Steel product production control method based on consumption forecast

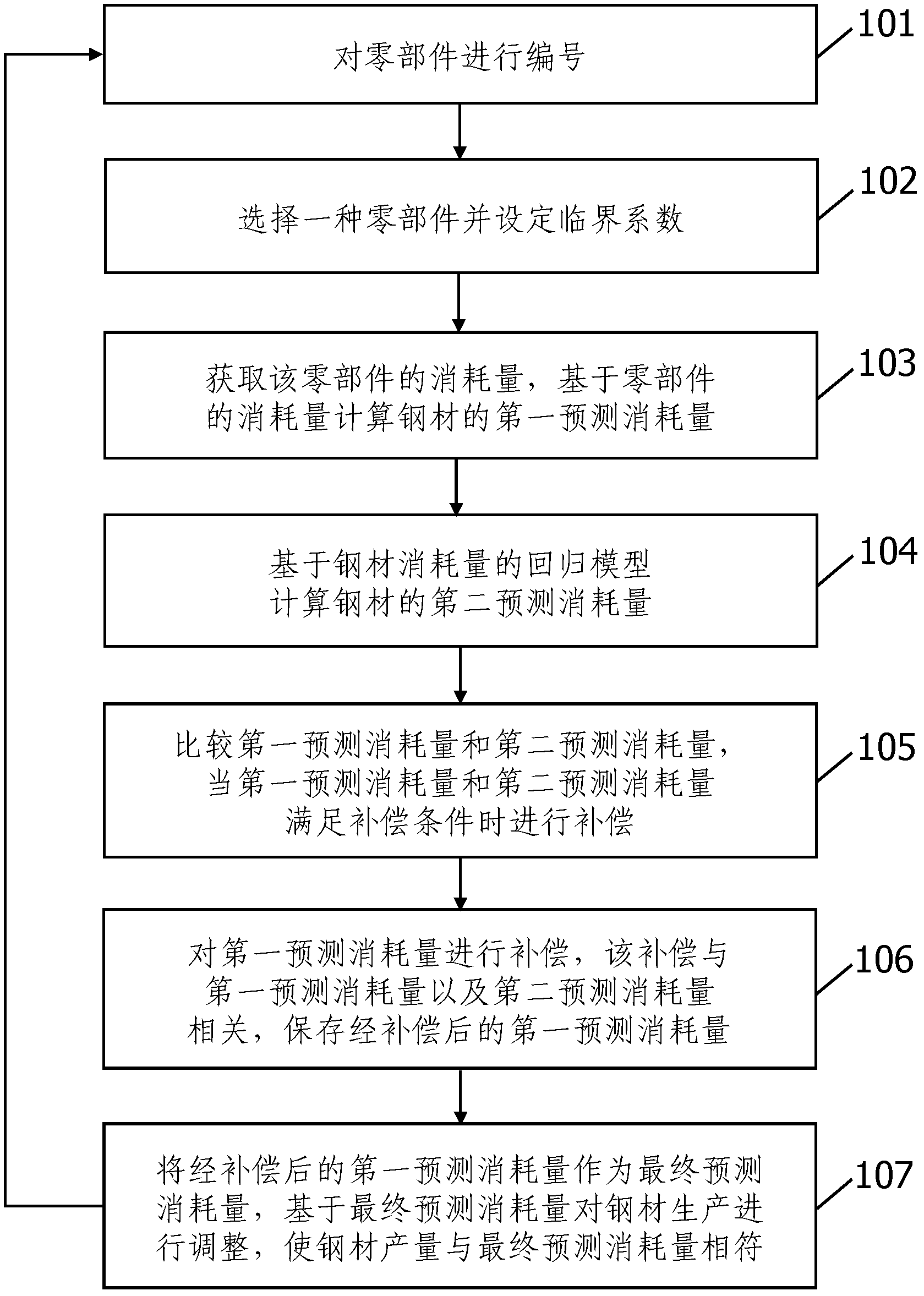

A production control method and consumption technology, applied in forecasting, manufacturing computing systems, instruments, etc., can solve problems such as inaccurate forecasting, lack of modeling, and inability to combine historical data with real-time information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

