Heat dissipation module and its configuration method

A technology of heat dissipation module and structure, which is applied in the direction of cooling/ventilation/heating transformation, etc. It can solve the problems of high thermal resistance of heat pipes and heat dissipation fins, and the inability to effectively use heat dissipation fins to dissipate heat, so as to reduce heat resistance and improve heat dissipation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

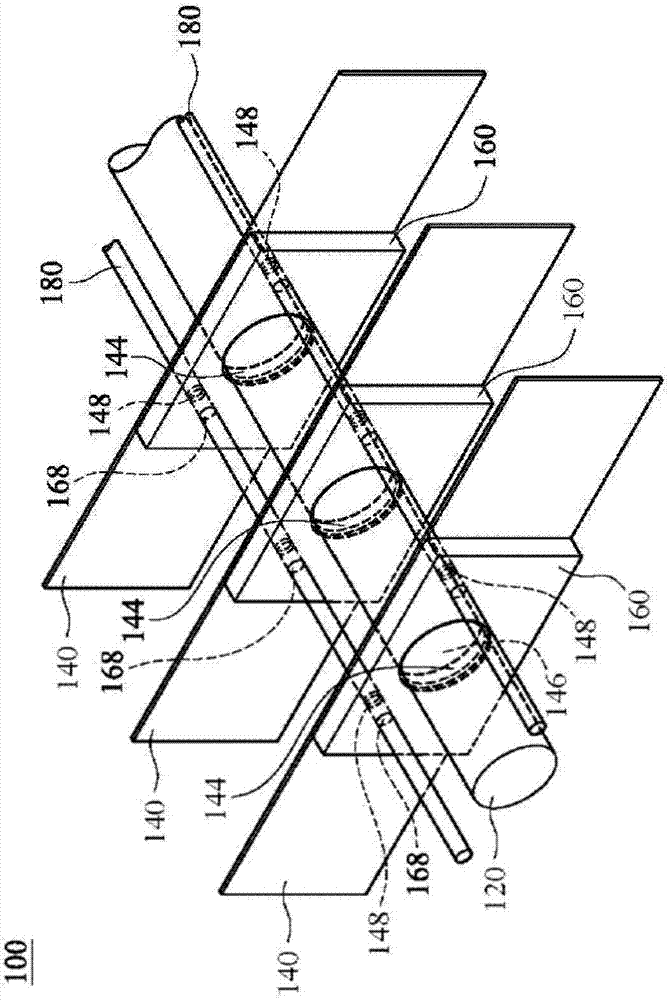

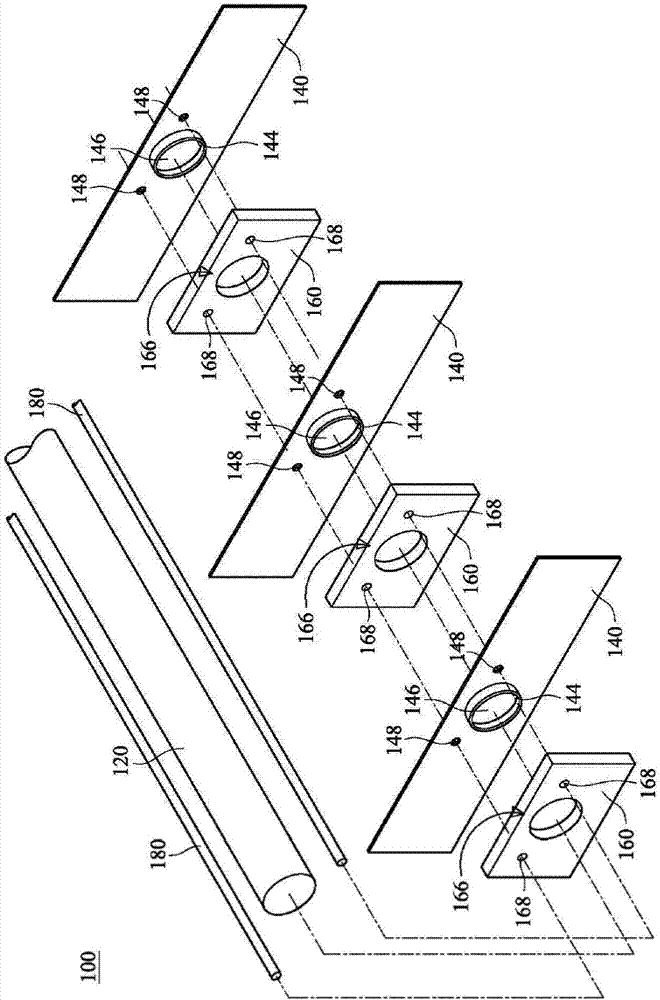

[0052] see figure 1 and figure 2, are respectively a three-dimensional assembled view and a three-dimensional exploded view of the heat dissipation module 100 according to an embodiment of the present invention. The function of the heat dissipation module 