Array substrate and manufacturing method thereof and liquid crystal display

A technology of array substrates and substrate substrates, which is applied in semiconductor/solid-state device manufacturing, instruments, electric solid-state devices, etc., can solve problems such as large influence of pixel unit aperture ratio, influence on image signal transmission, and reduction of light-transmitting area. Achieve good display quality, increase storage capacitor value, and reduce resistance-capacitance delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

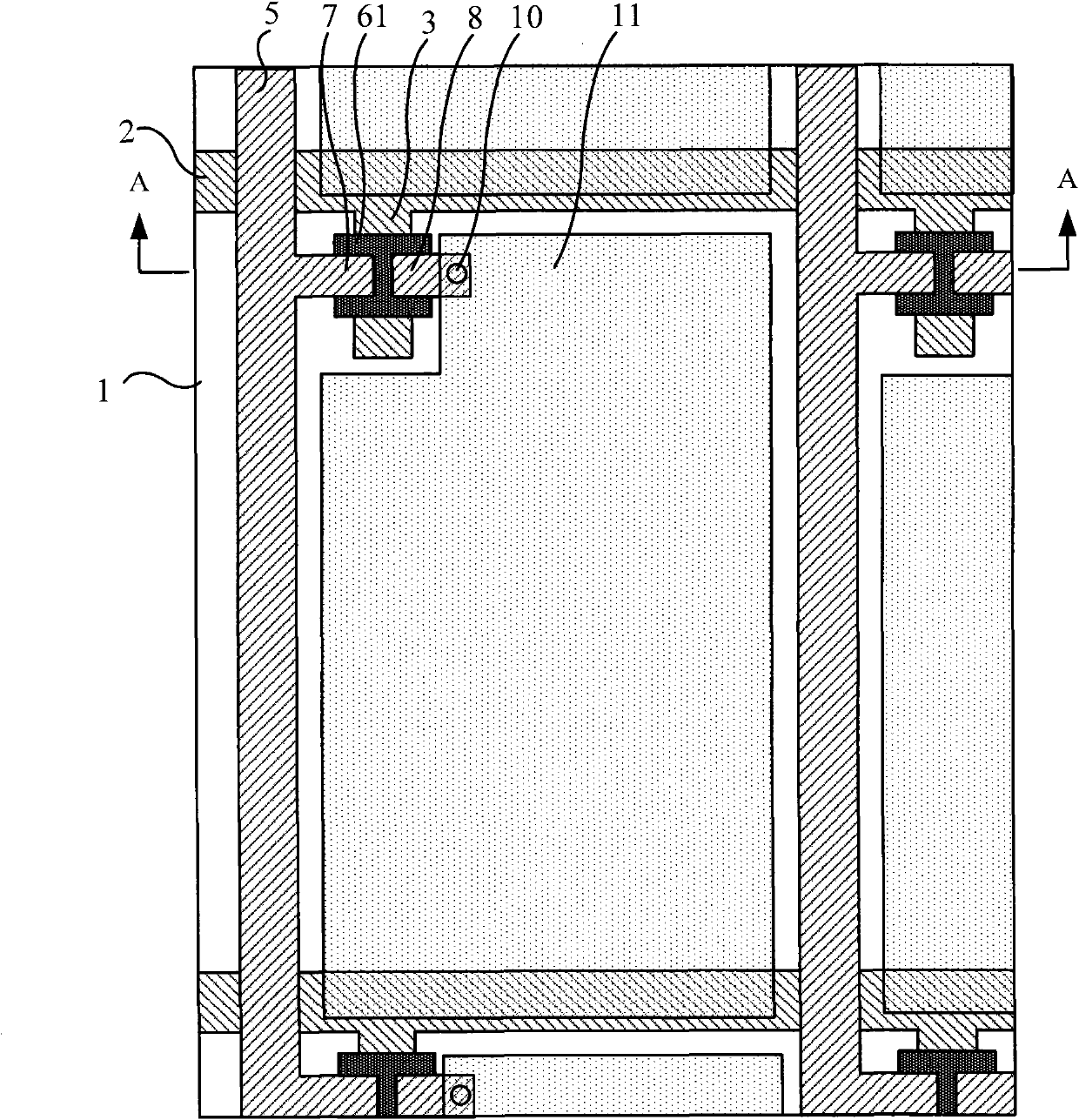

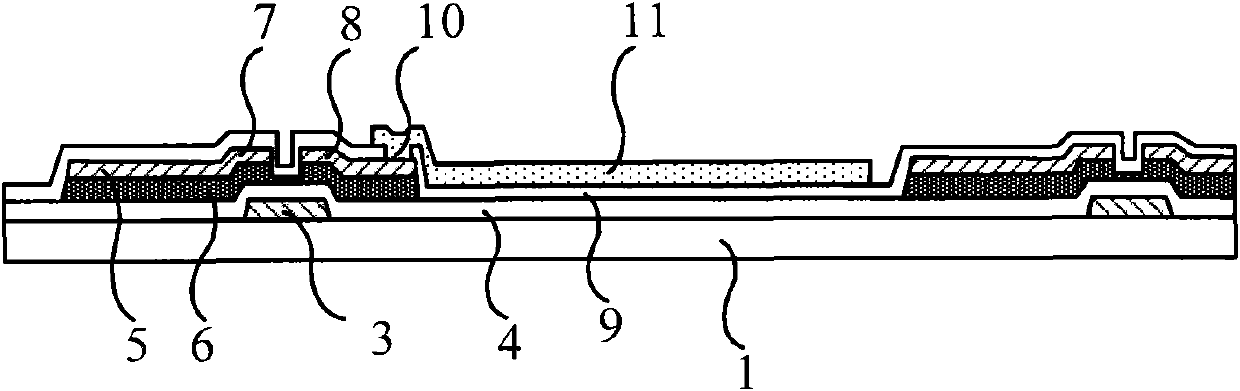

[0044] Figure 3A It is a schematic diagram of a partial top view structure of the array substrate provided in Embodiment 1 of the present invention, Figure 3B for Figure 3A Schematic diagram of the cross-sectional structure in side view along the line C-C. Such as Figure 3A and 3BAs shown, the array substrate includes a base substrate 1; the base substrate 1 is formed with data lines 5 and gate lines 2 that cross vertically and horizontally; the data lines 5 and gate lines 2 surround pixel units arranged in a matrix; each The pixel unit includes a TFT switch and a pixel electrode 11; the TFT switch includes a gate electrode 3, a source electrode 7, a drain electrode 8 and an active layer 6; the gate electrode 3 is connected to the gate line 2, the source electrode 7 is connected to the data line 5, and the drain electrode 8 is connected to The pixel electrode 11 , the active layer 6 are formed between the source electrode 7 and the drain electrode 8 and the gate electr...