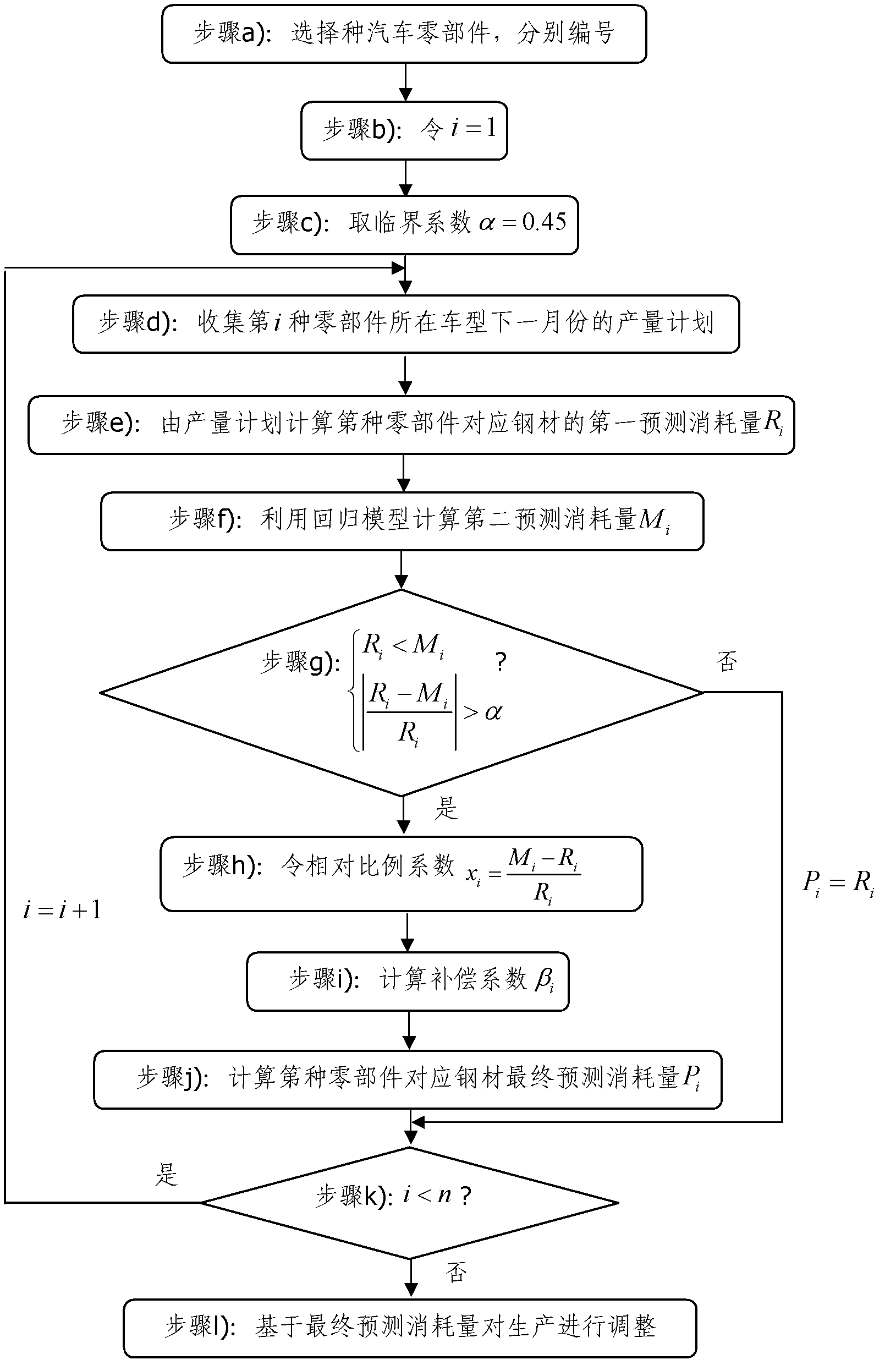

[0065] In step a), select 4 kinds of auto parts, which are rear door outer panel, rear door floor, front door outer panel and front door floor, numbered i=1, 2, 3, 4.

[0066] In step b), set the auto part number i=1, that is, select the outer panel of the rear door for calculation.

[0067] In step c), the critical coefficient α=0.45 is taken.

[0068] In step d), the production plan for the model A in which the first type of component is located is 17,800 in the next month (May).

[0069] In step e), the first predicted consumption of steel corresponding to the first type of component (ie, rear door outer panel) is calculated from the production plan of A model 1 It is 845 tons of hot-dip galvanized sheets of certain specifications.