100 disclosed in this embodiment of the present invention is to press the extension part 144 of the heat dissipation fin 140 by pressing the clip 160, so that the extension part 144 is partially recessed into the outer surface of the heat pipe 120 to face The heat pipe 120 forms a clamping force, thereby enhancing the heat dissipation performance of the heat dissipation module 100 of the present invention.

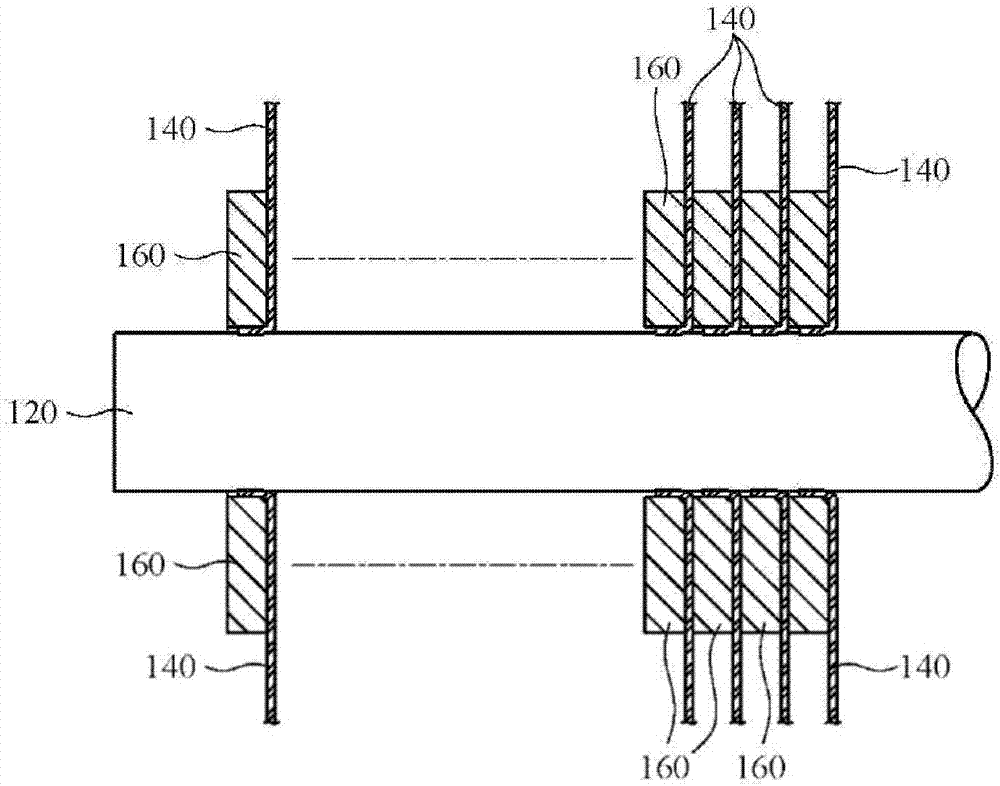

[0053] image 3 Shown is a schematic plan view of a heat dissipation module 100 according to an embodiment of the present invention, Figure 4 for image 3 A partial enlargement of the . In detail, the heat dissipation module 100 according to an embodiment of the present invention includes a heat pipe 120 , a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com