Replacing high-density vertical lifting parking equipment with comb crossing

A kind of parking equipment and high-density technology, which is applied in the direction of buildings, building types, and buildings where cars are parked. It can solve the problems of low vehicle density of the overall parking equipment, the inability to set up two or more parking spaces, and high equipment costs. The effect of improving space utilization efficiency, increasing vehicle density, and increasing the number of parking spaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

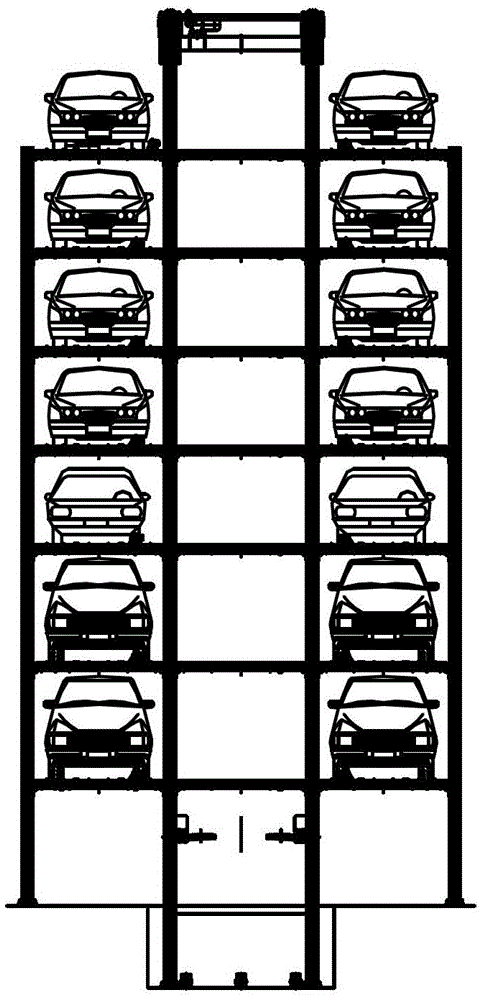

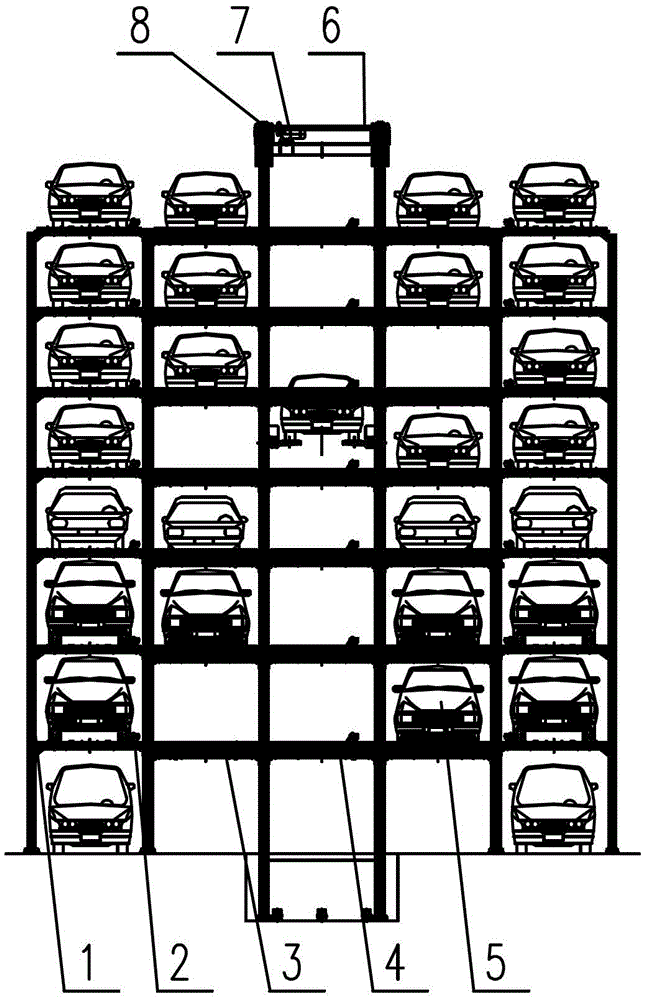

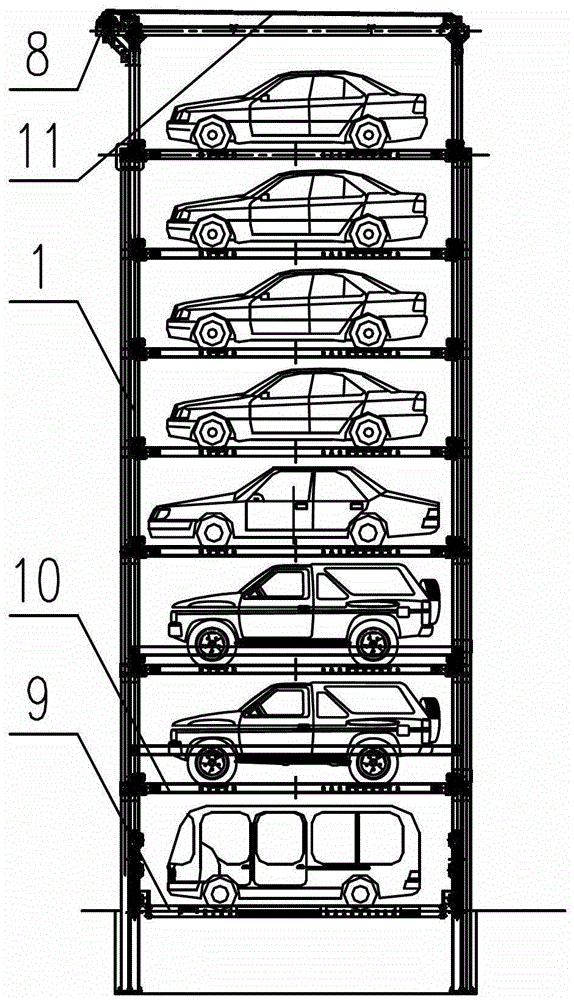

[0039] see Figure 2-16 , the high-density vertical lifting type parking equipment that the present invention relates to cross-connection replacement, mainly consists of a steel structure frame 1, a long raceway 2 for an outer parking space, a short raceway 3 for an inner parking space, a hoistway raceway 4, and a comb on the parking space 5. The toothed vehicle-carrying plate 10, the lifting drive device, the lifting carrier 9 and the like are composed. The steel structure frame 1 of the parking equipment is composed of columns, longitudinal beams, beams, etc., and the long raceway 2 for the outer parking space is composed of a raceway body 12, a deceleration drive motor 13, a sprocket wheel 14, a chain 15, and a roller 16. The long raceway 2 rests on the steel structure frame 1 of the parking equipment at the front and rear ends of the parking space 5. The raceway body 12 can be provided with an integral or segmented structure, arranged in layers according to the parking spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com