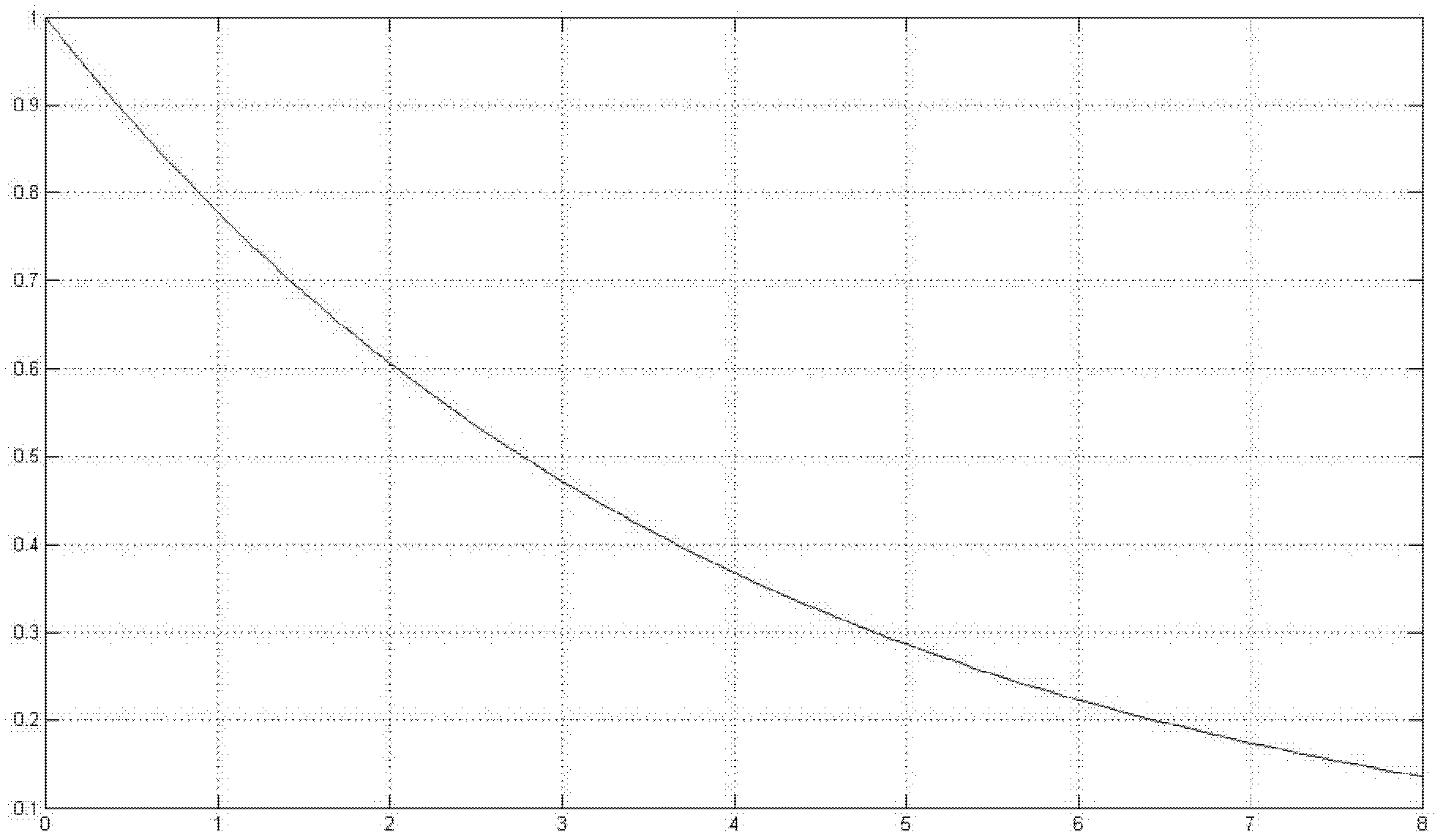

[0070] In step f), use this kind of steel consumption regression model to calculate the second predicted consumption M in May i , the regression model of the first type of component (that is, the outer panel of the rear door) is y=-0.109x 5...

no. 2 example

[0078] In step a), select 6 kinds of auto parts, which are respectively the upper part of the left beam, the lower part of the left beam, the upper part of the right beam, the lower part of the right beam, the left part of the upper part of the control arm and the right part of the upper part of the control arm, and the number i= 1, 2, 3, 4, 5, 6.

[0079] In step b), let the auto part number i=1, that is, select the upper piece of the left beam for calculation.

[0080] In step c), the critical coefficient α=0.45 is taken.

[0081] In step d), the production plan for the model B of the first type of component (that is, the upper piece of the left beam) in the next month (July) is 15,470 units.

[0082] In step e), the first predicted consumption R of steel corresponding to the first type of component is calculated by the production plan 1 It is 580 tons of 0.65mm×885mm cold-rolled steel plate.

[0083] In step f), the consumption regression model of this kind of steel is u...

no. 3 example

[0089] In step a), 5 kinds of auto parts are selected, namely the left spring seat, the right spring seat, the upper part of the rear axle, the lower part of the rear axle and the lower part of the control arm, and the numbers i=1, 2, 3, 4, 5.

[0090] In step b), let the auto part number i=1, and select the left spring seat for calculation.

[0091] In step c), the critical coefficient α=0.45 is taken.

[0092] In step d), the production plan for the model C of the first type of component (that is, the left spring seat) in the next month (August) is 23,760 units.

[0093] In step e), the first predicted consumption R of steel corresponding to the first type of component (that is, the left spring seat) is calculated by the production plan 1 It is 710 tons of 0.75mm×1145mm electro-galvanized sheet.

[0094] In step f), the second predicted consumption M in August is calculated according to the regression model i , the regression model of the first type of component (that is,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com