Butt welding galvanized elbow

A technology of butt welding and elbows, which is applied in the direction of elbows, pipes/pipe joints/fittings, non-detachable pipe connections, etc. It can solve the problems of large waste of raw materials and difficult sealing of joints

Inactive Publication Date: 2013-06-05

江苏海德节能科技有限公司

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

They are all rolled up, which not only wastes a lot of raw materials (galvanized steel sheets), but also makes it difficult to seal the joints due to the existence of the rolls.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

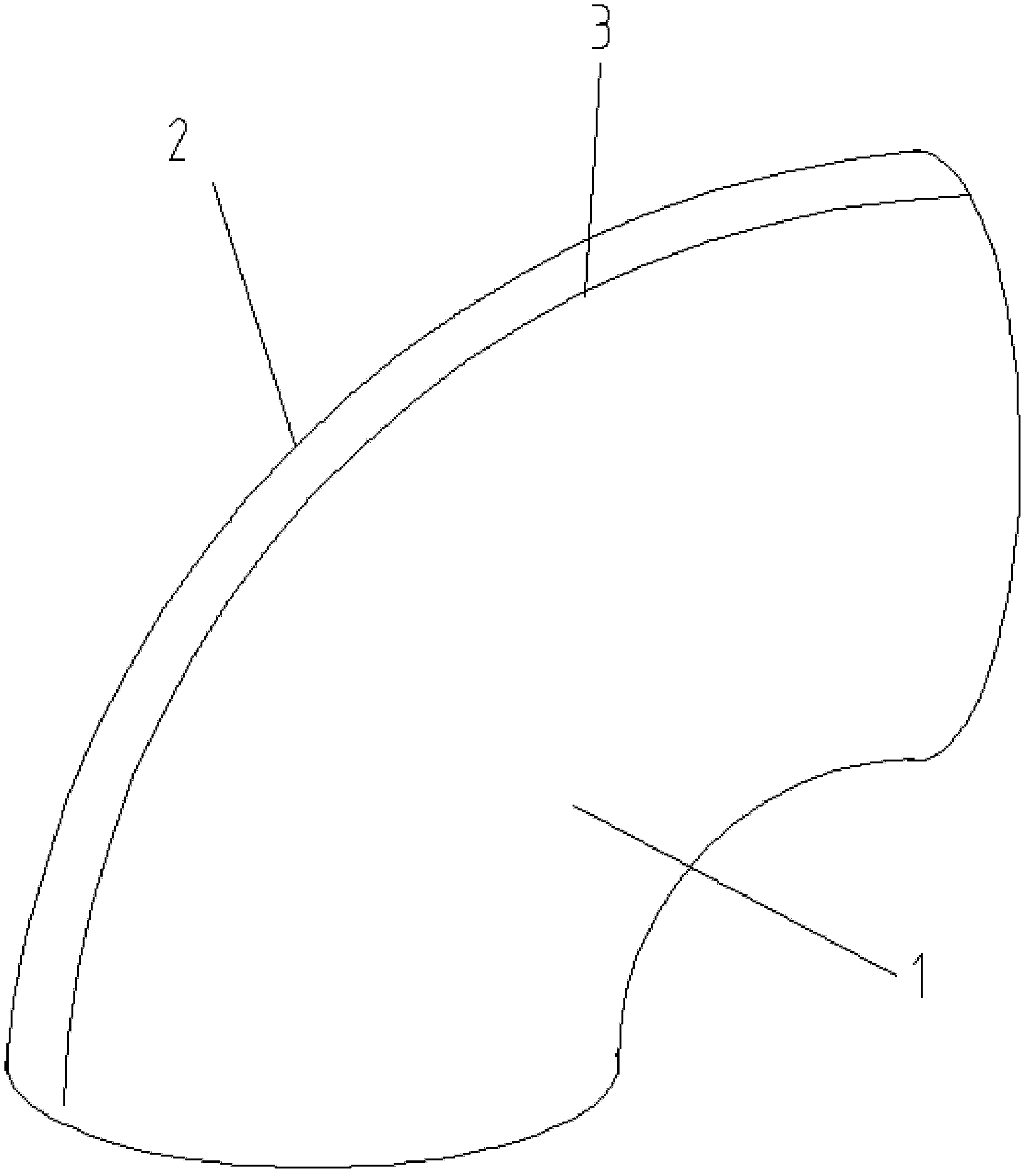

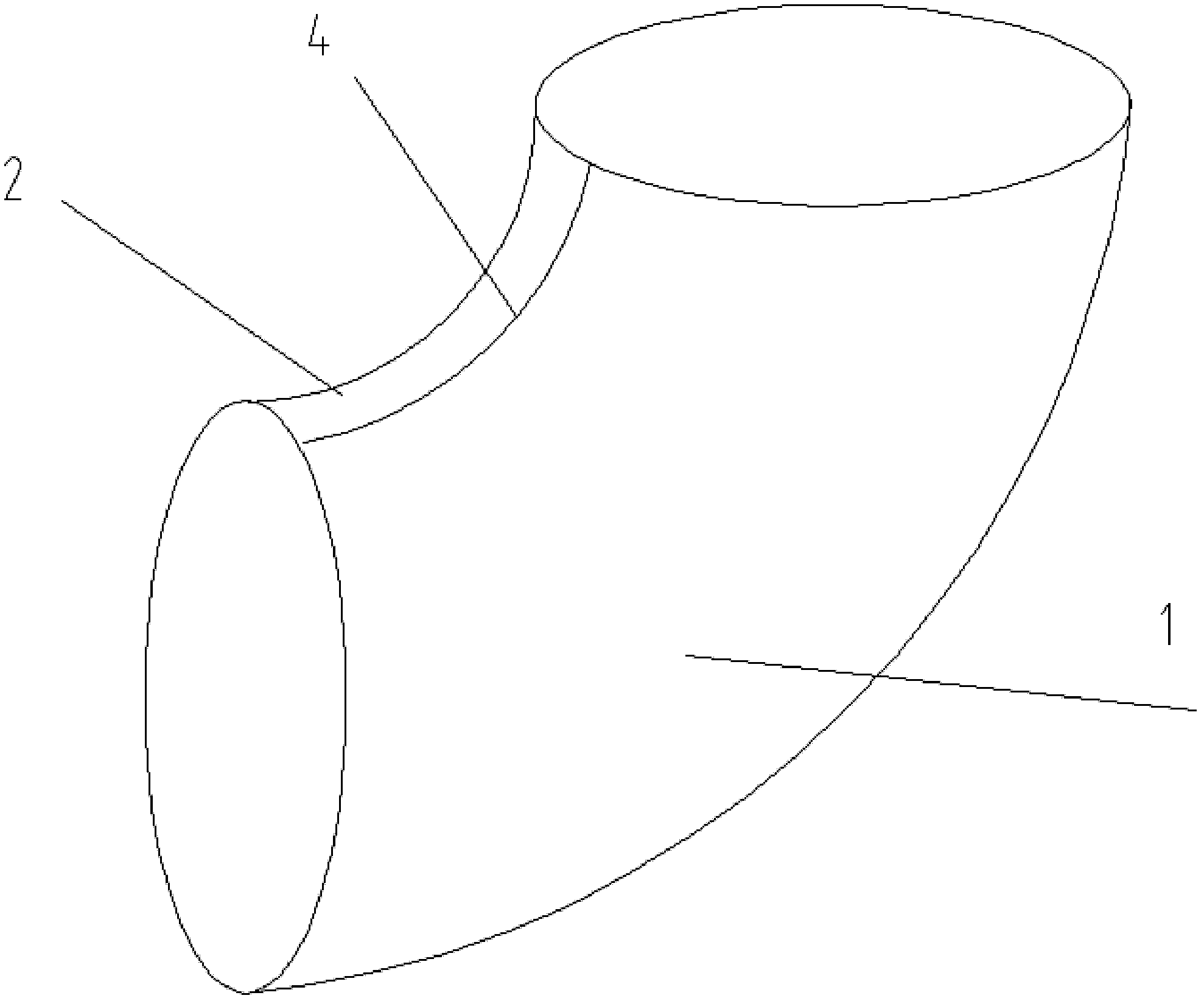

A butt welding galvanized elbow is characterized by comprising a left elbow half right-angle arc (1) and a right elbow half right-angle arc (2), the left elbow half right-angle arc (1) and the right elbow half right-angle arc (2) are welded into the integrated galvanized elbow in a butting mode. The butt welding galvanized elbow has the advantages that inside and outside welding joint arc welding is performed for the two half right-angle arc work pieces in a punch forming mode in advance in the butting mode to complete welding, and the welding process changes the prior edge landing and withdrawing process.

Description

technical field [0001] The invention relates to a butt welding galvanized elbow, which can be used for designing ventilation pipes, gas delivery pipes and environmental protection ventilation systems. [0002] Background technique [0003] At present, most right-angle elbows are achieved by lapping the edge. For example, right-angle joints used in ventilation ducts. They are all rolled up, which not only wastes a lot of raw materials (galvanized steel sheets), but also makes it difficult to seal the interface due to the existence of the rolled mouth. The right-angle elbow welded by the new technology not only reduces the loss of raw materials, but also improves the sealing performance of the nozzle. [0004] Contents of the invention [0011] The main purpose of the present invention is to provide a butt-welding galvanized elbow which changes the original lap-rolling combination method and adopts a butt-joint method for welding. Technical scheme of the present inven...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16L13/02F16L43/00

Inventor 朱为民

Owner 江苏海德节能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com