Automatic cover removal and sealing system for nuclear waste material steel drum

A technology for nuclear waste and barrel covers, which is applied in the directions of closures, nuclear engineering, threaded cover disassembly, etc., can solve problems such as inability to use, and achieve the effect of avoiding manual intervention and meeting safety requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

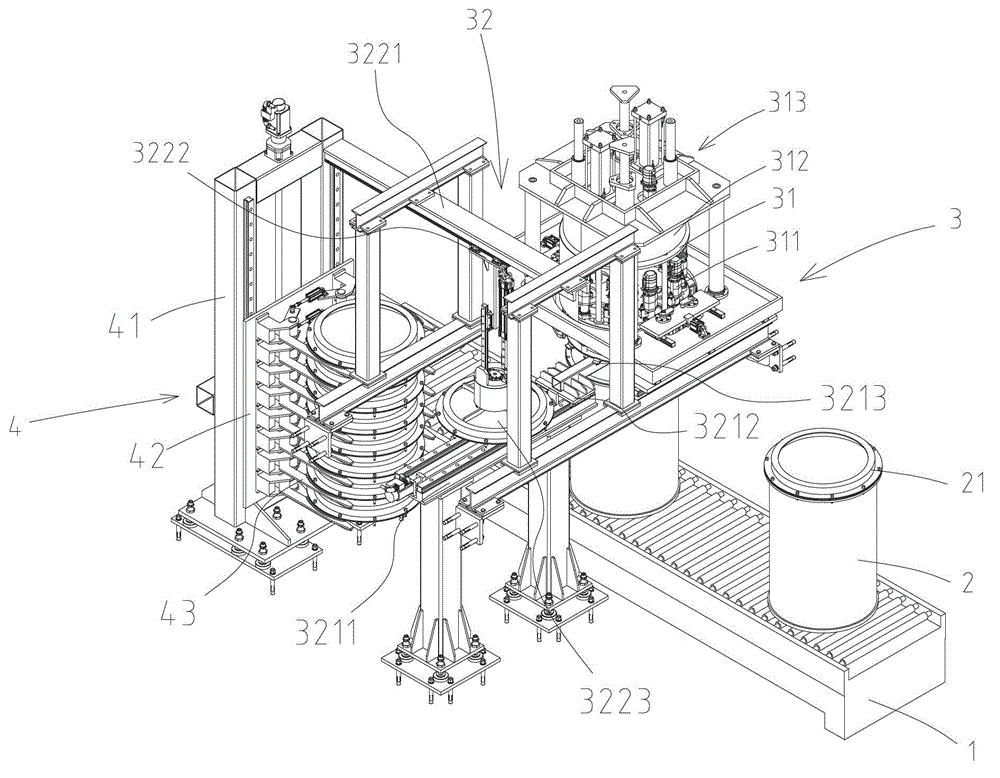

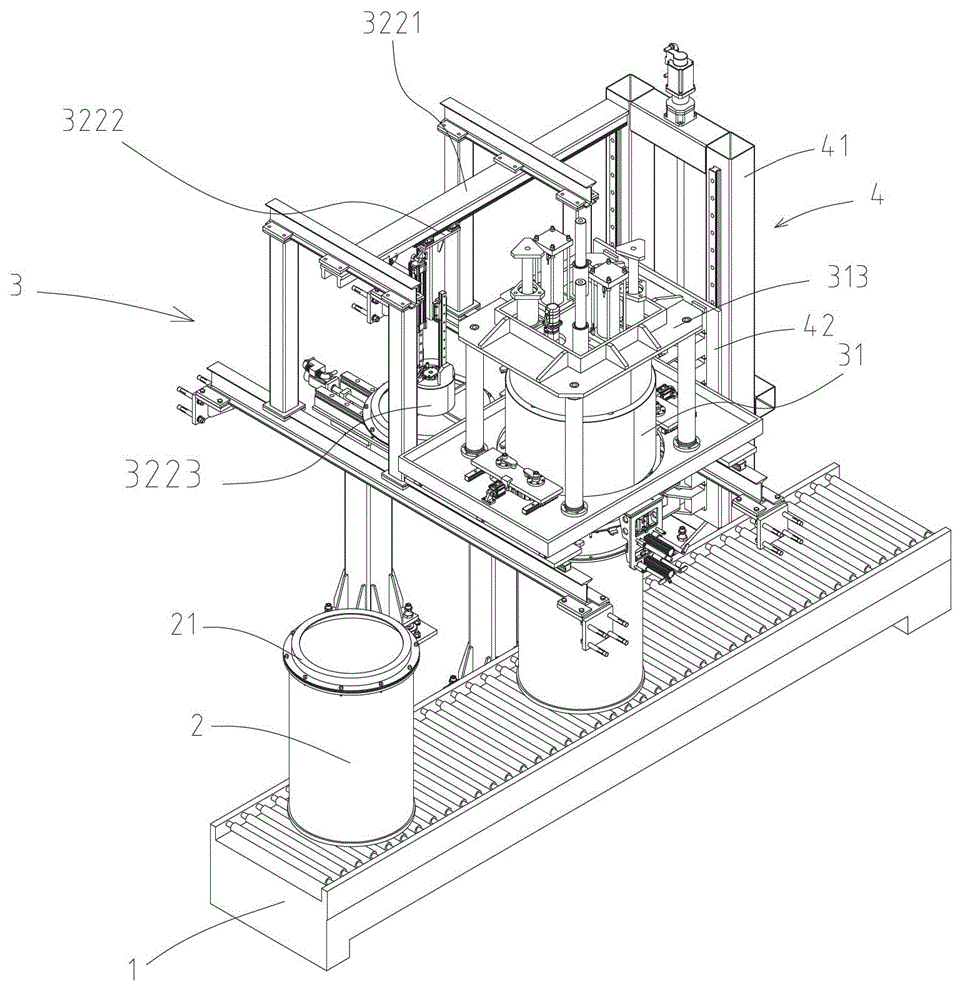

[0028] Such as Figure 1-4 As shown: an automatic capping system for nuclear waste steel drums, which mainly includes: a conveying raceway 1 , a cap grabbing device 3 and a cap storage rack 4 .

