Peeling device

A stripping device and stripping part technology, which is applied in the direction of electrical components, circuits, connections, etc., can solve problems such as difficulty for personnel to stand up and potential safety hazards for personnel, and achieve the effects of simplifying workload, improving efficiency, and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

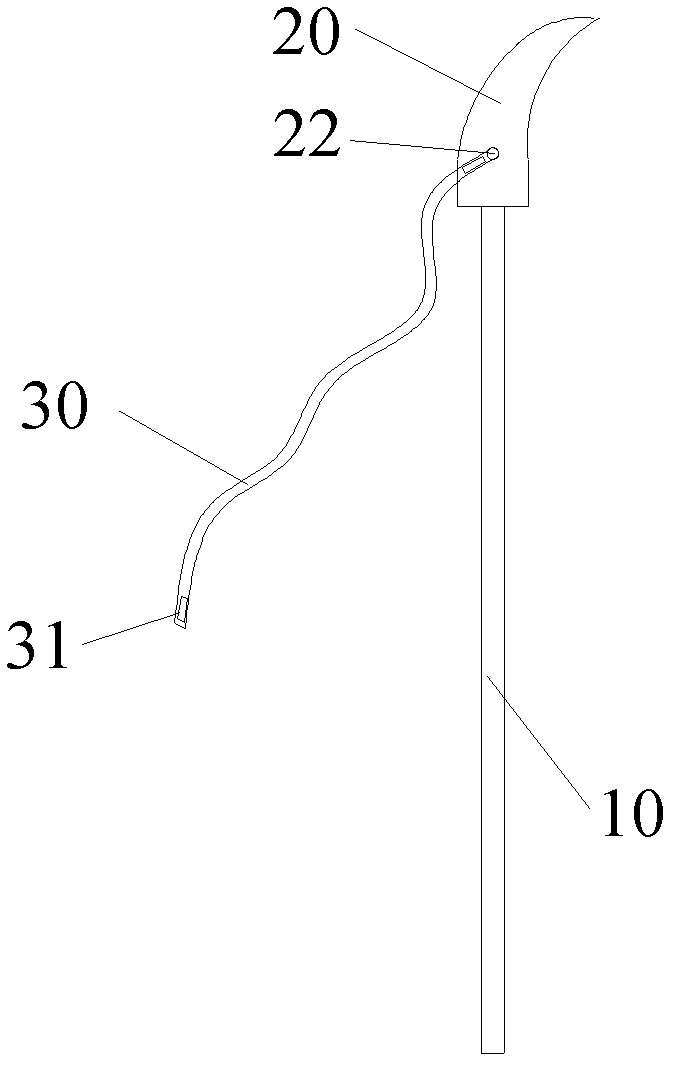

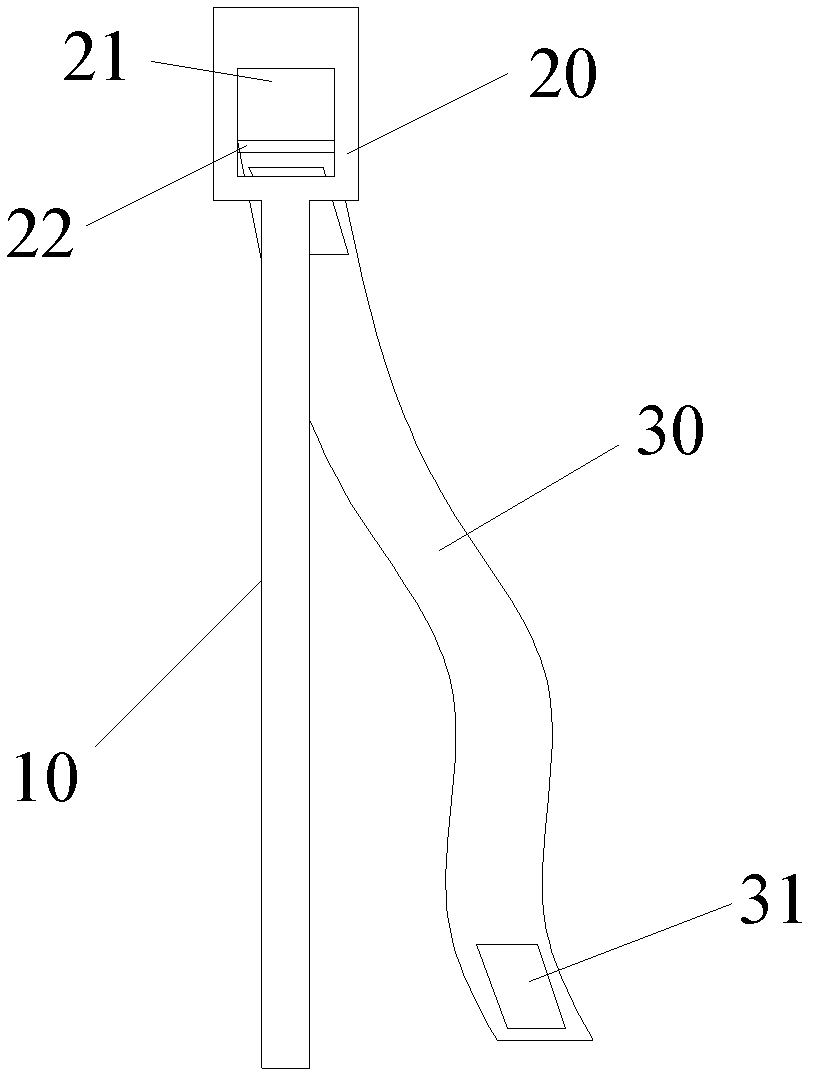

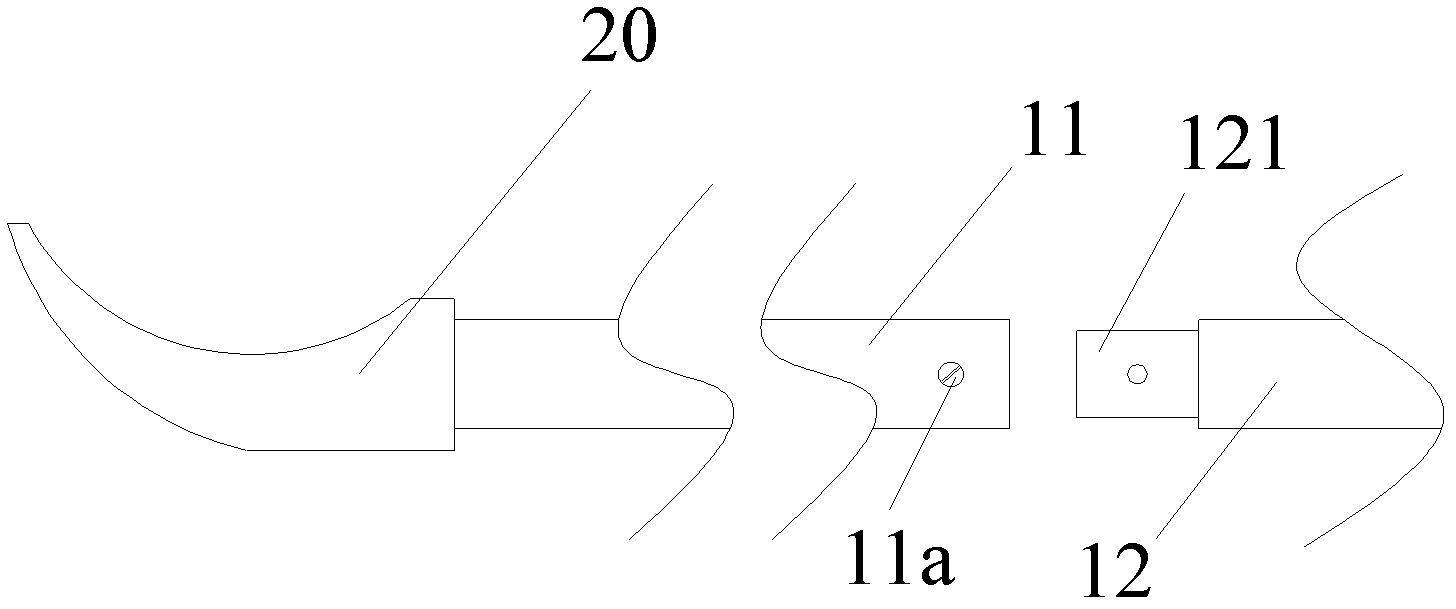

[0017] figure 1 shows a schematic side view of an embodiment of a stripping device according to the invention, figure 2 show figure 1 The schematic diagram of the front view of the peeling device, see in conjunction with Figure 1 to Figure 2 , it can be seen from the figure that the peeling device of this embodiment includes: an operating rod 10 and a peeling part 20 . Wherein, the stripping portion 20 is disposed at one end of the operating rod 10 , and the stripping portion 20 has a stripping through hole 21 . The stripping device of the present embodiment places the part of the metal sheath that needs to be stripped in the stripping through hole 21, rotates the operating lever 10, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com