Pixel structure and its manufacturing method

A technology of pixel structure and manufacturing method, applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve problems such as flickering of display screen, insufficient charging of storage capacitor, limitation of light utilization efficiency of products, etc., and achieve the effect of improving storage capacitor value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

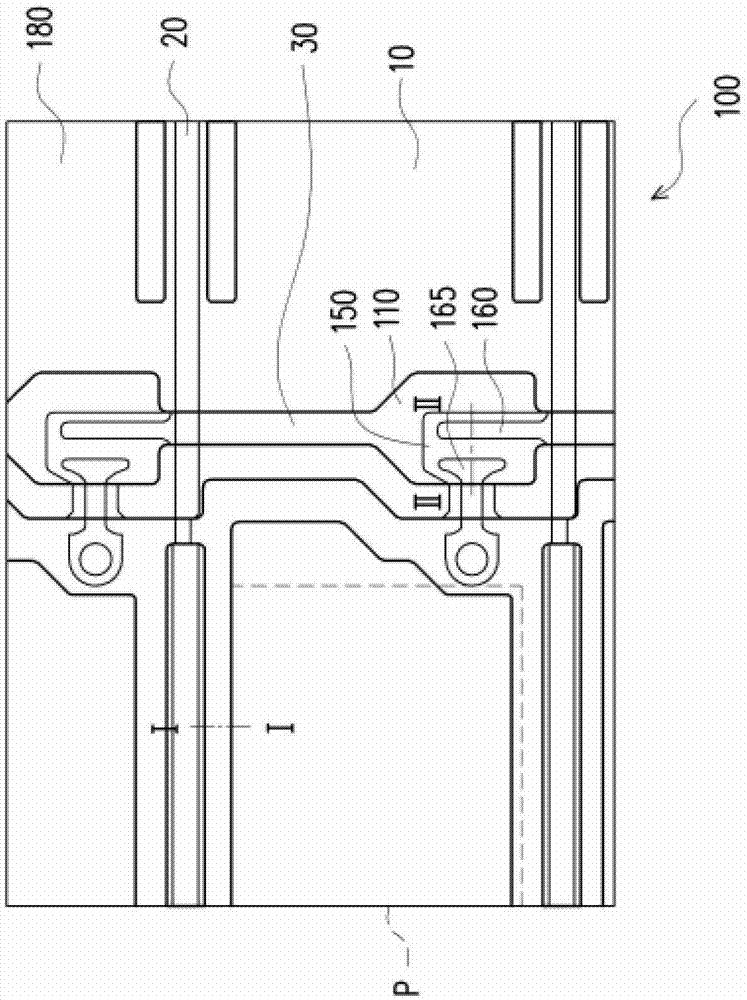

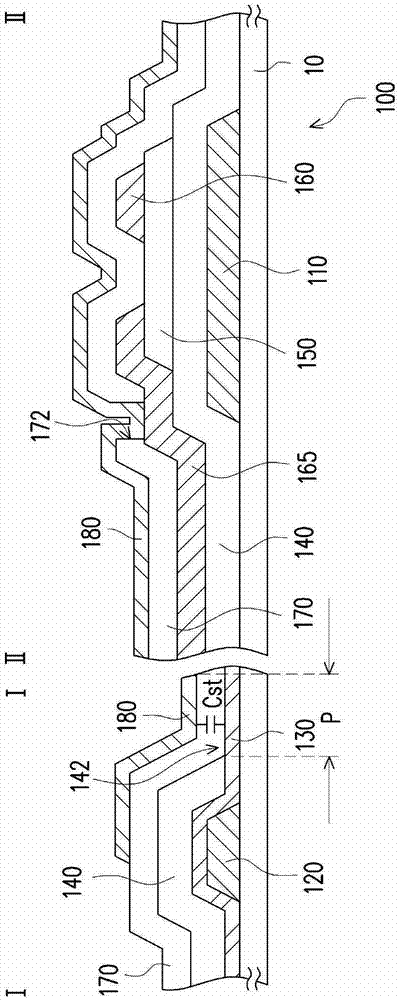

[0041] figure 1 It is a top perspective schematic diagram of a pixel structure according to an embodiment of the present invention. figure 2 shown along figure 1 Schematic cross-sectional view of line I-I and line II-II. Please also refer to figure 1 and figure 2 , in this embodiment, the pixel structure 100 is configured on a substrate 10, wherein the substrate 10 may be a glass substrate, a plastic substrate or a substrate made of other materials. The pixel structure 100 is electrically connected to the scanning line 20 and the data line 30, and the pixel structure 100 includes a gate 110, a capacitor electrode 120, a capacitor transparent electrode 130, a gate insulating layer 140, a semiconductor layer 150, a source 160 , a drain 165 , a protection layer 170 and a pixel electrode 182 .

[0042] In detail, the gate 110 is disposed on the substrate 10 . The capacitor electrode 120 is disposed on the substrate 10 . The capacitive transparent electrode 130 is disposed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com