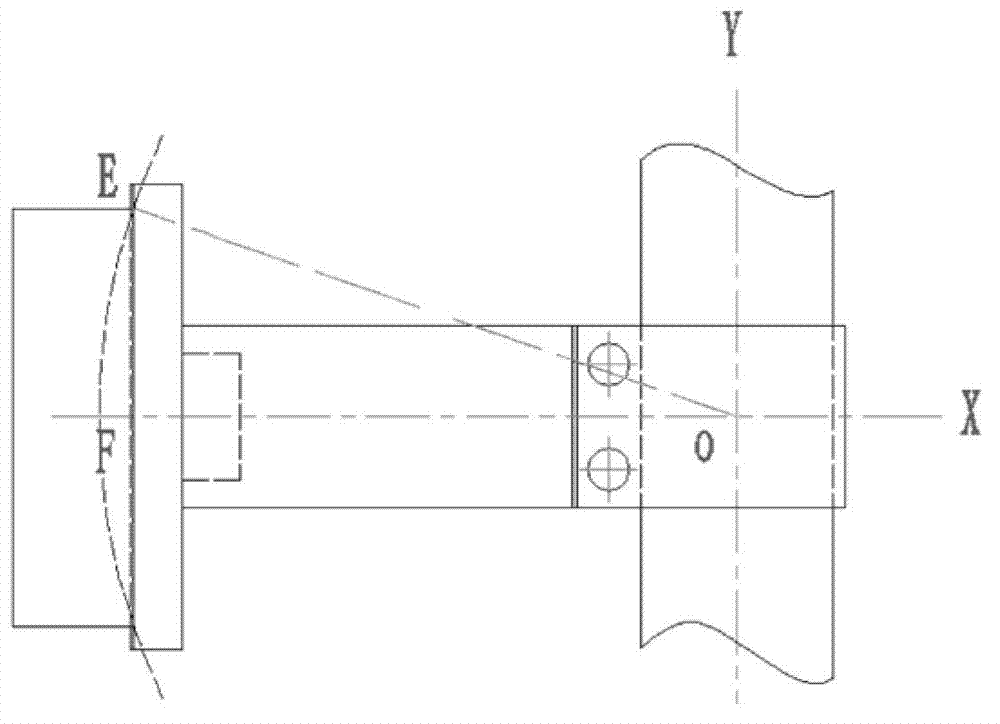

[0028] Pipe rotation restraint device, the device is mainly composed of baffle plate 1, concave arc insert 2, convex arc insert 3 and T-beam 4, wherein the concave arc The insert is clamped into the T-beam 4 by the expansion joint process, one end of the T-beam 4 is fastened to the pipe 6 through the clamp 5, and the convex arc insert 3 at the other end is put into the arc groove of the concave arc insert 2, and the convex The convex arc surface of the arc insert 3 and the concave arc surface of the concave arc insert 2 are both concentric cylindrical surfaces with the center of the pipe as the center, and the convex and concave arc surfaces coincide. The baffle 1 is fastened to the ground or the wall by using bolts or welding. The materials of the baffle plate 1, the concave arc insert 2, the convex arc insert 3, the T-beam 4 and the clip 5 are all stainless steel. Both the convex arc insert 3 and the concave arc insert 2 are quenched and hardened to increase wear resistance...

Embodiment 2

[0034] The difference from Embodiment 1 is that two sets of pipeline restraint devices are used and installed in two directions orthogonal to each other, so that the function of restraining two torques can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com