Adjusting structure of magnetic belt conveying device

A transport device and structure adjustment technology, which is applied in the field of adjustment structure of the magnetic belt transport device of the coiler, and can solve problems such as uneven edges of the inner ring of the steel coil of the coiler, insufficient tension of the belt, and difficulty in introducing strip steel, etc. , to achieve the effect of novel structure, simple structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

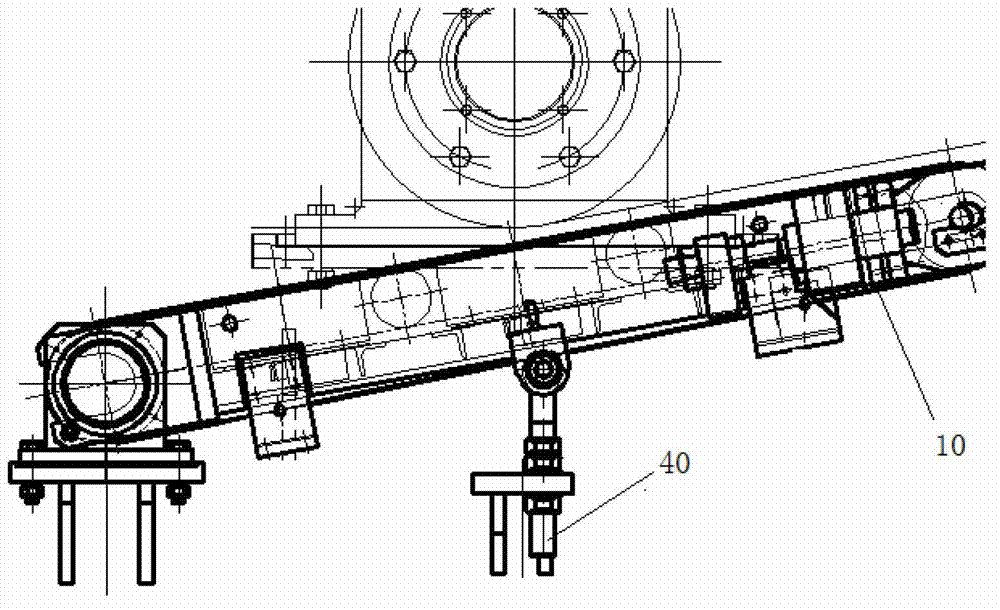

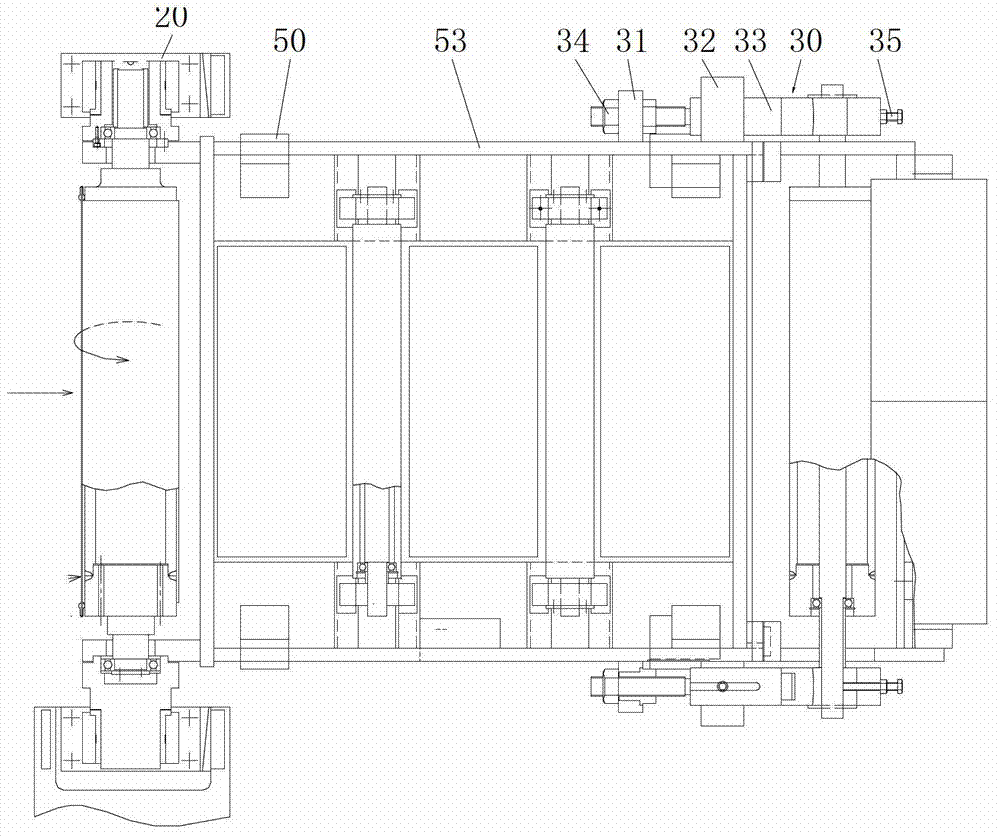

[0035] refer to figure 1 and figure 2 , the adjustment structure of the magnetic belt conveyor of the present invention includes a frame 10, a drive roller eccentric adjustment mechanism 20 arranged on the frame 10, a driven roller eccentric adjustment mechanism 30, a frame inclination angle adjustment mechanism 40 and a belt anti-shake adjustment mechanism 50 , each part is described in detail below:

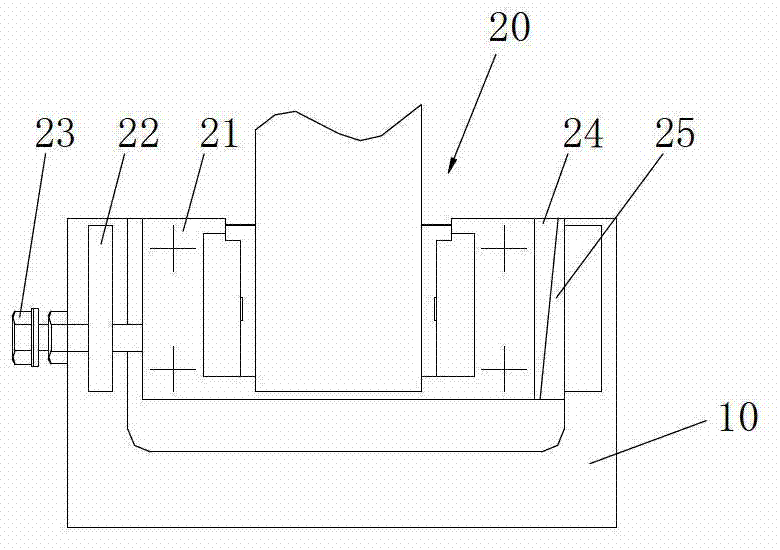

[0036] refer to figure 2 and image 3 , The driving roller eccentric adjustment mechanism 20 includes a driving roller bearing housing 21 , a thickness adjusting device, a vertical plate 22 and a fine-tuning bolt 23 . The driving roller bearing seat 21 is fixed on the frame by screws, and a bar-shaped hole is provided on the frame 10, through which the position of the driving roller bearing seat 21 fixed on the frame can be adjusted. The thickness adjustment devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com