Device for pasting films on color profiles

A film sticking device and profile technology, which is applied to windows/doors, special equipment for doors/windows, building components, etc., can solve the problems of long adjustment time, easy to cause safety accidents, and low quality of the film on the surface of colored profiles, so as to achieve flexible adjustment. The effect of convenience, high film quality and large operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

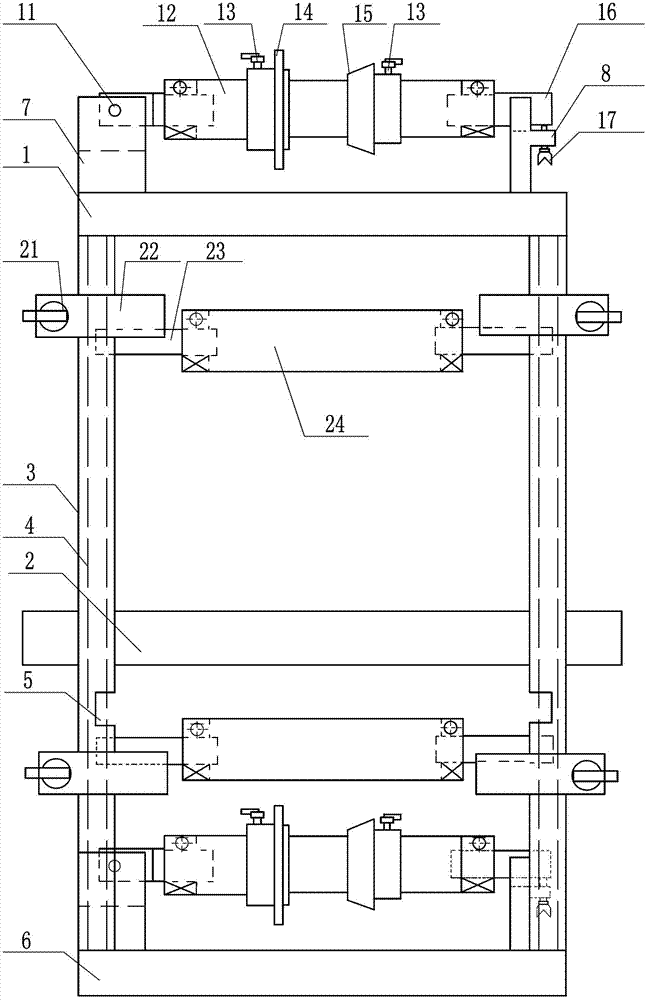

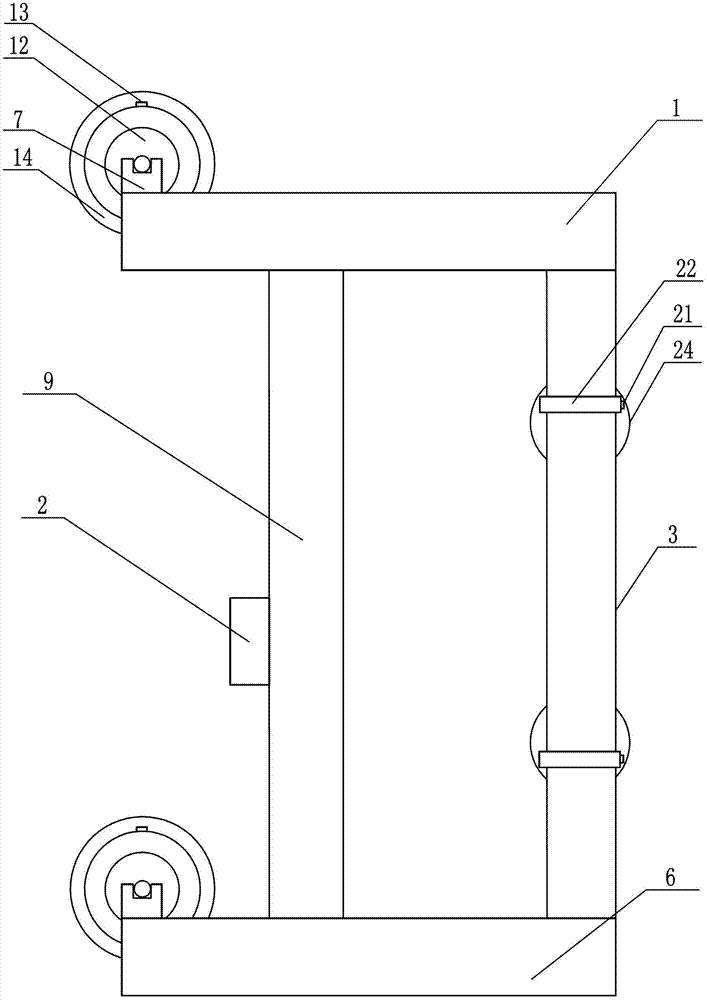

[0011] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] like figure 1 , figure 2 A color profile film sticking device shown includes an upper bracket 1, a protective film fixing roller 12, a protective film bonding roller 24, a hollow conduit 3, a support rod 9 and a base 6, and the upper bracket 1 and the front part of the base 6 are left and right. The ends are connected by two hollow conduits 3, and the left and right ends of the rear are connected by two support rods 9. The upper bracket 1 and the base 9 are provided with protective film fixing rollers 12, and the hollow conduit 3 is provided with two Protective film bonding roller 24; the rear portion of the upper bracket 1 and the base 9 are provided with a left support frame 7 and a right support frame 8, and the left support frame 7 passes through the transmission short shaft 16 at the left end of the protective film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com