Tri-displacement cooking method

A technology for replacing cooking and cooking pots, which is applied in textiles, papermaking, and fiber raw material processing. It can solve the problems of increasing equipment manufacturing and maintenance costs, achieve significant energy saving and chemical saving, increase the amount of pots installed, and shorten the replacement path. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

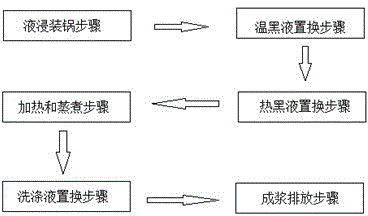

[0037]A three-displacement cooking method, comprising the following steps:

[0038] Liquid immersion filling step: put the tablet into the cooking pot, and when the tablet is loaded, start to deliver the prepreg into the cooking pot. The liquid process ends, and the blank loading process and the prepreg liquid delivery process end at the same time;

[0039] Warm black liquor replacement step: use the warm black liquor from the upper part of the warm black liquor tank to replace the presoak liquid in the cooking pot, and after the replacement, the temperature of the liquid in the cooking pot is raised to 110°C;

[0040] Hot black liquor replacement step: use hot black liquor to replace warm black liquor in the cooking pot, after replacement, the temperature of the liquid in the cooking pot is raised to 140°C;

[0041] Heating and cooking steps: use 0.9MPa medium-pressure steam to heat the feed liquid in the cooking pot after the hot black liquor replacement step to the preset ...

Embodiment 2

[0053] A three-displacement cooking method, comprising the following steps:

[0054] Liquid immersion filling step: put the tablet into the cooking pot, and when the tablet is loaded, start to deliver the prepreg into the cooking pot. The liquid process ends, the tablet loading process and the prepreg liquid delivery process do not end at the same time, and the tablet loading process ends 5-10 minutes earlier than the prepreg liquid delivery process;

[0055] Warm black liquor replacement step: use the warm black liquor from the upper part of the warm black liquor tank to replace the presoak liquid in the cooking pot, after the replacement, the temperature of the liquid in the cooking pot is raised to 125°C;

[0056] Hot black liquor replacement step: use hot black liquor to replace warm black liquor in the cooking pot, after replacement, the temperature of the inner material liquid in the cooking pot is raised to 150°C;

[0057] Heating and cooking steps: use 1.0MPa medium p...

Embodiment 3

[0069] A three-displacement cooking method, comprising the following steps:

[0070] Liquid immersion filling step: put the tablet into the cooking pot, and when the tablet is loaded, start to deliver the prepreg into the cooking pot. The liquid process ends, the blank loading process and the prepreg liquid delivery process do not end at the same time, and the blank loading process ends 5-10 minutes later than the prepreg liquid delivery process;

[0071] Warm black liquor replacement step: use the warm black liquor at the upper part of the warm black liquor tank to replace the presoak liquid in the cooking pot, and after the replacement, the temperature of the liquid in the cooking pot is raised to 140°C;

[0072] Hot black liquor replacement step: use hot black liquor to replace warm black liquor in the cooking pot, after replacement, the temperature of the inner material liquid in the cooking pot is raised to 160°C;

[0073] Heating and cooking steps: Use medium-pressure s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com