Preparation method of hybrid fiber reinforced resin matrix composite 3D printing wire

A technology of reinforcing resin base and hybrid fibers, applied in the direction of coating, etc., can solve the problems of limiting the development and application of 3D printing and the lack of 3D printing filament preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

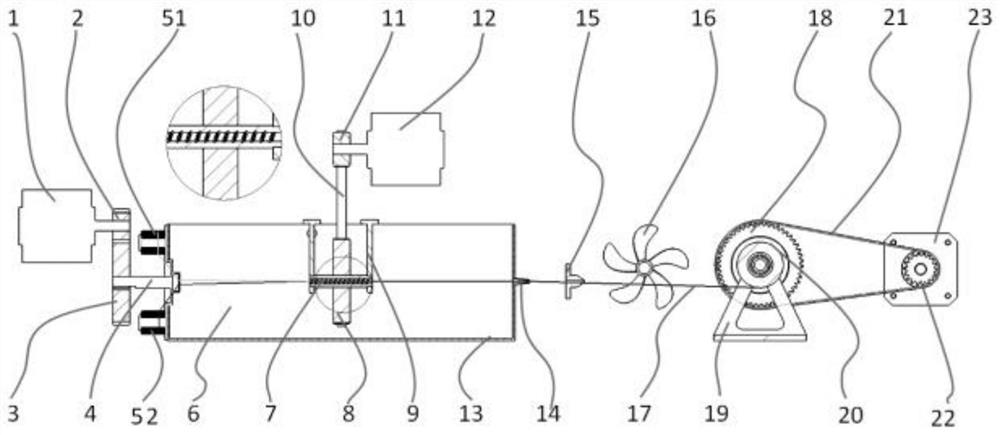

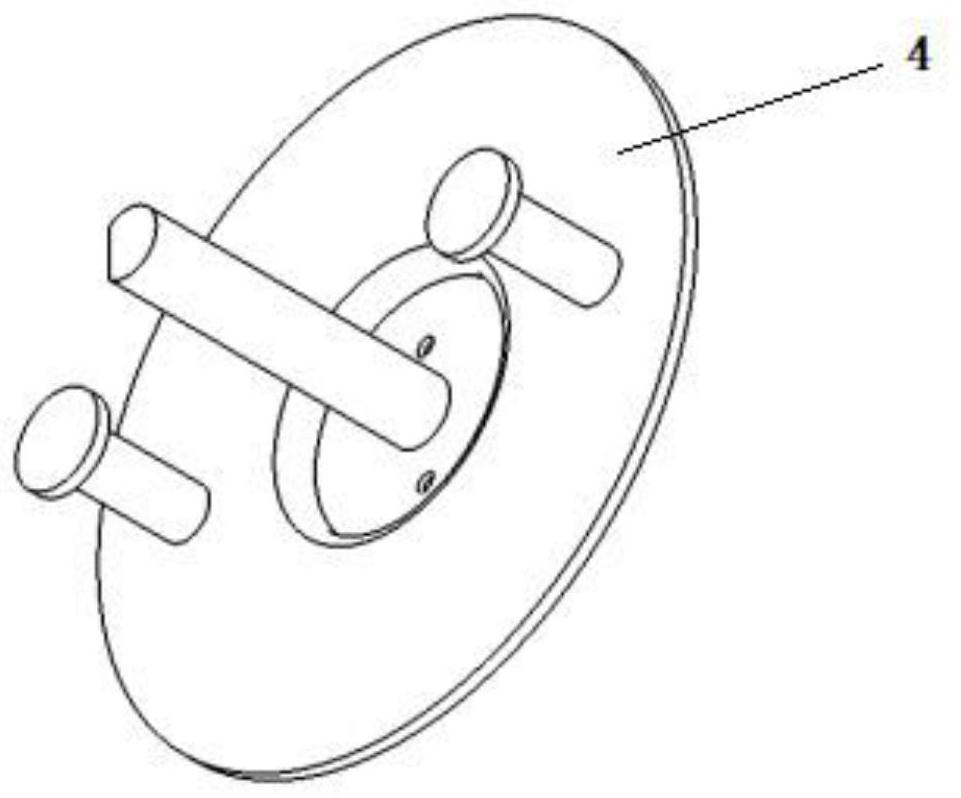

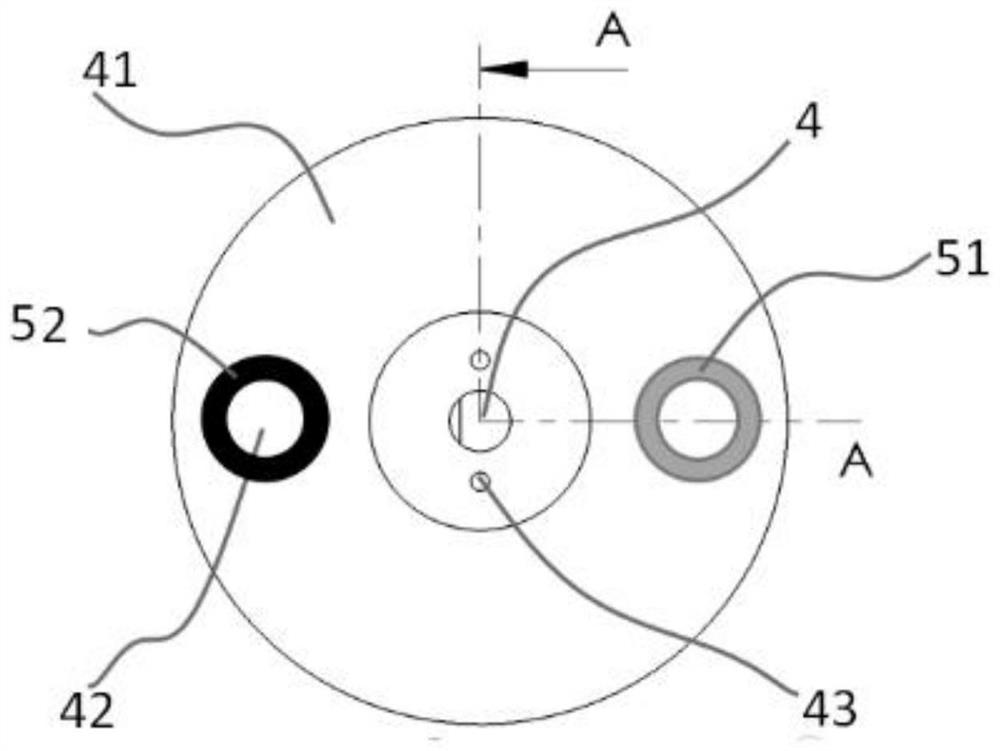

[0033] Embodiment 1, with reference to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a kind of equipment used in the preparation method of hybrid fiber reinforced resin-based composite material 3D printing wire, including a first motor 1, the output shaft of the first motor 1 is connected with a first gear 2, the first gear 2 and the second gear 3 meshing, the second gear 3 is installed on the central axis of the fiber spool seat 4, the fiber spool seat 4 includes a fiber spool seat disc 41, two fiber spools 42 are arranged on the outer side of the fiber spool seat disc 41, and the fiber The inner side of the spool seat disc 41 is provided with more than two guide holes 43; the first dry fiber filament 51 and the second dry fiber filament 52 pass through the guide hole 43 and enter the inside of the resin solution tank 13, and the resin solution tank 13 contains Put resin solution 6;

[0034]The inside of the resin solution tank 13 is provided with a drum 7,...

Embodiment 2

[0042] Embodiment 2, a method for preparing hybrid fiber-reinforced resin-based composite material 3D printing filaments, the equipment used is the same as that of Embodiment 1 except that the structure of the fiber spool seat 4 is different, including the following steps:

[0043] 1) if figure 1 , Image 6 As shown, there are 3 fiber spools 42 and 3 guide holes 43 on the fiber spool seat 4, and the second dry fiber filaments 52 of two carbon fibers and the first dry filament 51 of a glass fiber are respectively wound clockwise onto the fibers. On the spool 42, the second dry fiber filament 52 and the first dry fiber filament 51 are respectively passed through the three guide holes 43 on the fiber spool seat 4. Since the dry fiber filament is in a tense state, the dry fiber filament will be transmitted A certain pulling force is given to the fiber spool 4, so that a clockwise moment will be formed for the fiber spool seat 4, and the dry fiber thread enters the inside of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com