Winding method of cored coil and winding device of cored coil

A winding device and a cored coil technology are applied in the field of cored coil windings and cored coil winding devices to achieve the effect of rapid winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

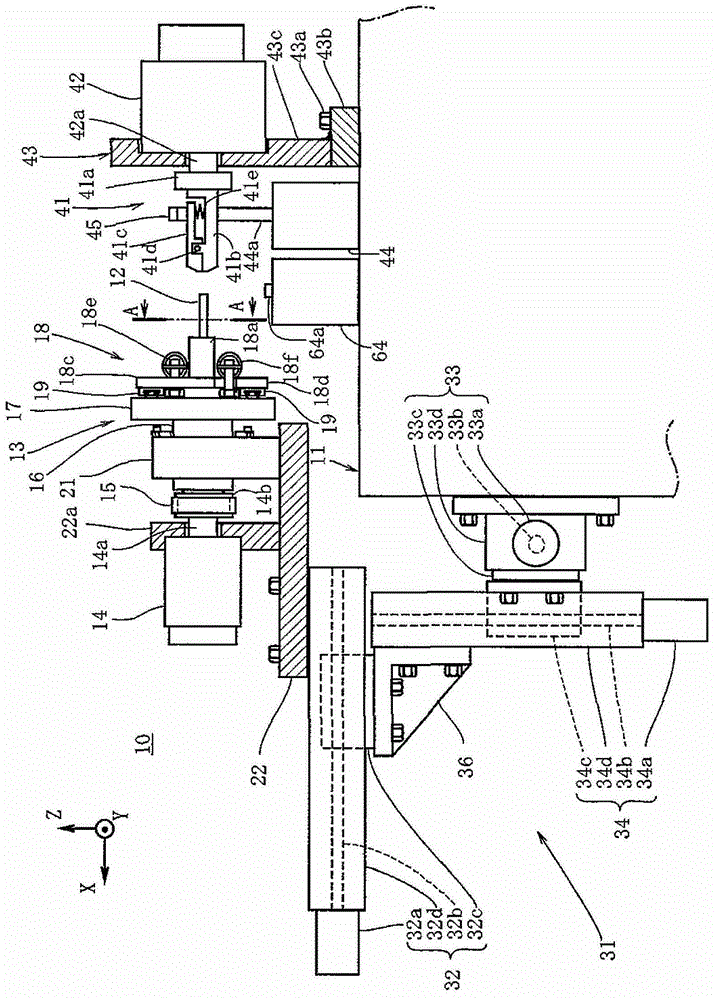

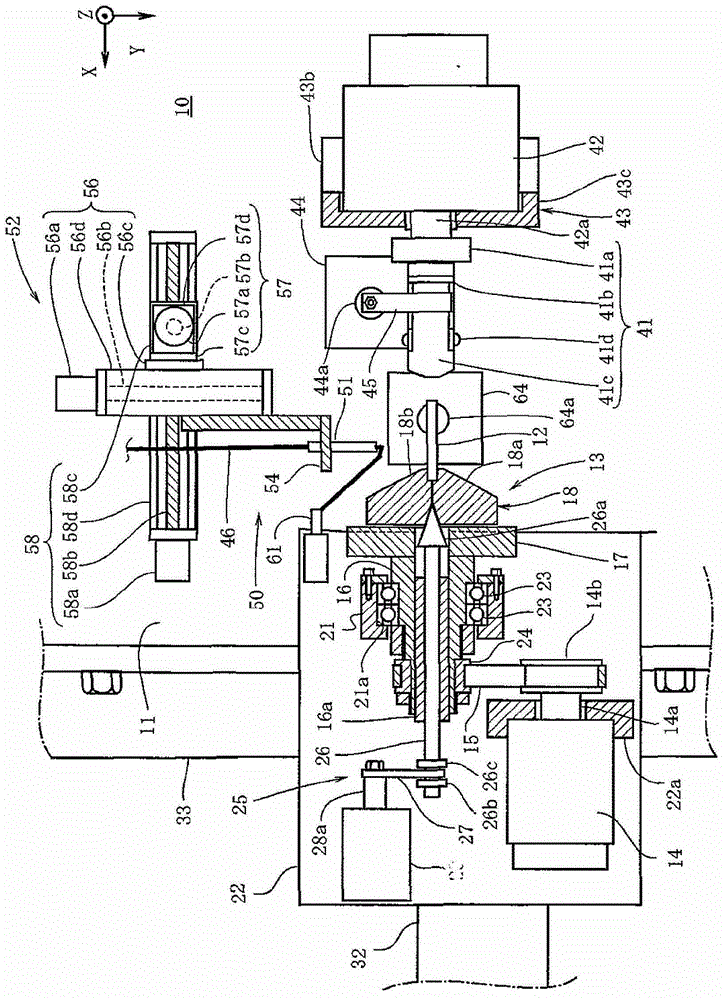

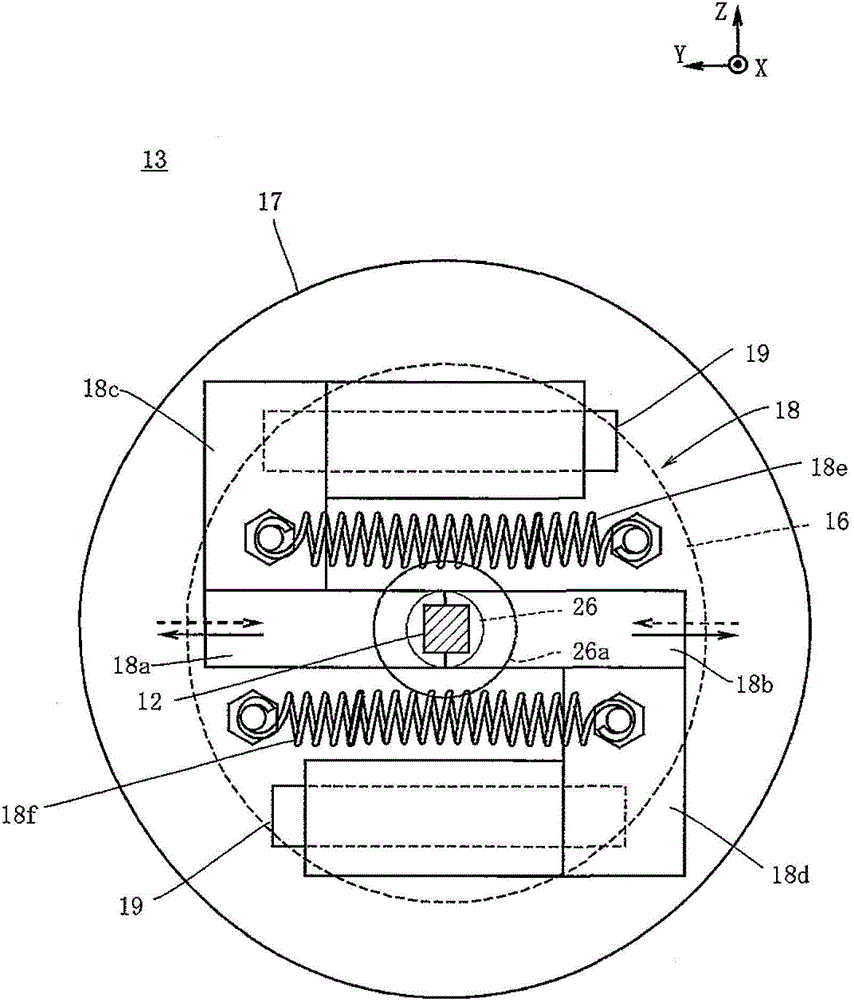

[0027] Next, the best mode for implementing the present invention will be described based on the drawings.

[0028] figure 1 and figure 2 The winding device 10 for the cored coil of the present invention is shown in . Among them, the three axes X, Y, and Z that are orthogonal to each other are set, and the X axis is set to extend horizontally, the Y axis is set to extend along the horizontal front-back direction, and the Z axis is set to extend along the vertical direction. Thus, the winding device 10 of the present invention will be described. The winding device 10 of the present invention includes a base 11 and a first winding jig 13 configured to support one end of a member 12 to be wound and to be rotatable together with the member 12 to be wound. The base 11 is configured in a box shape capable of being installed at an installation location, and a not-shown moving roller and a stopper member for fixing to the installation location are installed at the lower portion. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com