Automatic detection alarm method and device for clogging of high pressure airtight filter

A filter clogging and automatic detection technology, applied in chemical instruments and methods, fixed filter element filters, filtration separation, etc., can solve the problem of limited ability of high-pressure airtight filters to collect and filter cuttings, damage to throttle manifold valves , pressure damage and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

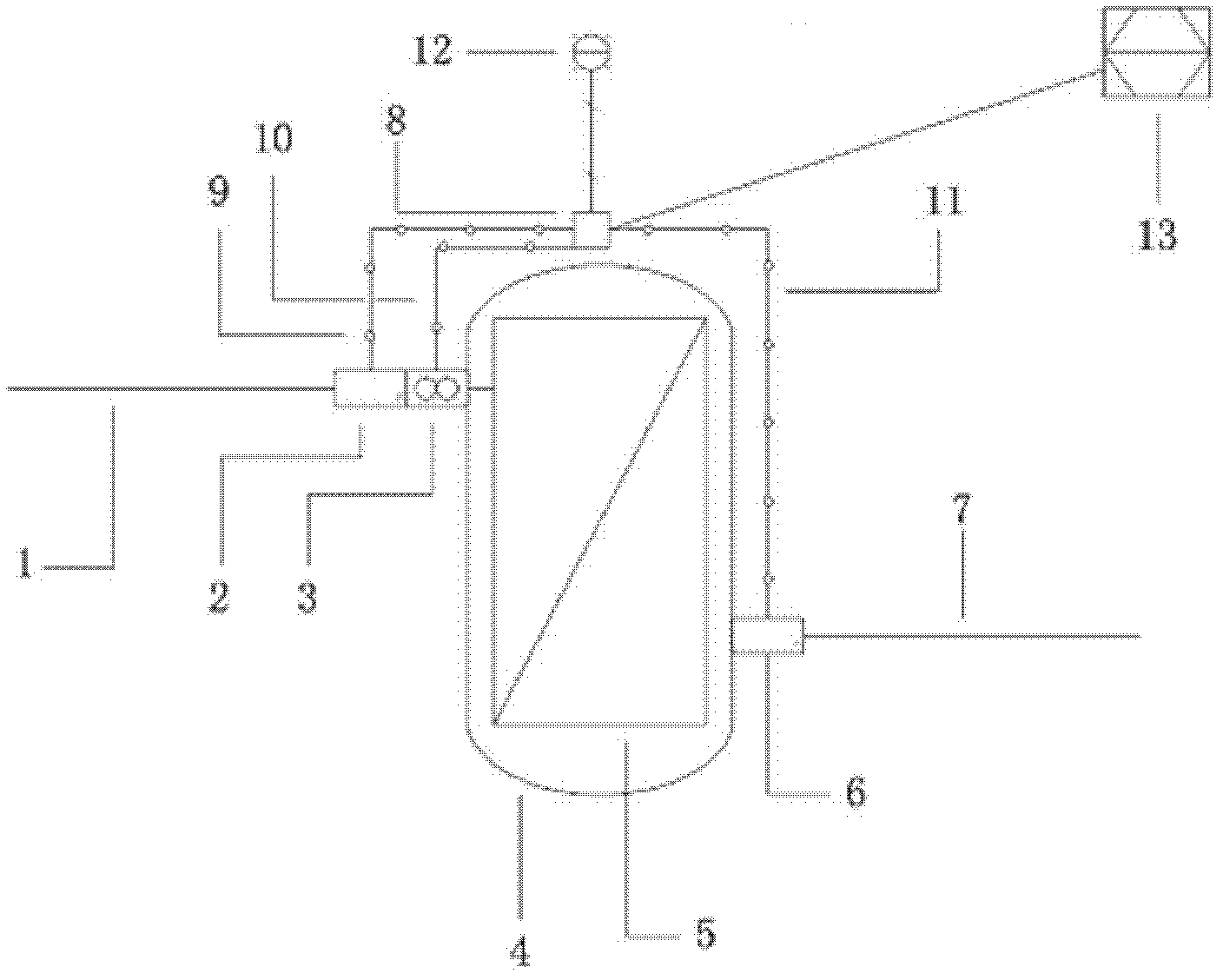

[0032] With reference to the accompanying drawings, the embodiments of the present invention are further described:

[0033] (1) Install the inlet pressure detector 2 and the inlet mass flowmeter 3 on the inlet passage 1 of the high-pressure hermetic filter, and install the outlet pressure detector 6 on the outlet passage 7 of the high-pressure hermetic filter. Connect the inlet pressure detector 2, the inlet mass flowmeter 3 and the outlet pressure detector 6 to the corresponding signal input ports of the core controller 8 through the signal lines 9, 10 and 11 respectively, and then connect the sound and light alarm 12 and the computer 13 to the The core controller 8 is connected. A filter net 5 is set in the high-pressure hermetic filter 4 . (If you do not need a computer to monitor the working status of this device, you can also choose not to connect to the computer).

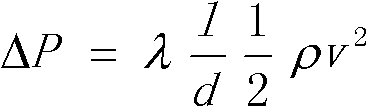

[0034] (2) On the core controller 8, choose to use the "experimental experience to set the blockage ala...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com