Traction control unit and control box

A traction control unit and control instruction technology, which is applied in the direction of control drive, electric vehicles, locomotives, etc., can solve the problems that the traction control unit technology is not fully mastered, and achieve good adhesion utilization and anti-idling performance, high power factor, and harmonic less distracting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

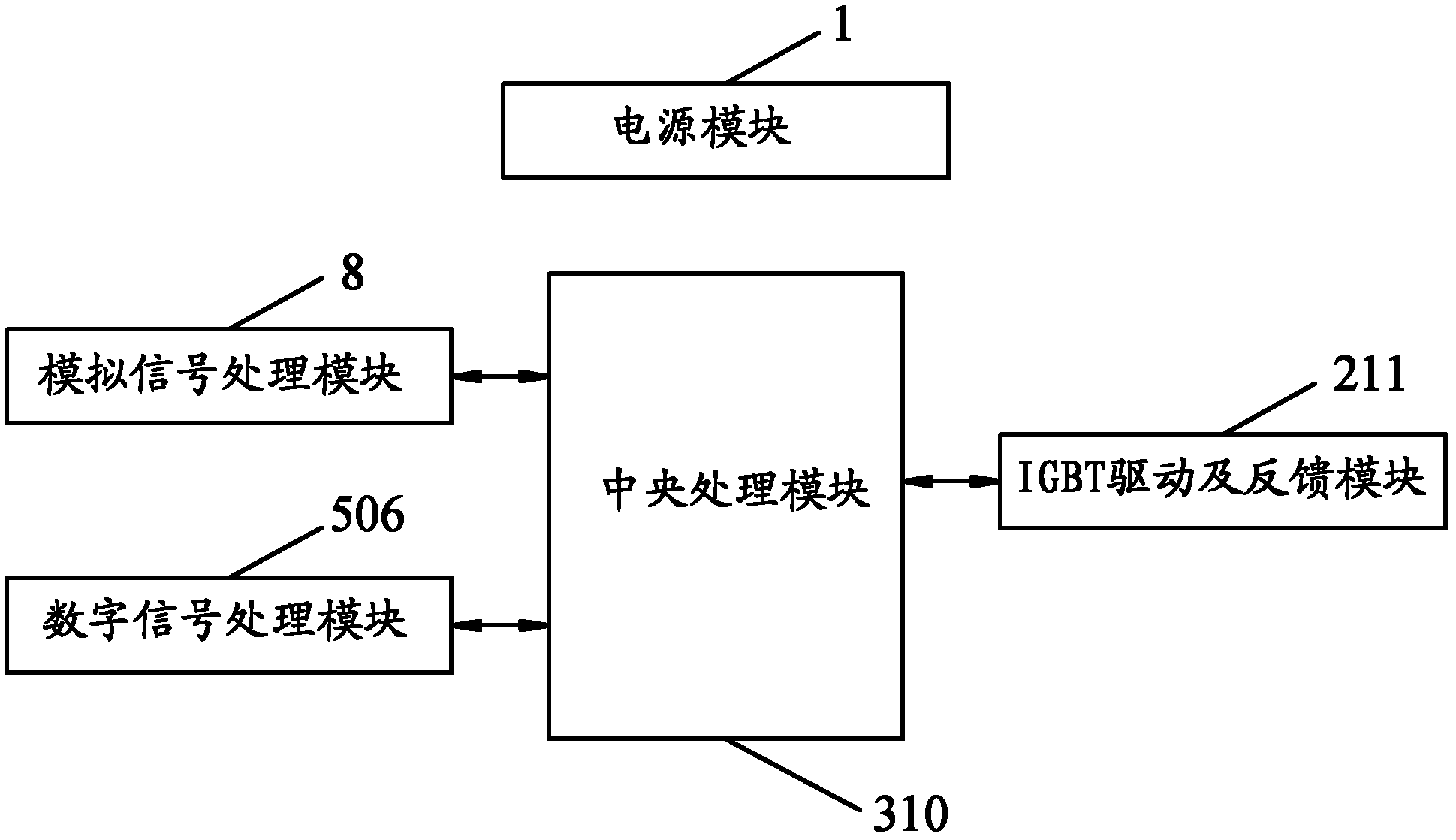

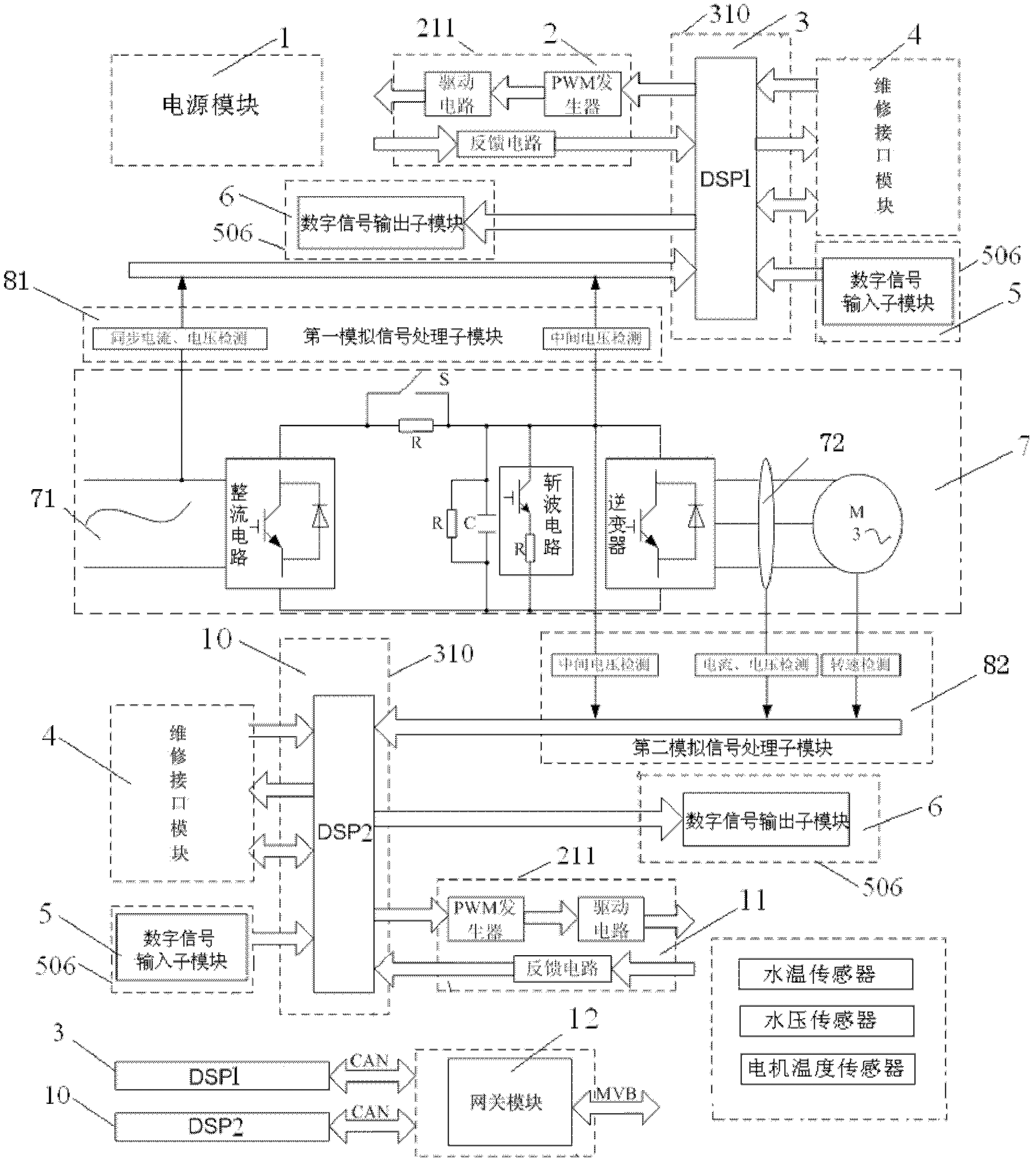

[0018] The first embodiment of the traction control unit provided by the present invention. Such as figure 1 As shown, the traction control unit of this embodiment includes: a power module 1, an analog signal processing module 8, a digital signal processing module 506, a central processing module 310, and an IGBT (Insulated Gate Bipolar Transistor, insulated gate bipolar transistor) drive and Feedback module 211. The control instruction receiving end of the digital signal processing module 506 is communicatively connected with the control instruction output end of the central processing module 310; the signal receiving end of the central processing module 310 is respectively connected to the analog signal processing module 8 and the digital signal processing module 8 The output terminal of the module 506 is communicatively connected; the monitoring fault access terminal of the central processing module 310 is communicatively connected to the feedback fault signal output termina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com