Embodiment 2

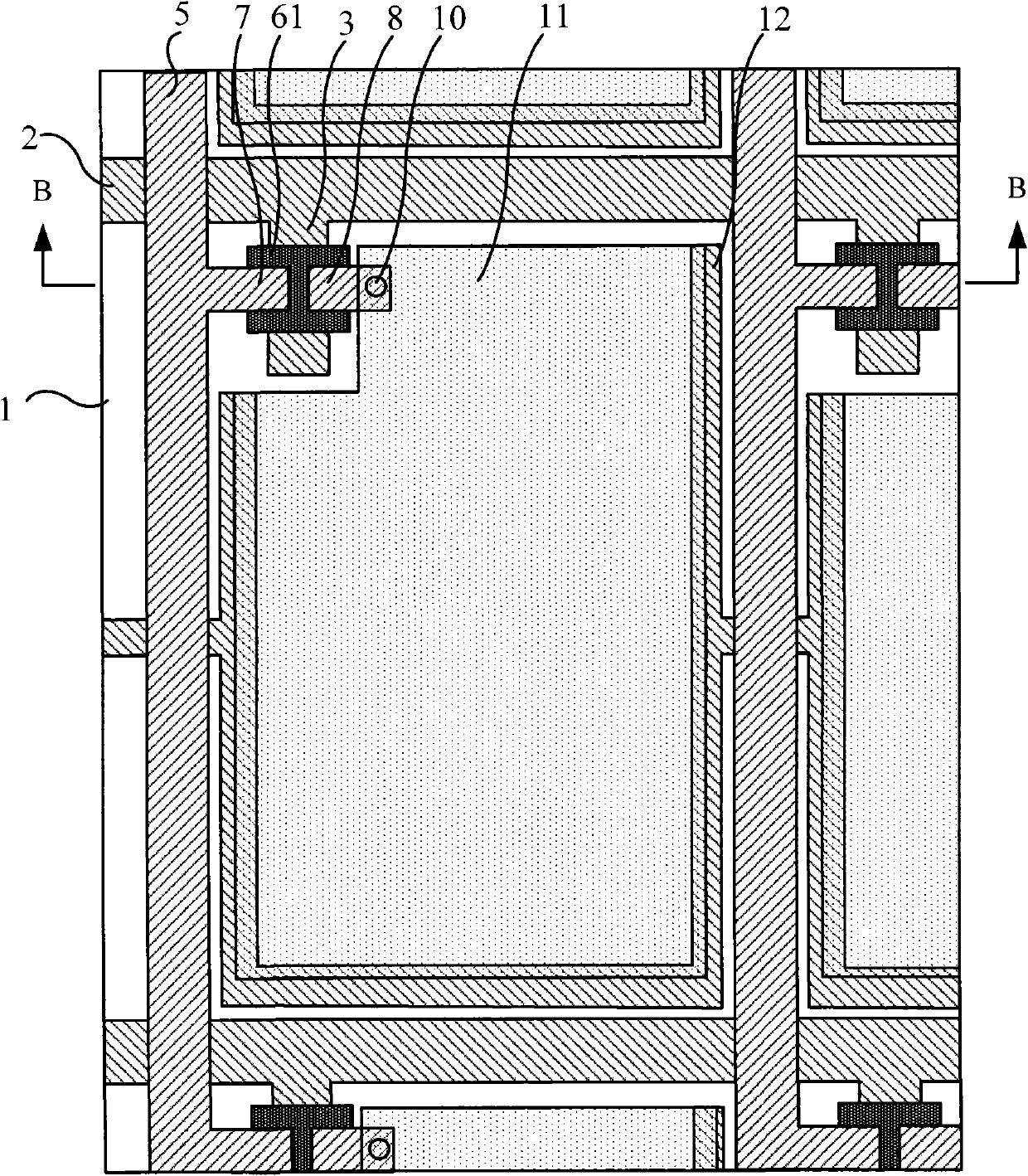

[0051] Figure 4 The partial top-view structural diagram of the array substrate provided by Embodiment 2 of the present invention. The difference between this embodiment and Embodiment 1 is that the additional electrode 13 on each gate line 2 is connected to the common electrode line in two adjacent pixel units. 12 electrical connections. This technical solution can be realized simply by appropriately changing the number and position of the additional via holes, and changing the pattern of the jumper wire 16 .

[0052] The technical solution of this embodiment can not only optimize the storage capacitance, but also connect the adjacent common electrode lines formed in rows through additional electrodes, so as to avoid storing common voltage differences between the common electrode lines of each row, and make the common voltage uniformity in the common electrode lines better. High, this can avoid the flickering phenomenon that occurs in the display process of the pixel unit. ...

Embodiment 3

[0054] Figure 5A It is a schematic diagram of a partial top view structure of the array substrate provided in Embodiment 3 of the present invention, Figure 5B for Figure 5A Schematic diagram of the cross-sectional structure in side view along the line D-D. The difference between the technical solution of this embodiment and the first embodiment is that: the common electrode lines 12 and the data lines 5 are formed in the same layer and the patterns are spaced apart from each other, and the additional electrodes 13 and the common electrode lines 12 are integrally formed.

[0055] The technical solution of this embodiment still has the advantage of increasing the storage capacitance, and can reduce the area of the common electrode line under the premise of forming the same storage capacitance value, thereby increasing the aperture ratio of the pixel unit. In addition, compared with the technical solution of the first embodiment, this embodiment also omits the process of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com