Method for controlling a torque converter clutch device

A clutch device, torque converter technology, applied in the direction of transmission, transmission control, fluid transmission, etc., can solve the driver's discomfort and other problems, and achieve the effect of convenient wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

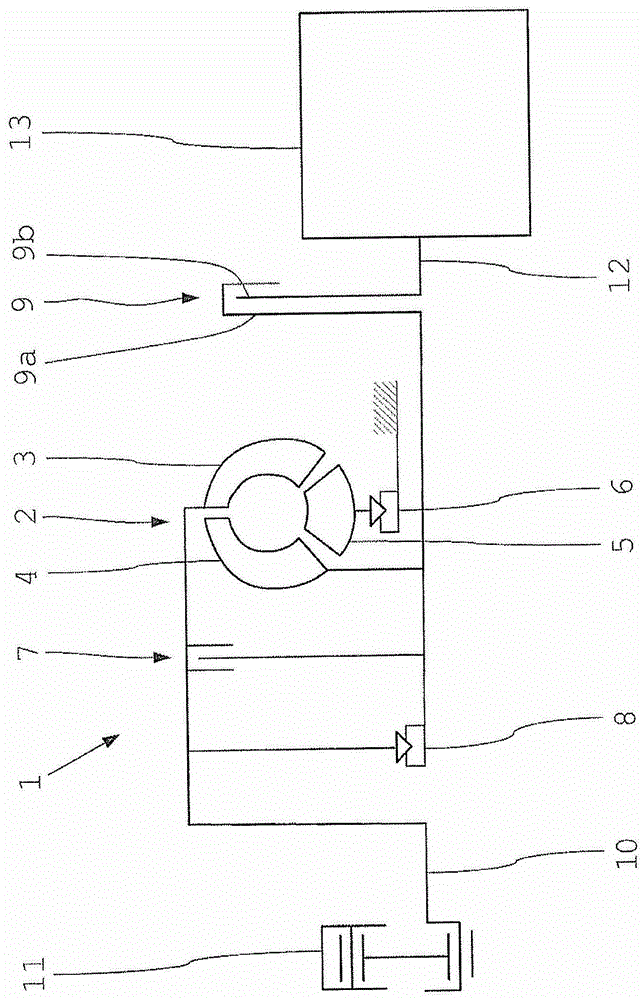

[0026] Such drivetrains for heavy-duty traction vehicles with a combination of a torque converter clutch and an automatic transmission are known per se. The torque converter clutch device 1 includes a hydraulic torque converter 2 , an automatically actuatable lock-up clutch 7 , a freewheel 8 and a shift clutch 9 . The lock-up clutch 7 and the shift clutch 9 are designed as friction clutches.

[0027] The torque converter 2 has a pump wheel 3 , a turbine wheel 4 and a guide wheel 5 in an oil-filled housing (not shown). The pump wheel 3 is connected to a drive shaft 10 or transmission shaft of a drive motor 11 designed as an internal combustion engine. The turbine wheel 4 is connected to the input side 9 a of the gearshift clutch 9 . The output side 9 b of the shift clutch 9 is connected to a transmission input shaft 12 of an automatic transmission 13 . The guide wheel 5 of the torque converter 2 is arranged between the pump wheel 3 and the turbine wheel 4 and is arranged mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com