[0029] The conveying raceway 1 conveys the nuclear waste or empty steel drum 2 to the lower part of the device's lid grabbing device 3, and after the lid is removed or sealed, the steel drum 2 is conveyed to other stations.

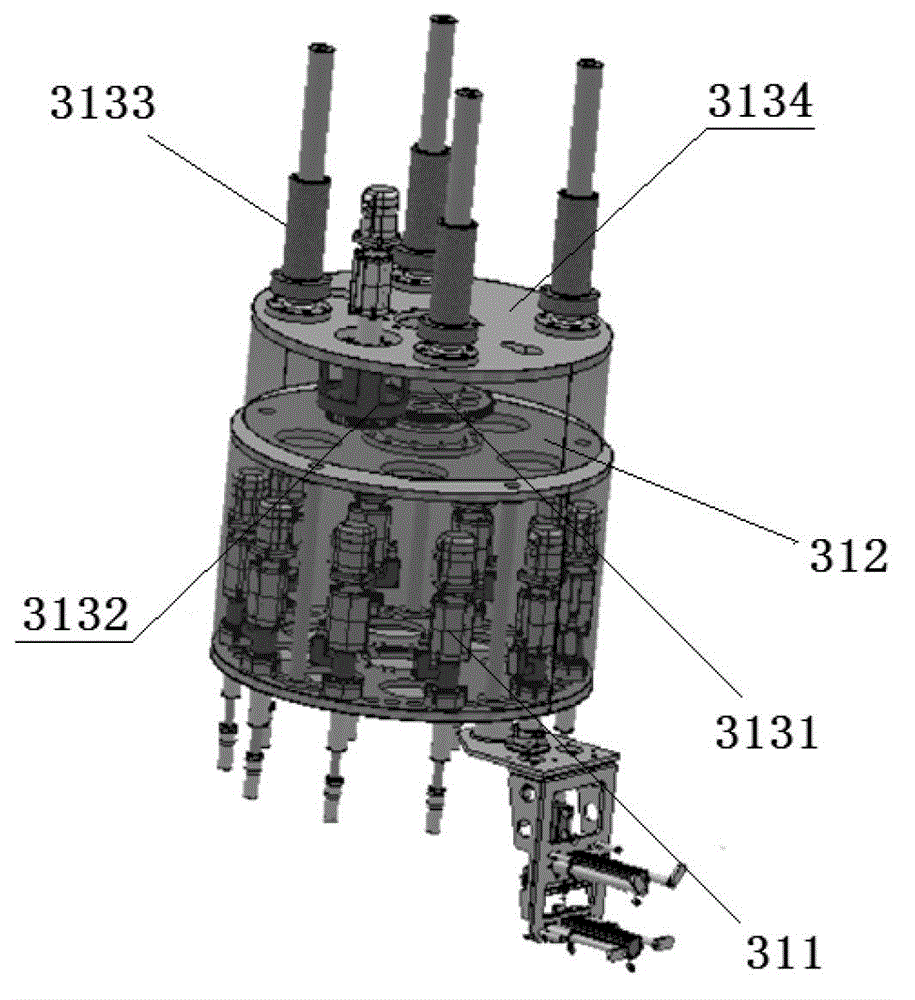

[0030] The lid removing / sealing device 3 is mainly used to complete the actions of centering the steel drum and its own related equipment, installing or removing the drum lid 21 . In order to achieve the above functions, the cap removing / capping dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com