Pixel structure and manufacturing method therefor

A technology of pixel structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, photolithographic process exposure device, optics, etc., can solve problems such as cost increase, achieve simplified steps, high storage capacitance value, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

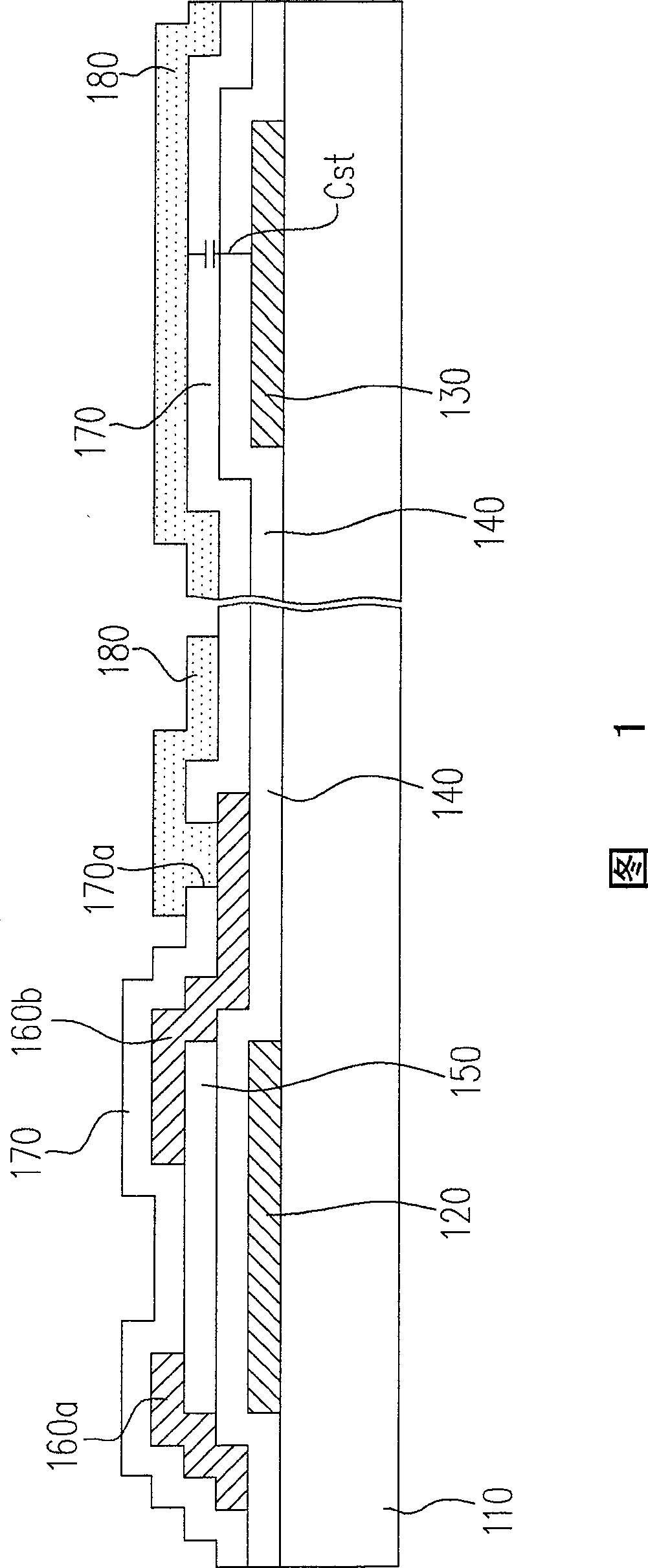

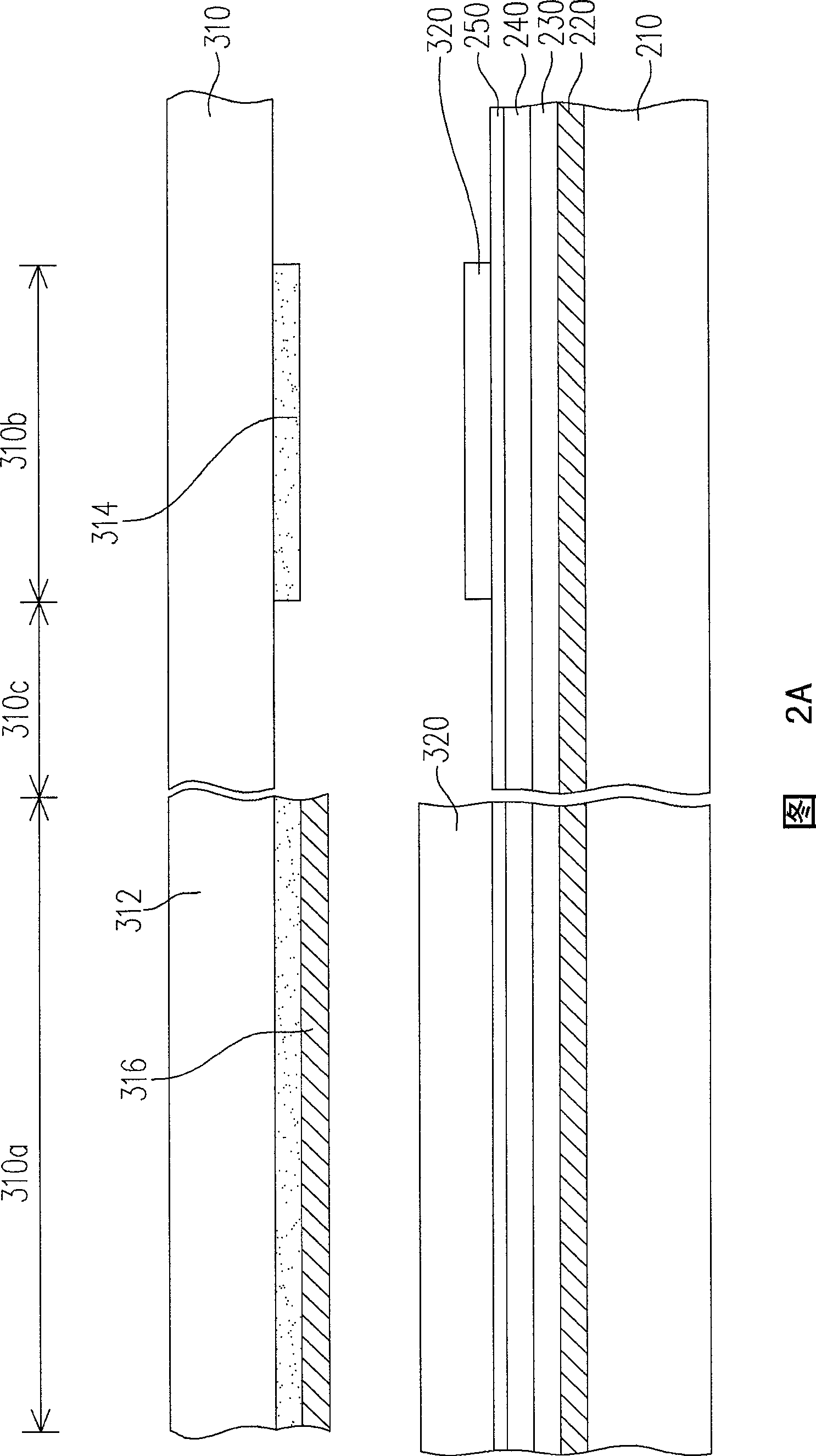

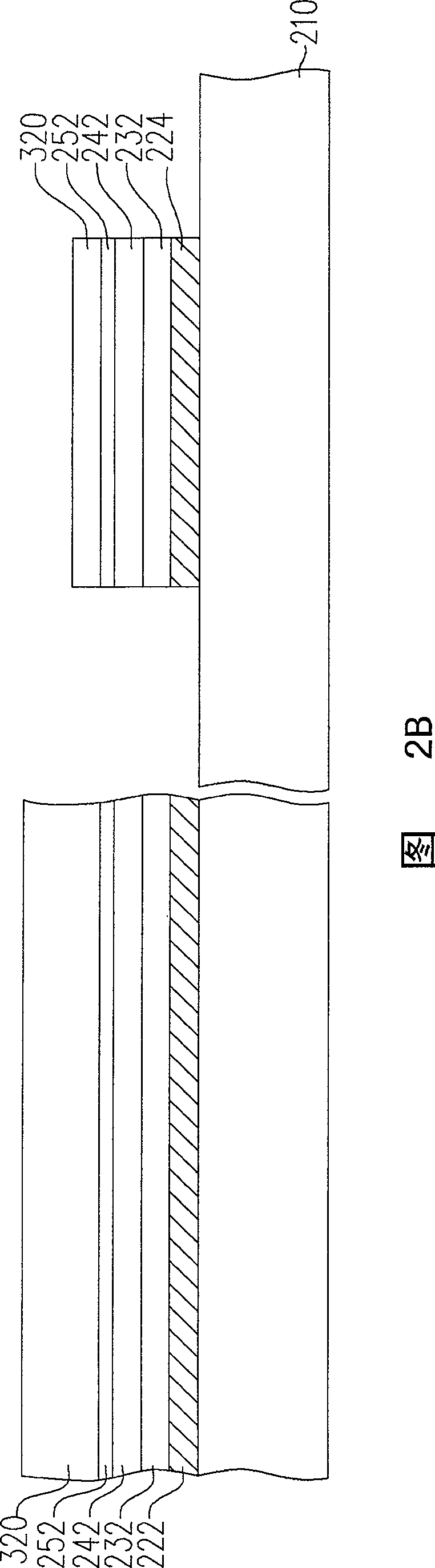

[0056] 2A to 2G are schematic diagrams of a method for manufacturing a pixel structure according to an embodiment of the present invention. Please refer to FIG. 2A , the manufacturing method of the pixel structure in this embodiment includes the following steps. First, a substrate 210 is provided, and a metal layer 220 , a gate insulating layer 230 and a semiconductor material layer 240 are sequentially formed on the substrate 210 . In addition, in order to improve the electrical quality of the device, an ohmic contact material layer 250 may also be formed on the semiconductor material layer 240 .

[0057] Then, a mask 310 is provided, and the mask 310 is, for example, a halftone mask. In addition, the mask 310 includes a transparent substrate 312 , a semi-transmissive film 314 and a light shielding layer 316 . Wherein, the semi-transmissive film 314 is disposed on the transparent substrate 312, and the light-shielding layer 316 is disposed on the semi-transparent film 314, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com